On-line monitoring method for end insulation state of inverter driving motor

A technology for end insulation and driving motors, which is applied in the direction of motor generator testing, instruments, and electrical measurement. It can solve the problems that the insulation state does not change much, and the insulation state and monitoring of the end of the motor winding cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

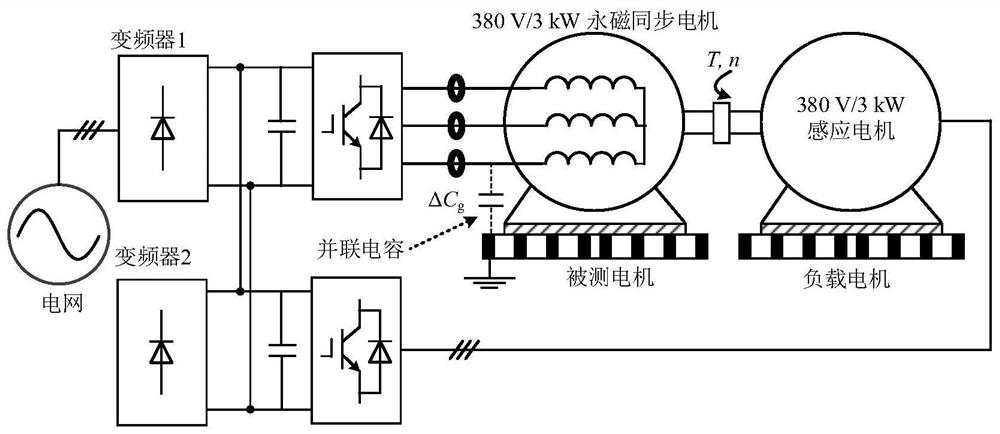

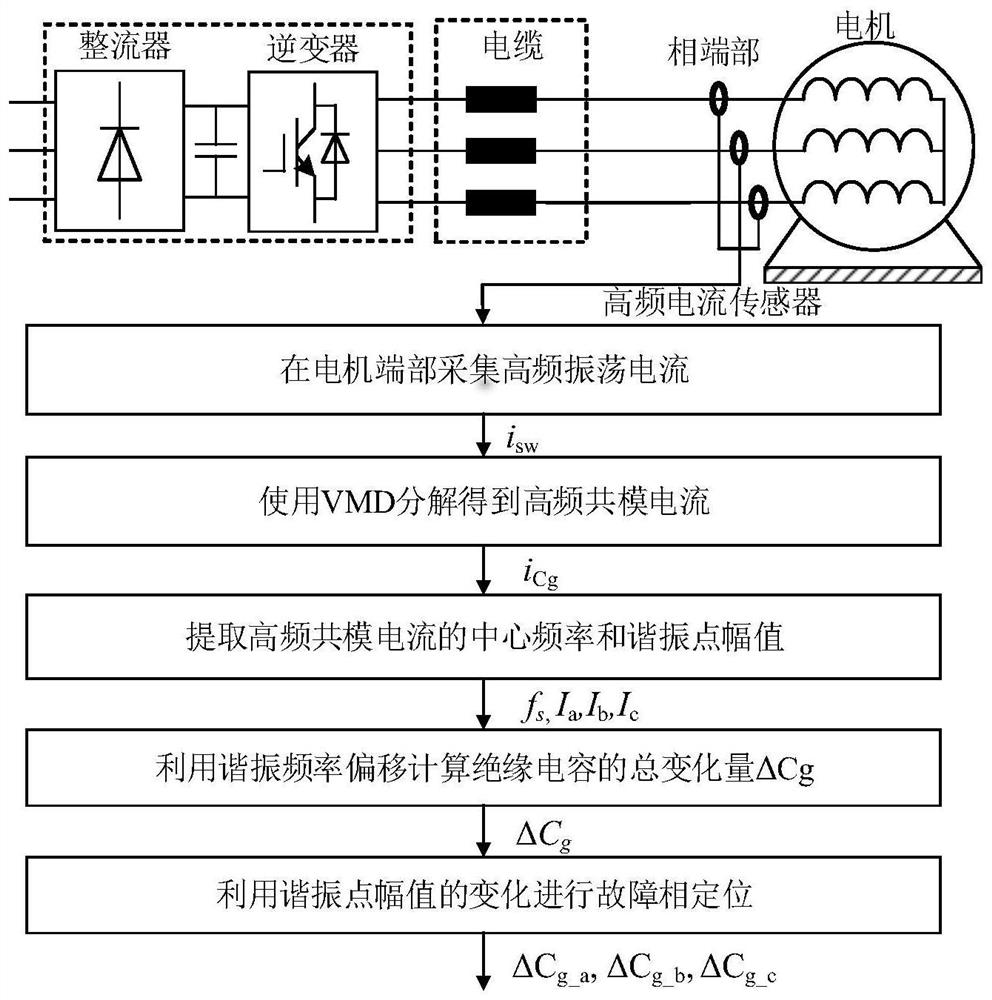

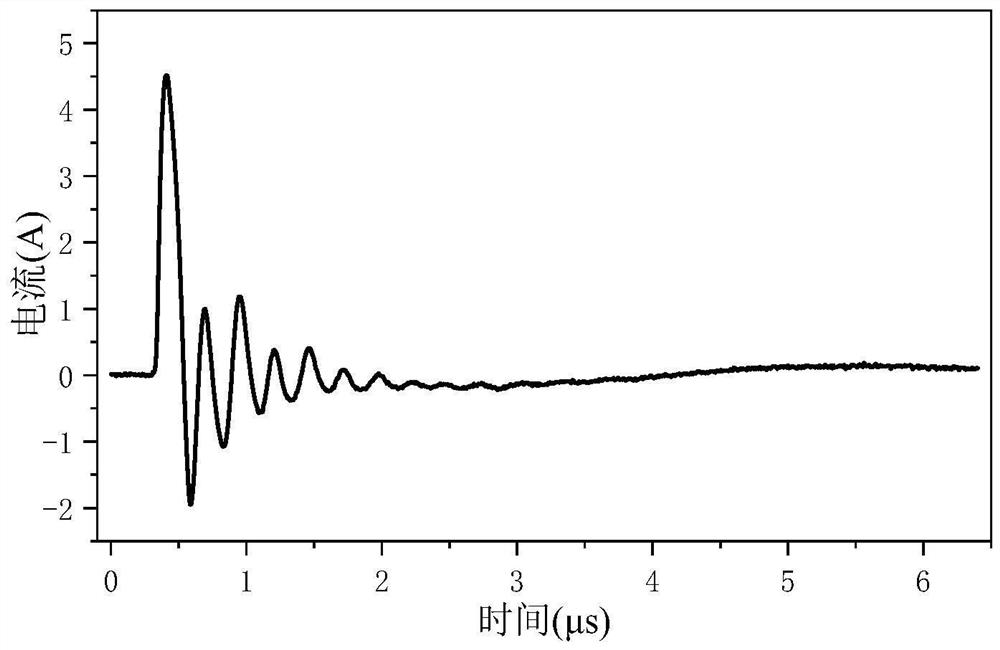

[0038] The present invention relates to an online monitoring method for the end insulation state of an inverter-driven motor. In this embodiment, a method such as figure 1The experimental bench shown. The motor under test in the experiment is an 8-pole 380V, 3kW permanent magnet synchronous motor (PMSM). The load motor adopts a 380V, 3kW induction motor (IM). Two frequency converters control the permanent magnet synchronous motor and the induction motor in speed mode and torque mode respectively. A high-speed signal acquisition unit (Pico 5444D, 14 bits, 125MS / s) and a host computer are used for signal acquisition and processing. Use a high-frequency differential probe CYBERTEK DP6150A (100MHz bandwidth) to measure the motor terminal voltage. A high-frequency current probe CYBERTEK CP8030B with a bandwidth of 50MHz is used to measure the motor current. Three current probes are arranged at the three-phase ends of the motor to collect the current signals including high-frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com