Transparent flexible electrode with ordered grid structure and preparation method and application thereof

A flexible electrode and grid structure technology, applied in ohmic resistance electrodes, cable/conductor manufacturing, circuits, etc., can solve the problems of oxidation, electrode performance degradation, electrode material easy to fall off, etc., to achieve extended application methods, simple preparation process, The effect of improving light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

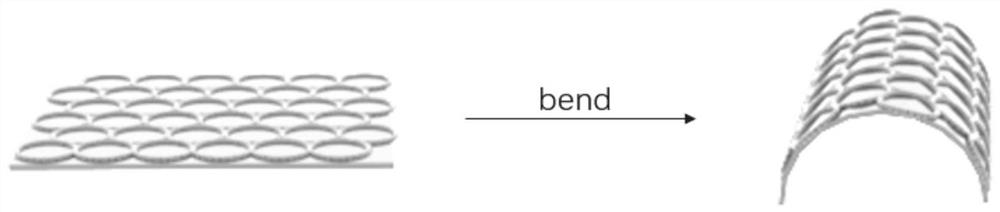

[0040] One or more embodiments of the present invention also provide a method for preparing a transparent flexible electrode based on an ordered ring structure of metal nanowires embedded in a PET substrate. The preparation method includes the following steps: Spray the silver nanowire solution, self-assemble after the silver nanowire solution is dried to obtain an ordered ring structure, then spin coat a layer of PET solution, heat to solidify the PET, and peel off the PET film and PTFE film after cooling to obtain the transparent flexible electrodes.

[0041] The silver nanowire solution is an aqueous solution containing silver nanowires, an organic solution or a mixture of water and an organic solution; preferably, the organic solution is an ethanol or methanol solution containing silver nanowires.

[0042] The concentration of the silver-containing nanowire solution is 0.001-10 mg / ml;

[0043] The silver-containing nanowire solution is sprayed on the surface of the PTFE f...

Embodiment 1

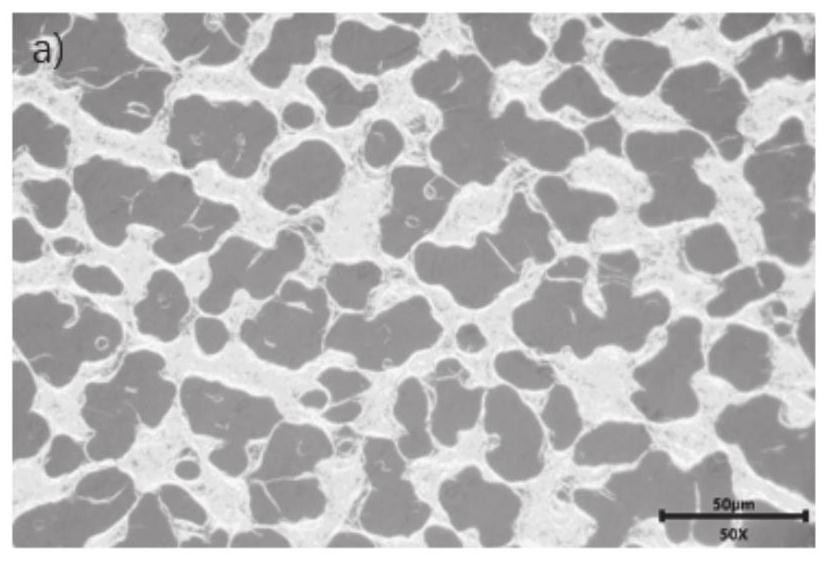

[0052] This embodiment provides a transparent flexible electrode based on an ordered ring structure metal nanowire embedded in a PET substrate. The preparation method of the transparent flexible electrode includes:

[0053] Step 1: Select silver nanowires with a diameter and length of 30nm and 20um respectively and add them into ethanol to form an AgNWs solution with a concentration of 0.5mg / ml. Add the AgNWs solution to the spray gun. The nozzle diameter is 0.3mm, and the spray distance is 7cm;

[0054] Step 2: Spray nano-silver solution on the surface of PTFE film, and self-assemble to obtain an ordered ring structure after the nano-silver is dried;

[0055] Step 3: Dissolve 1.5g of PET particles in 6ml of trifluoroacetic acid (TFA) and 12ml of dichloromethane (DCM), add 4wt% transparent agent, and stir at 300rpm at room temperature for 2h to form a PET solution.

[0056] Step 4: Put the PTFE film on the glue homogenizer, spin coat a layer of PET solution at a speed of 200r...

Embodiment 2

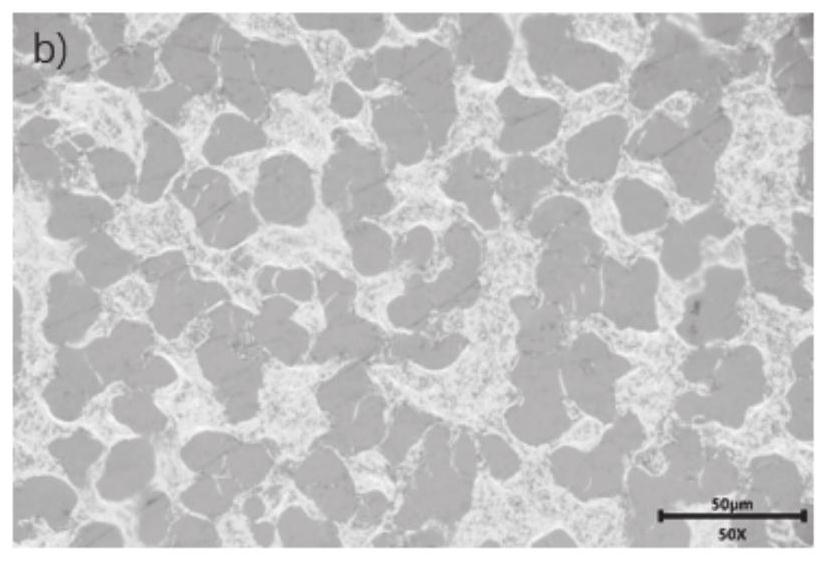

[0064] This embodiment provides a transparent flexible electrode based on an ordered ring structure metal nanowire embedded in a PET substrate. The preparation method of the transparent flexible electrode includes:

[0065] Step 1: Select silver nanowires with a diameter and length of 40nm and 50um respectively and add them to ethanol to form an AgNWs solution with a concentration of 0.3mg / ml. Add the AgNWs solution to the spray gun. The nozzle diameter is 0.4mm, and the spray distance is 8cm;

[0066] Step 2: Spray nano-silver solution on the surface of PTFE film, and self-assemble to obtain an ordered ring structure after the nano-silver is dried;

[0067] Step 3: Dissolve 2g of PET particles in 6ml of trifluoroacetic acid (TFA) and 12ml of dichloromethane (DCM), add 4wt% transparent agent, and stir at 300rpm at room temperature for 2h to form a PET solution.

[0068] Step 4: Put the PTFE film on the glue homogenizer, spin coat a layer of PET solution at a speed of 200rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com