Process for integrating preparation and loading of catalyst layer in oxygen cathode membrane electrode

A catalytic layer and membrane electrode technology, which is applied in the field of electrospinning to realize the integration of the preparation and loading of the catalytic layer in the oxygen cathode membrane electrode, can solve the problem of excessive production and processing processes of the oxygen cathode membrane electrode, and achieve a streamlined The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

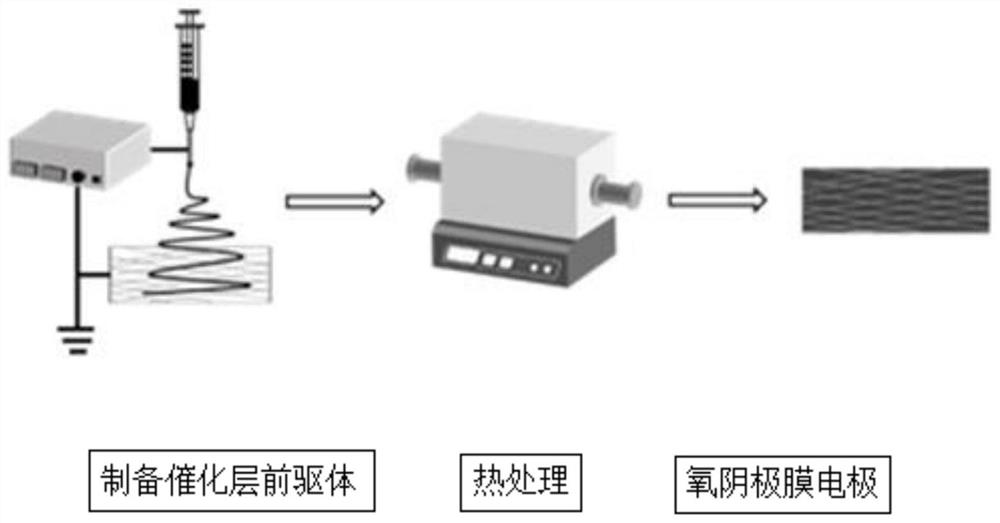

[0025] according to figure 1 The process flow shown carries out the fabrication of bilayer components. Weigh 0.80mmol Fe(NO3)3·9H2O, 0.30g glucose, 1.00g polyacrylonitrile, dissolve and disperse with 9.00g N,N-dimethylformamide solvent, and vigorously stir magnetically at room temperature for 12h to form a uniform solution.

[0026] The solution was placed in a solution electrospinning device for electrospinning, using an 18-caliber stainless steel needle with an inner diameter of 0.86mm, and the hydrophilic carbon paper was fixed on the roller receiver, and the injection rate was set at 0.30mL / h. The distance from the outlet to the roller is 20.00cm, the rotation speed of the roller is 600rpm, and the positive high voltage is set to 24.00kV.

[0027] The carbon paper loaded with the precursor was heat-treated, and the heating rate was 1 °C / min in the air atmosphere to 250 °C for 1 h, and then the heating rate was 5 °C / min in the atmosphere of argon to 450 °C for 1 h. Heat a...

PUM

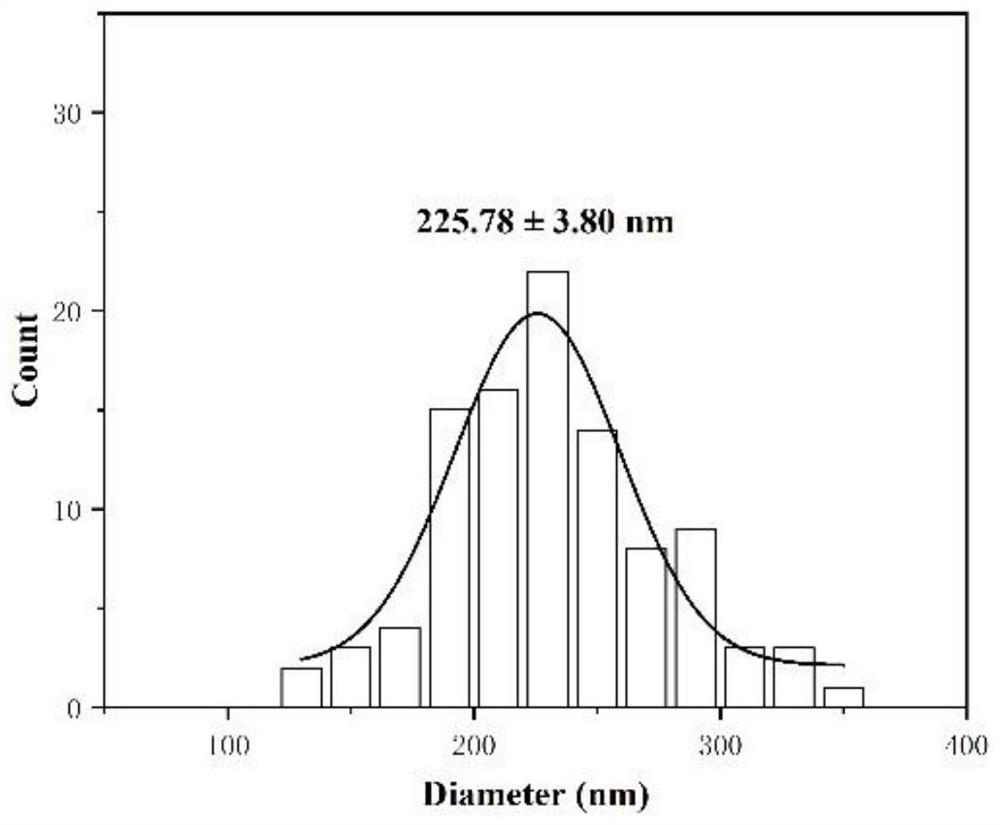

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com