A plasma mass spectrometry ion focusing deflection sampling interface and working mode

A sampling interface and ion focusing technology, applied in electron/ion optical devices, particle separation tubes, sample introduction/extraction, etc., can solve problems such as low transmission efficiency, affecting sample ionization efficiency, and large ion loss, achieving high Effects of ion transmission efficiency, increased injection throughput, and back-end detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] It should be noted that the terms "first" and "second" in the description and claims of the present invention and the above drawings are used to distinguish similar objects, but not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the invention described herein can be practiced in sequences other than those illustrated or described herein. In addition, the terms "comprising" and "having" and any variations thereof in the embodiments of the present invention are intended to cover a non-exclusive inclusion, for example, a process, method, system, product or device comprising a series of steps or units is not necessarily limited to Those steps or elements are not explicitly listed, but may include other steps or elements not explicitly listed or inherent to the process, method, product or apparatus.

[0026] It is to be understood that ...

Embodiment approach 1

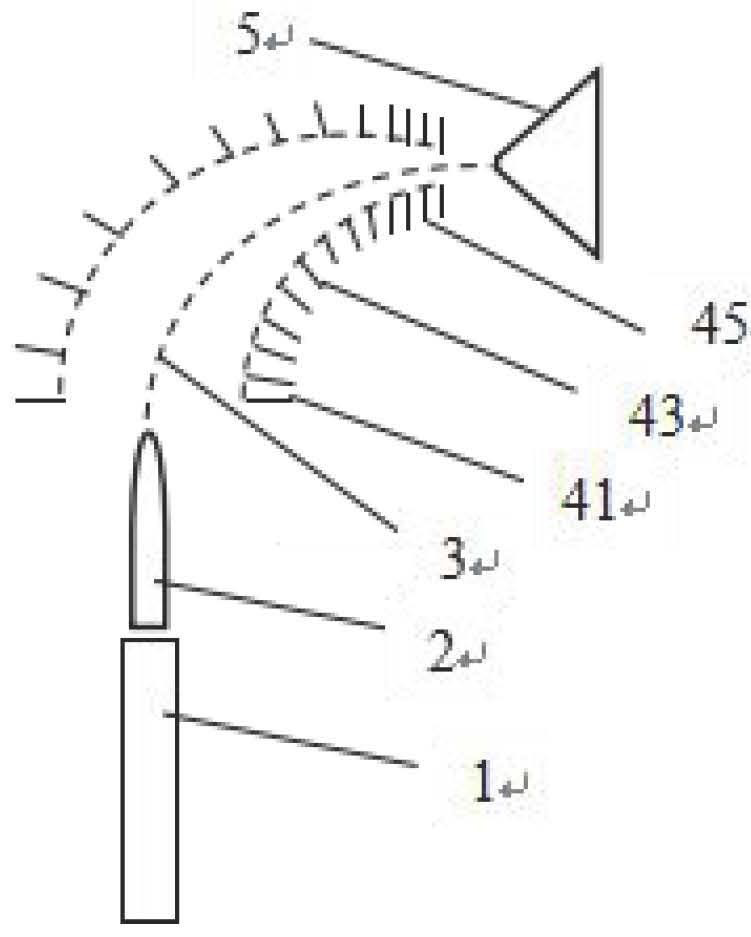

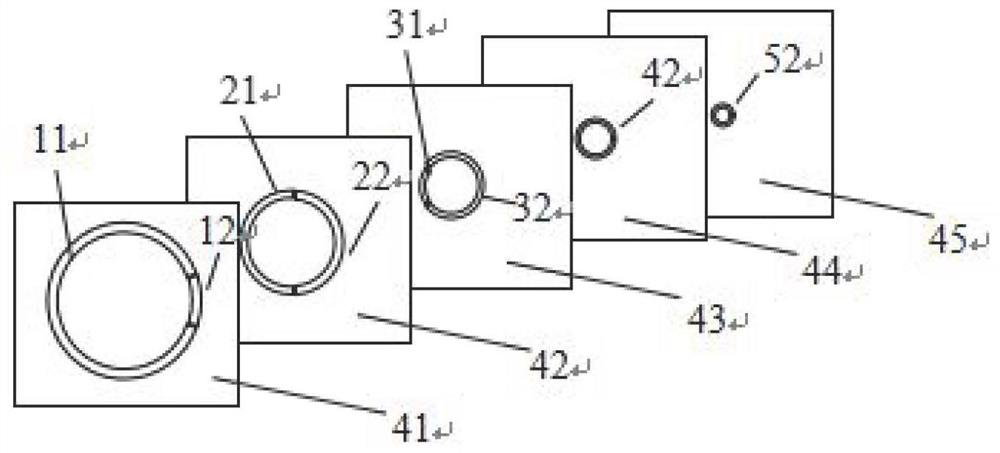

[0035] In the positive ion deflection working mode, a plasma mass spectrometry ion focusing deflection sample injection interface consists of a plasma source composed of a plasma torch 1 and a plasma flame 2, a focusing deflection plate group composed of several deflection plates, and a mass spectrometry sample injection interface. Interface composition. The plasma source is high-power microwave plasma or inductively coupled plasma. Taking partial focusing deflecting plates 41-45 arranged sequentially in the focusing deflecting plate group as an example, focusing deflecting plates 41-45 are a series of deflecting plates with a circular central channel, and each deflecting plate is distributed at a certain angle in the plasma flame 2 Between it and the mass spectrometry sampling interface 5, its central channel forms the ion transmission path 3 for ions to enter the mass spectrometry sampling interface from the source. The dimensions of the central channels of the focusing def...

Embodiment approach 2

[0038] In the negative ion deflection working mode, a plasma mass spectrometer ion focusing deflection sampling interface consists of a plasma source composed of a plasma torch 1 and a plasma flame 2, a focusing deflection plate group composed of several deflection plates, and a mass spectrometry sampling interface composition. The plasma source is a low-power microwave plasma, and the structure of the focusing deflection plasma mass spectrometry sampling interface is the same as that in Embodiment 1. Taking the focus deflection plates 41-45 arranged sequentially in the focus deflection plate group as an example, the electrodes 11, 21 and 31 on them are loaded with a voltage of U 11 , U 21 and U 31 , the loading voltage on the electrodes 12~52 is U 12 ~ U 52 , its voltage value increases from the ion source terminal to the mass spectrometer injection interface terminal, that is, U 11 21 31 ,U 12 22 32 42 52 . There is a potential difference between the electrode pairs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com