Grain-oriented electrical steel sheet, method for forming insulative coating film for grain-oriented electrical steel sheet, and method for manufacturing grain-oriented electrical steel sheet

A technology of insulating film and electromagnetic steel sheet, which can be applied to manufacturing tools, circuits, magnetic objects, etc., and can solve the problems of difficulty in reducing iron loss, inability to guarantee the adhesion of insulating film, and difficult magnetic properties of base metal steel sheets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0260] Next, the effect of one solution of the present invention will be described in detail through an example, but the conditions in the example are an example of conditions adopted in order to confirm the practicability and effect of the present invention, and the present invention is not limited to this A condition example. The present invention can employ various conditions as long as the object of the present invention is achieved without departing from the gist of the present invention.

experiment example 1

[0262] The steel slab was heated to 1350° C. and hot-rolled to obtain a hot-rolled steel sheet with an average thickness of 2.3 mm. The steel slab contained C: 0.081% by mass, Si: 3.3% by mass, Mn: 0.083% by mass, and S: 0.022% by mass % (S+Se: 0.022% by mass), acid-soluble Al: 0.025% by mass, Cr: 0.04%, N: 0.008% by mass, Bi: 0.0025% by mass, and the remainder contains Fe and impurities.

[0263] The obtained hot-rolled steel sheet was annealed at 1100° C. for 120 seconds, and then pickled. The pickled steel plate was cold-rolled and finished to an average thickness of 0.23mm to make a cold-rolled steel plate. Thereafter, decarburization annealing was performed on the obtained cold-rolled steel sheet.

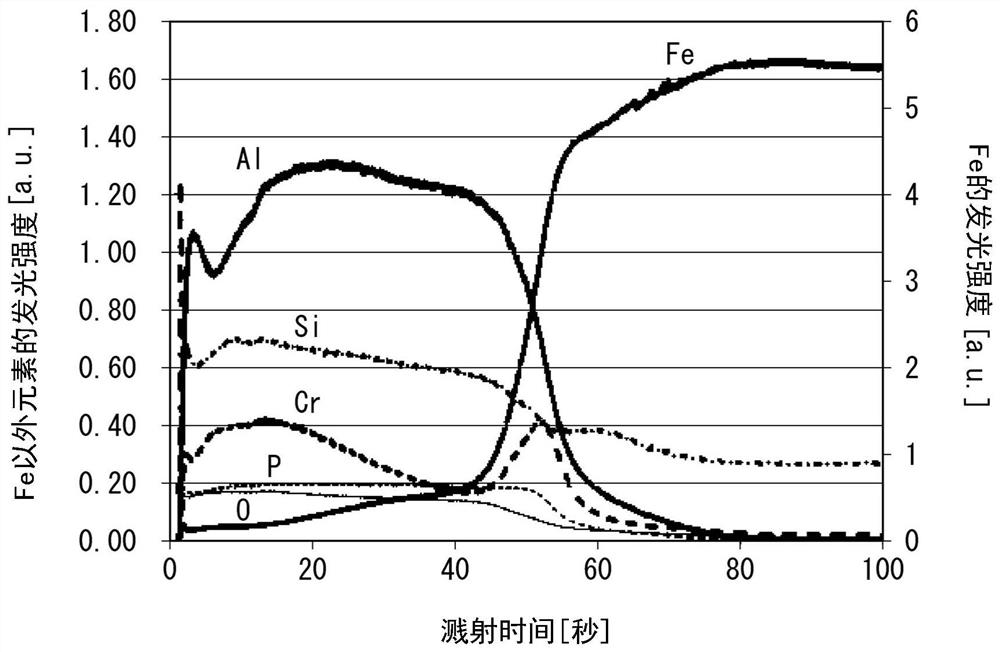

[0264] Thereafter, an annealing separator was applied and dried, and subjected to finished annealing at 1200° C. for 20 hours. The annealing separator was composed of a total of 95% by mass of MgO and Al in terms of solid content. 2 o 3 , MgO and Al 2 o 3 The mixing ratio...

experiment example 2

[0287] Steel slab A (steel slab A) and steel slab B (steel slab B) were respectively heated to 1350° C. and hot-rolled to obtain hot-rolled steel sheets with an average thickness of 2.3 mm. The steel slab A (steel slab A) contained C: 0.082 % by mass, Si: 3.3% by mass, Mn: 0.082% by mass, S: 0.023% by mass (S+Se: 0.023% by mass), acid-soluble Al: 0.025% by mass, Cr: 0.05%, N: 0.008% by mass, remaining Partly containing Fe and impurities, the steel slab B (steel slab B) contains C: 0.081% by mass, Si: 3.3% by mass, Mn: 0.083% by mass, S: 0.022% by mass (S+Se: 0.022% by mass), acid Soluble Al: 0.025% by mass, Cr: 0.04%, N: 0.008% by mass, Bi: 0.0025% by mass, and the remainder contains Fe and impurities.

[0288] Each obtained hot-rolled steel sheet was annealed at 1100° C. for 120 seconds, and then pickled. The pickled steel plate was finished by cold rolling to an average thickness of 0.23 mm to obtain a cold rolled steel plate. Thereafter, decarburization annealing was perf...

PUM

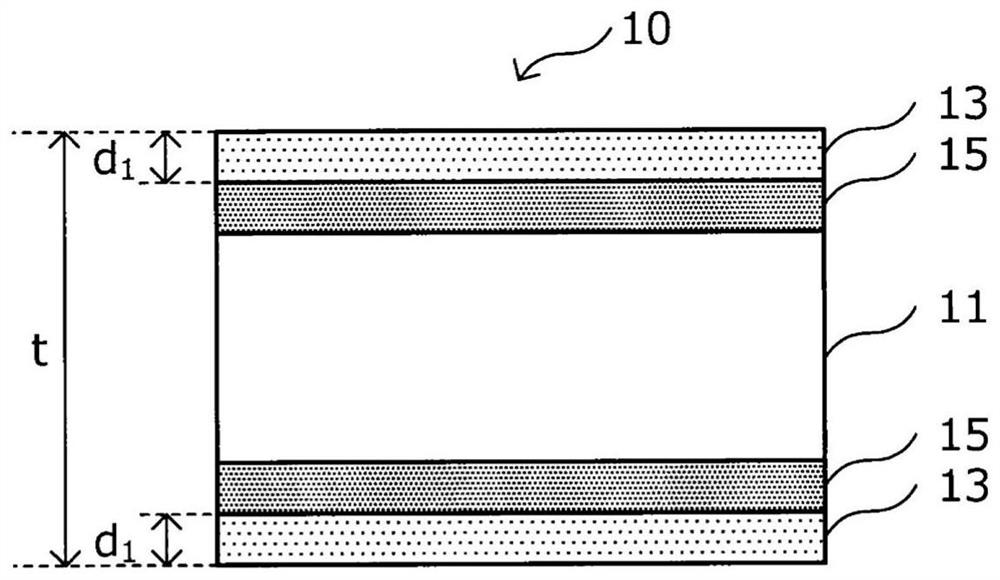

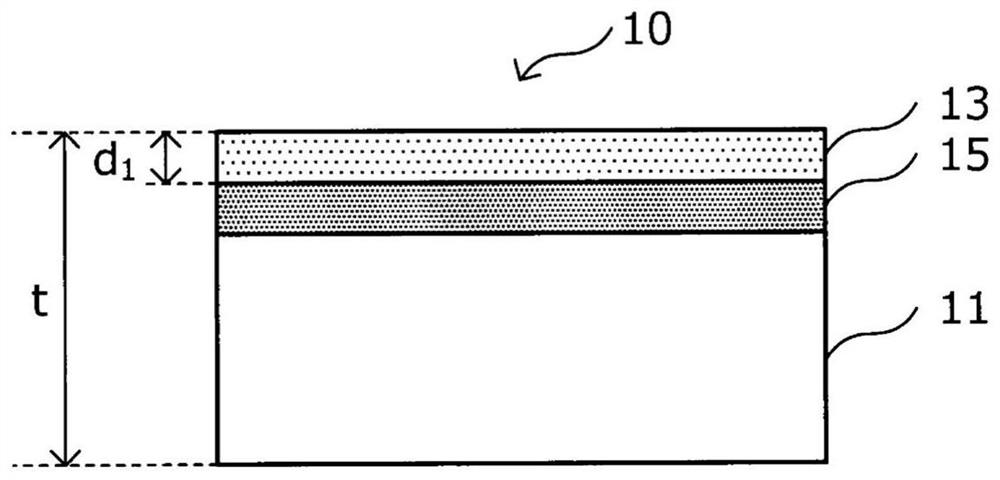

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com