Strong hydrophilic microneedle base material, drug-loaded microneedle and application of drug-loaded microneedle in disease treatment

A microneedle and base material technology, applied in the field of microneedles, can solve the problems of complicated process, low drug utilization rate, and poor comprehensive benefit, and achieve the effects of simple process, guaranteed drug quality, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

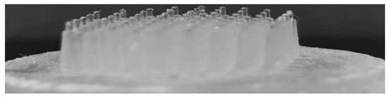

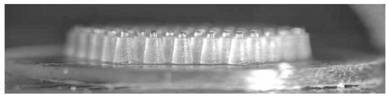

[0100] Further, the present invention provides a method for preparing a strongly hydrophilic blank microneedle, wherein the polyvinyl alcohol powder and the small molecule polyol powder are weighed according to the hydroxyl ratio (converted into a weight ratio) Perform blending at room temperature to form a blended powder, hot press the blended powder into a molding material, and hot press the molded material into a mold to form a blank microneedle; or use the blended powder at a certain temperature to Blending mechanical hot-mixing and melt-extruding into profiles, and hot-pressing the profiles into molds to form blank microneedles (see attached Figure 6 And attached Figure 7 : 700 is the whole blank microneedle, 701 is the blank microneedle body).

[0101] The mold used in an optimized embodiment of the present invention is on a flat plate with a thickness of 0.2 to 3 mm, with one or more groups of microhole arrays, and the microholes are through holes; the material of th...

Embodiment 1

[0121] Example 1: Testing and Control of Microneedle Composition Substrate Molding Temperature Range

[0122] According to the composition of the microneedle composition base material of the present invention: the ratio of the small molecule polyhydroxy compound to the polyvinyl alcohol is blended to obtain the blended powder, and on the microneedle preparation equipment of Example 2, in a certain pressure range (28- 32kg / cm 2 ), in order to obtain better prefabricated discs and / or microneedle molding, adjust the temperature to conduct experiments to obtain a lower limit temperature with better operability, and the results are organized as follows Figure 23 As shown in the table in the table, the table shows that at 28-32kg / cm 2 Under pressure conditions, the prefabricated disc and / or microneedle molding temperature of different hot extrusion materials, the proportion is the weight ratio, and the unit is w / w.

[0123] After adding small molecular polyols such as mannitol, s...

Embodiment 2

[0124] Embodiment 2: Preparation device and process method of prefabricated discs, blank microneedles and other material discs used for testing

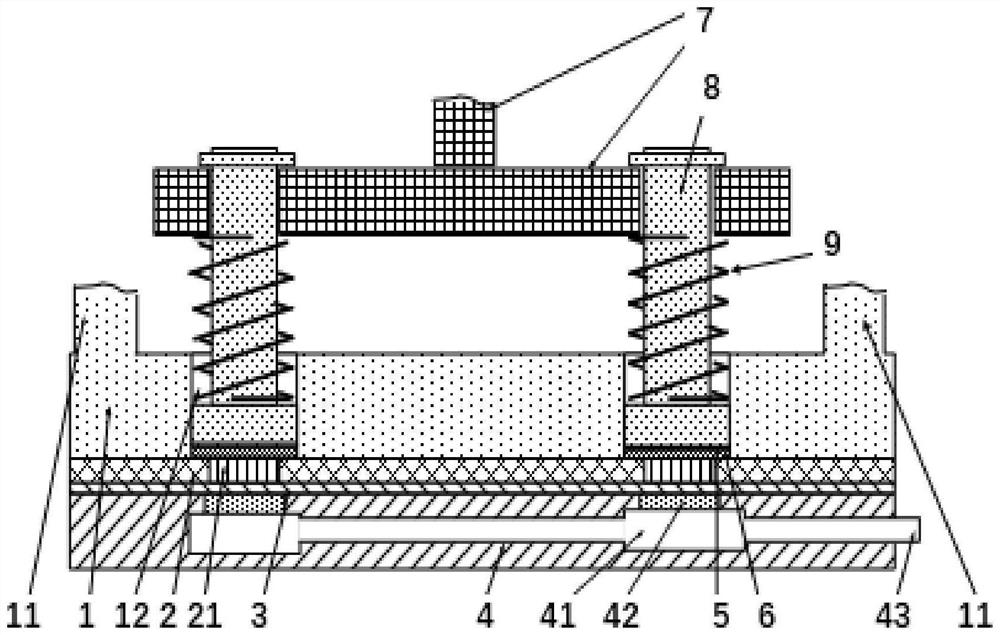

[0125] According to attached figure 1 Shown is a schematic diagram of an example of a microneedle preparation device used in the present invention. The test blank microneedle and the test sample disk of the present invention are all completed on the device.

[0126] Such as figure 1 As shown, the special microneedle preparation device includes, from top to bottom, an upper compression plate 1, a mold plate 2, an isolation layer 3, and an air extraction plate 4. The isolation layer 3 is made of a gas-permeable and liquid-impermeable material, and the mold plate 2 is provided with a microporous area 21 corresponding to the needle of the microneedle, the micropore is a through hole, and a cavity 41 is provided in the air pumping plate 4, and the corresponding microporous area 21 on the air pumping plate 4 The position is provided wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com