Jam with long shelf life and production equipment of jam

A technology for production equipment and shelf life, which is used in food preservation, mixers with rotary stirring devices, and preservation of food ingredients as anti-microbials, etc. The price is convenient and easy to obtain, the quality is guaranteed, and the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

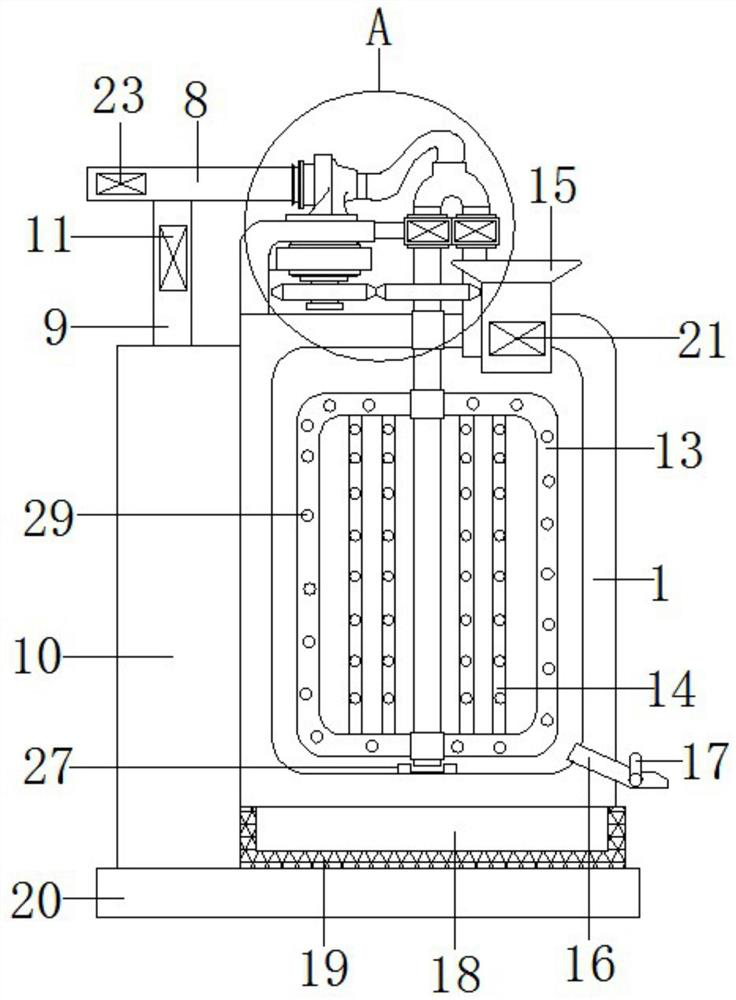

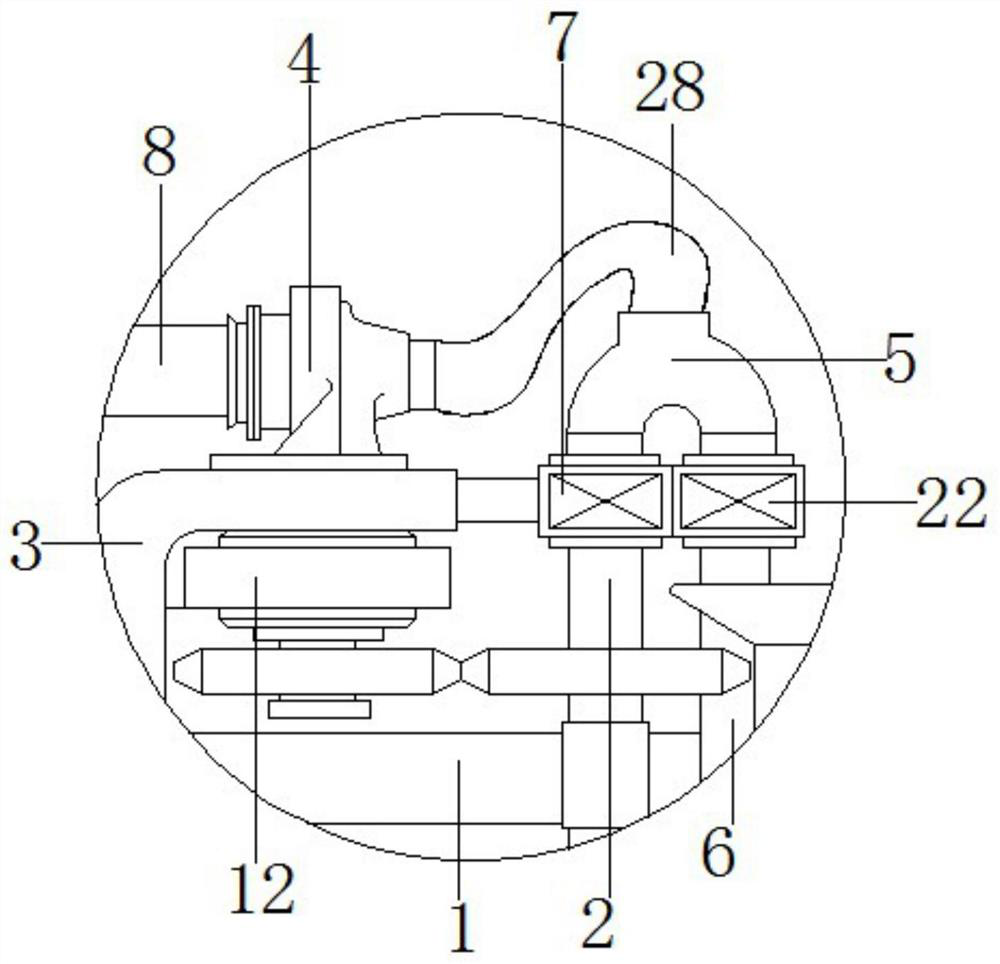

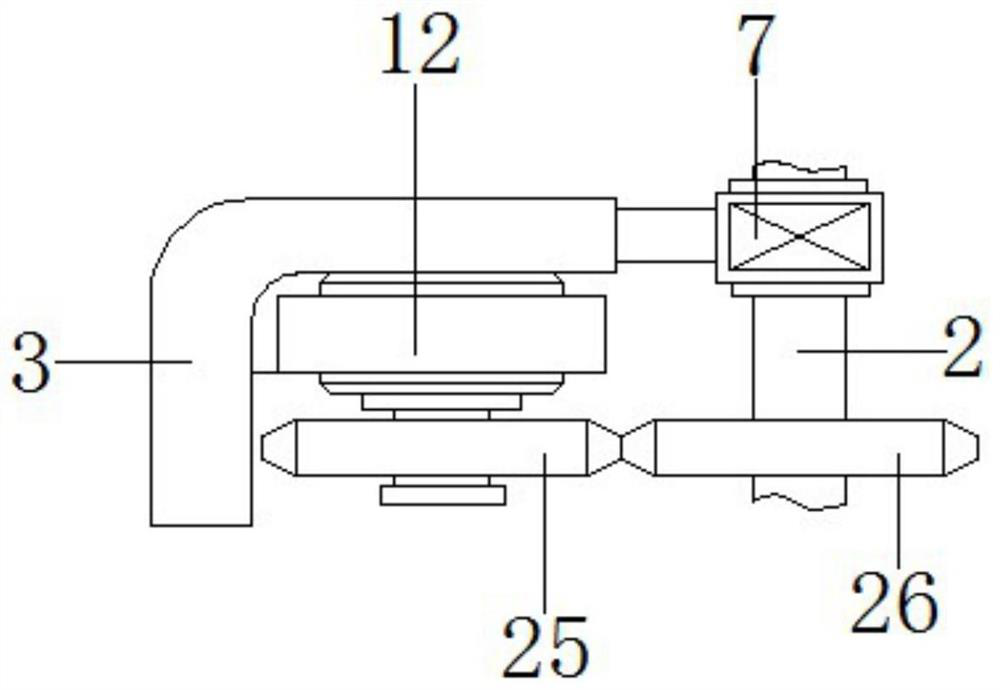

Image

Examples

Embodiment 1

[0036] A kind of jam with a long shelf life, its raw materials include 1 kg of strawberry, 0.1 kg of white granulated sugar, 0.3 kg of syrup, 0.2 kg of thickener, 0.02 kg of citric acid, appropriate amount of distilled water and nitrogen, and 1 kg of strawberry Dice the strawberries and put them into the tank, add distilled water, white sugar, syrup, thickener and citric acid in sequence for mixing, and inject nitrogen into the raw materials during the mixing process, the injection of nitrogen will replace the tank Body 1 and the oxygen stored inside the raw materials, reduce the oxygen content in the jam, and avoid the growth of bacteria and fungi.

Embodiment 2

[0038] A kind of jam with a long shelf life, its raw materials include 1 kg of apples, 0.15 kg of white granulated sugar, 0.4 kg of syrup, 0.3 kg of thickener, 0.01 kg of citric acid, appropriate amount of distilled water and nitrogen, and 1 kg of strawberry Dice the apples and put them into the tank, add distilled water, white sugar, syrup, thickener and citric acid in sequence for mixing, and inject nitrogen into the raw materials during the mixing process, because the density of apples is different from that of strawberries. Different, and the addition amount of various additives is different, so there is a certain difference in the density of the jam, so there is a certain difference in the nitrogen content stored in the jam.

[0039] The content of nitrogen will directly affect the shelf life of jam, and the mass ratio of white sugar and syrup in jam will directly affect the sweetness of jam. The higher the ratio of white sugar and syrup, the sweeter the jam, while the rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com