Method for adsorbing H2S in coke oven gas

A technology of coke oven gas and coke oven, which is applied in the field of simultaneous partial regeneration of H2S in ion exchange fiber adsorption coke oven gas, which can solve the problems of affecting production safety, reducing process progress, and long construction period, so as to improve utilization rate and reduce operation Effects of cost and usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

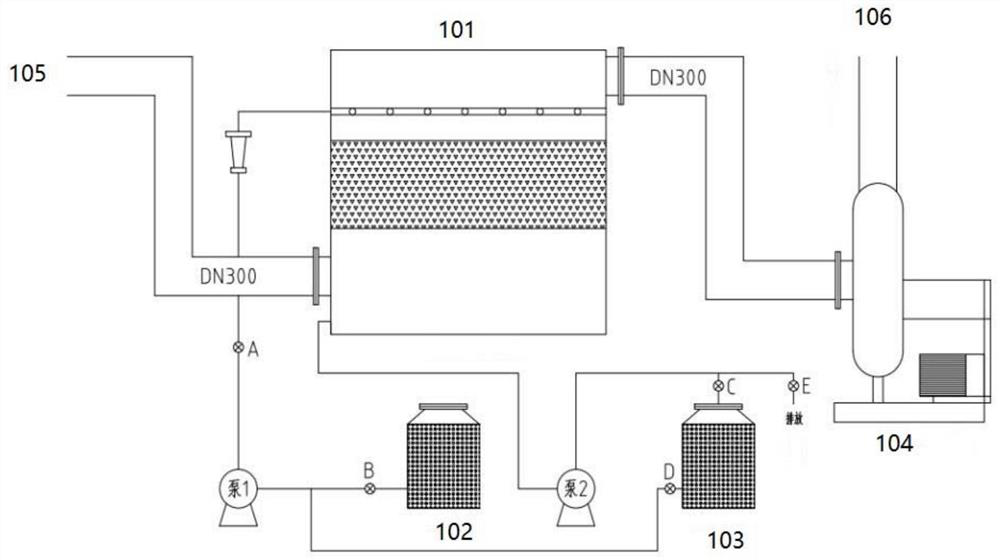

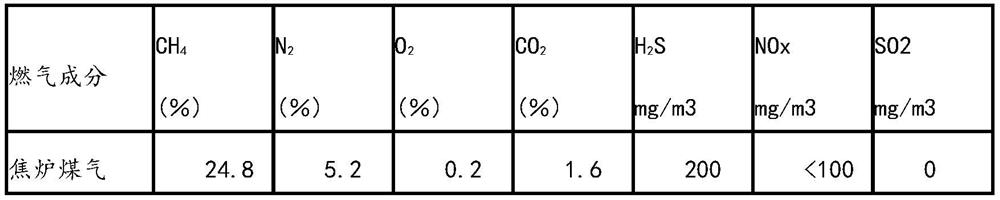

[0114] Taking the coke oven gas treatment unit of 4# furnace in Shaoer Power Station as an example, the 1080m 3 / h H in coke oven gas 2 S content is 163mg / m 3 :

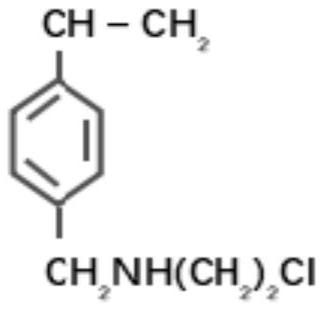

[0115] 1) Transformation: Using OH strong base anion exchange fiber 8.34m 3 , the ion exchange material is first transformed with 3% NaClO+5% NaOH (PH about 13) before use; during the transformation, control 1 times the space flow velocity, and the dosage is 2 times the volume of the ion exchange material;

[0116] 2) Operation: Turn on the induced draft fan to run normally, (during the operation period, do not stop the machine for spraying);

[0117] 3), running end control: when the processed H 2 S gas leakage exceeds 15mg / m 3 (or H 2 S test paper starts to change color) and starts to drip;

[0118] 4), Drenching liquid: 2.78m of oxidizing agent is prepared in the oxidizing agent storage tank 3 , open valves A and B, close valves D, C and E, start pump 1, and control the flow rate of oxidant to 4.17m 3 / h ...

Embodiment 2

[0122] The composition of spray oxidant solution is 4% Ca(ClO) 2 +4%NaOH, other steps are the same as in Example 1.

Embodiment 3

[0124] The spray oxidant solution consists of: 2% NaClO 2 +1%NaOH, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com