Pressure type dyeing method for textile fabric

A dyeing method and technology for textile fabrics, applied in the field of dyeing, can solve the problems of low dyeing efficiency, slowness, and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

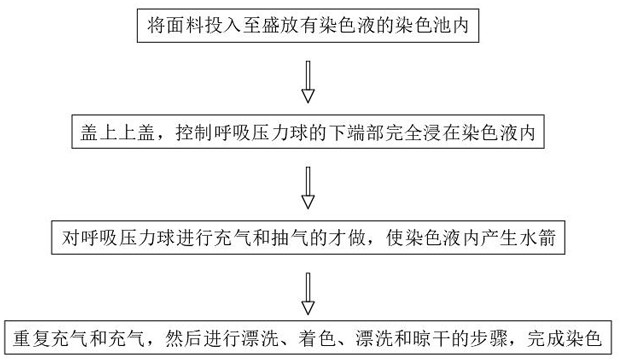

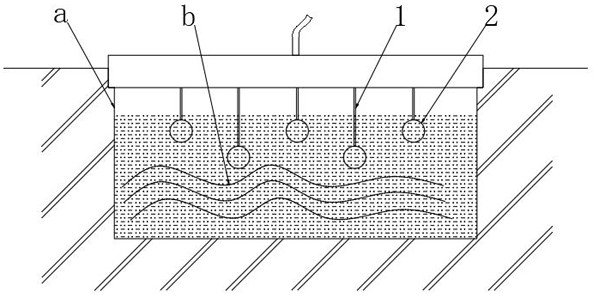

[0045] see figure 1 , a in the figure represents the dyeing pool, and b represents the fabric, a pressure dyeing method for textile fabrics, comprising the following steps:

[0046] S1. First, pre-treat the fabric for singeing and desizing treatment, then put the pre-treated fabric into the dyeing tank containing the dyeing solution, soak and color, the dyeing solution is in a high temperature state, and its temperature is 80 -95°C;

[0047] S2, cover the upper cover of the dyeing pool with a plurality of breathing pressure balls, and control the lower end of the breathing pressure balls to be completely immersed in the dyeing solution;

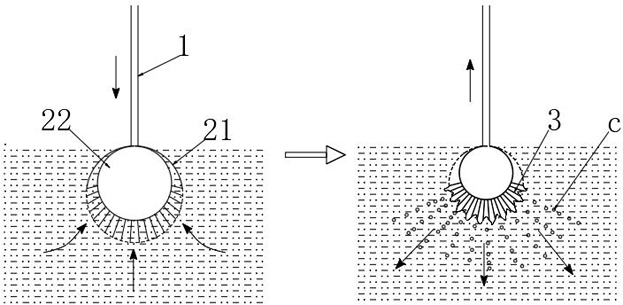

[0048] S3. Inflate multiple breathing pressure balls through the trachea above the upper cover, so that the lower end of the breathing pressure balls expands and stretches, so that the dyeing solution quickly enters the interior, and then quickly pumps air through the trachea to make the breathing pressure balls The lower end shrinks quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com