PGA-enhanced degradable film and preparation method thereof

A technology for degrading films and polyesters, applied in the field of polymer materials, can solve the problems of restricting large-scale industrial applications, slow crystallization and hydrolysis speed, etc., achieve good water vapor barrier performance, improve compatibility, and strong hydrophilicity and the effect of polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

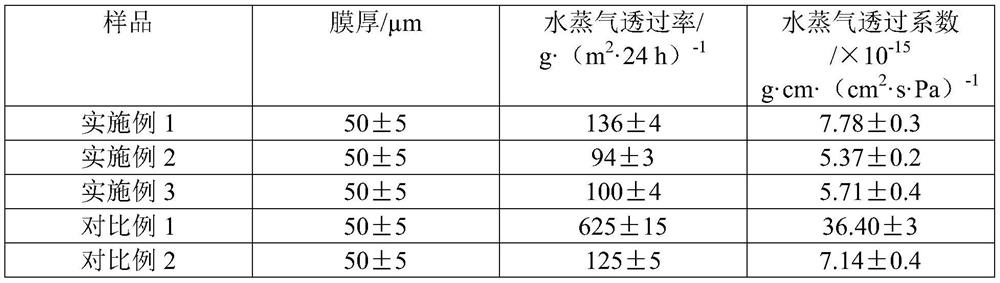

Examples

preparation example Construction

[0026] The preparation method of the degradable film reinforced by PGA according to the present invention comprises the following steps: (1) degradable polyester, polyglycolic acid, bio-based filler are dried at 60-80°C for 2-4h; Mix at 60-80°C for 2-4 hours; (3) Put the degradable polyester, the polyglycolic acid, the bio-based filler, the chain extender, and the plasticizer into a high-speed mixer according to the proportion and mix them evenly , wherein the mixing speed is 2000-3000rpm, and the mixing temperature is 70-90°C; (4) Put the above-mentioned compound into a twin-screw extruder to extrude and use a granulator to granulate, wherein the temperature is below 200-230°C Extrude at a speed of 100-200rpm, and pass through a pelletizer to obtain a composite material masterbatch; (5) Use a blow molding machine to blow mold the obtained composite material masterbatch.

[0027]In one embodiment of the preparation method of the PGA-enhanced degradable film according to the pr...

Embodiment 1

[0030] This example provides a method for preparing a PGA-enhanced degradable film: (1) Dry polylactic acid, polyglycolic acid, and starch at 80°C for 4 hours; (2) Mix citric acid and glycerin at a ratio of 1:1 After uniformity, heat at a constant temperature of 80°C for 3 hours; (3) According to the proportioning ratio, 100 parts of polylactic acid, 10 parts of polyglycolic acid (PGA), 25 parts of starch, 0.5 parts of chain extender 2-imidazolidinone, and 10 parts of plasticizer citric acid and glycerin Put one part into a high-speed mixer and mix evenly, wherein the mixing speed is 2500rpm, and the mixing temperature is 80°C; (4) Put the above-mentioned mixture into a twin-screw extruder to extrude and use a granulator to granulate, wherein the temperature is 220 Extrude at a speed of 150rpm at ℃, and pass through a pelletizer to obtain a composite material masterbatch. (5) Blow molding the obtained composite material masterbatch by using a blow molding machine.

Embodiment 2

[0032] This example provides a method for preparing a PGA-enhanced degradable film: (1) Dry polylactic acid, polyglycolic acid, and starch at 80°C for 4 hours; (2) Mix citric acid and glycerin at a ratio of 1:1 After uniformity, heat at a constant temperature of 80°C for 3 hours; (3) According to the proportion of 100 parts of polylactic acid, 20 parts of polyglycolic acid (PGA), 25 parts of starch, 0.5 parts of chain extender 2-imidazolidinone, plasticizer citric acid and glycerin 10 parts Put one part into a high-speed mixer and mix evenly, wherein the mixing speed is 2500rpm, and the mixing temperature is 80°C; (4) Put the above-mentioned mixture into a twin-screw extruder to extrude and use a granulator to granulate, wherein the temperature is 220 Extrude at a speed of 150rpm at ℃, and pass through a pelletizer to obtain a composite material masterbatch. (5) Blow molding the obtained composite material masterbatch by using a blow molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com