SiC whisker toughened Si3N4 ceramic pneumatic motor blade, preparation method and pneumatic motor

An air motor and whisker technology, applied in the field of ceramic materials, can solve the problems of short service life, poor toughness, low strength, etc., and achieve the effects of improving service life, denser texture and good thermal shock resistance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

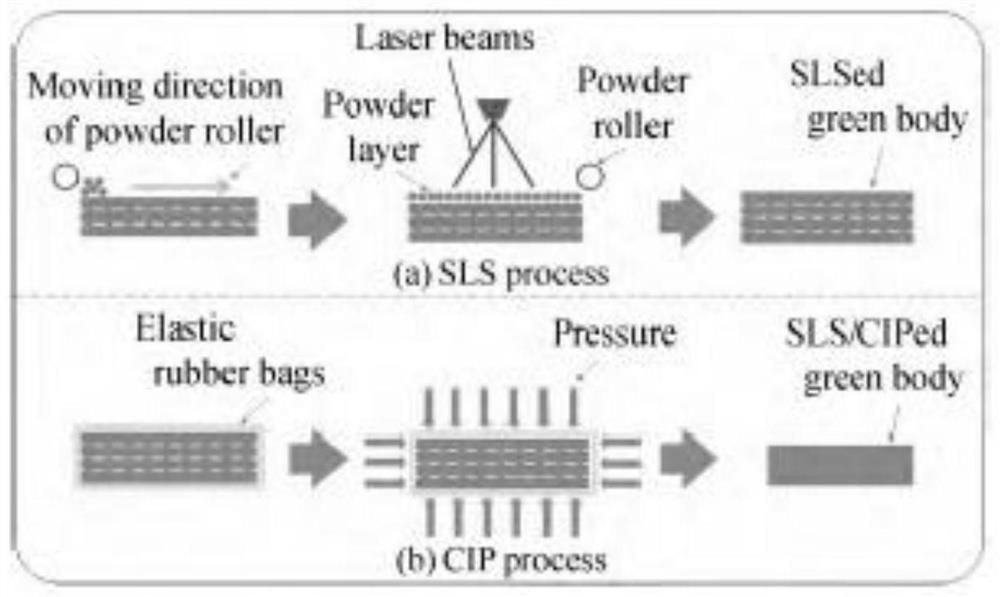

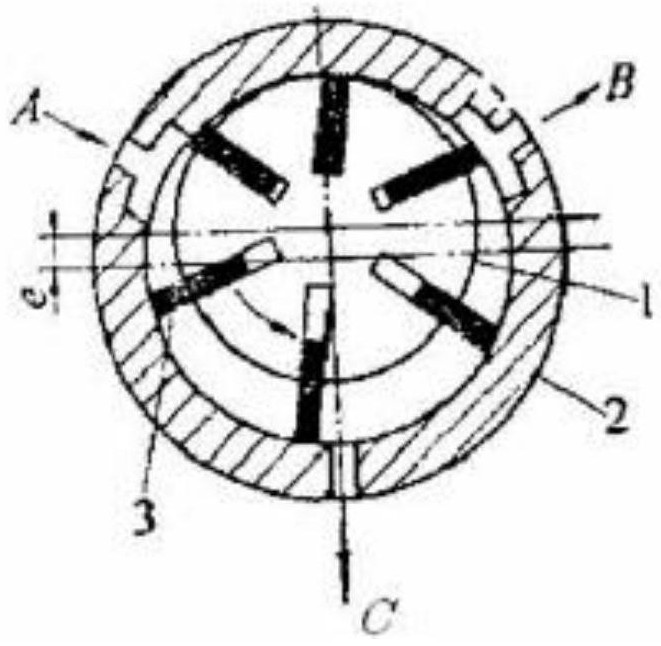

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a SiC whisker toughened Si 3 N 4 Ceramic air motor blades, the raw material is composed of the following components: Si 3 N 4 Ceramic base powder, SiC whisker, Y 2 o 3 , A1 2 o 3 , and epoxy resin; Si 3 N 4 Ceramic base powder as raw material, add 10wt% SiC whisker of raw material mass, 6wt% Y 2 o 3 , 4wt% A1 2 o 3 , the amount of epoxy resin is 35vol% of the total volume of the composite powder.

[0036] Si 3 N 4 Ceramic base powder is β-Si 3 N 4 ,D 50 = 6.59 μm.

[0037] SiC whiskers have a diameter of 0.1-1.0 μm and an aspect ratio >20.

[0038] The epoxy resin described in this example is a bisphenol A type epoxy resin. The molecular structure of this epoxy resin contains hydroxyl and ether bonds. The curing process further generates new -OH and -O-, so that the cured product has a strong High cohesion and adhesion.

[0039] In a specific embodiment, the type of the epoxy resin is E12, and the epoxy value is 0.10-0.18.

[00...

Embodiment 2

[0048] The invention provides a SiC whisker toughened Si 3 N 4 Ceramic air motor blades, the raw material is composed of the following components: Si 3 N 4 Ceramic base powder, SiC whisker, Y 2 o 3 , A1 2 o 3 , and epoxy resin; Si 3 N 4 Ceramic base powder as raw material, add 9wt% SiC whisker, 7wt% Y 2 o 3 , 3wt%A1 2 o 3 , the amount of epoxy resin is 38vol% of the total volume of the composite powder.

[0049] Si 3 N 4 Ceramic base powder is β-Si 3 N 4 ,D 50 = 8.0 μm.

[0050] SiC whiskers have a diameter of 0.1-1.0 μm and an aspect ratio >20.

[0051] The type of the epoxy resin described in this embodiment is E12, and the epoxy value is 0.10-0.18.

[0052] The embodiment of the present invention also provides the SiC whisker toughened Si 3 N 4 A method for preparing a ceramic air motor blade, comprising the following steps:

[0053] S1, take each component in proportion, Si 3 N 4 Ceramic base powder, SiC whisker, Y 2 o 3 , A1 2 o 3 Mix well, and...

Embodiment 3

[0059] The invention provides a SiC whisker toughened Si 3 N 4 Ceramic air motor blades, the raw material is composed of the following components: Si 3 N 4 Ceramic base powder, SiC whisker, Y 2 o 3 , A1 2 o 3 , and epoxy resin; Si 3 N 4 Ceramic base powder is used as a raw material, and 11wt% SiC whiskers, 7wt% Y 2 o 3 , 3wt%A1 2 o 3 , the amount of epoxy resin is 34vol% of the total volume of the composite powder.

[0060] Si 3 N 4 Ceramic base powder is β-Si 3 N 4 ,D 50 = 4.0 μm.

[0061] SiC whiskers have a diameter of 0.1-1.0 μm and an aspect ratio >20.

[0062] The type of the epoxy resin described in this embodiment is E12, and the epoxy value is 0.10-0.18.

[0063] The embodiment of the present invention also provides the SiC whisker toughened Si 3 N 4 A method for preparing a ceramic air motor blade, comprising the following steps:

[0064] S1, take each component in proportion, Si 3 N 4 Ceramic base powder, SiC whisker, Y 2 o 3 , A1 2 o 3 M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com