Soluble chitosan-PVP compound emulsifier as well as preparation method and application thereof

A chitosan and soluble technology, which is used in the application of emulsifiers and the preparation of soluble chitosan-PVP composite emulsifiers, can solve the problem of low stability of PVP emulsifiers and achieve stable properties and strong emulsifying ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

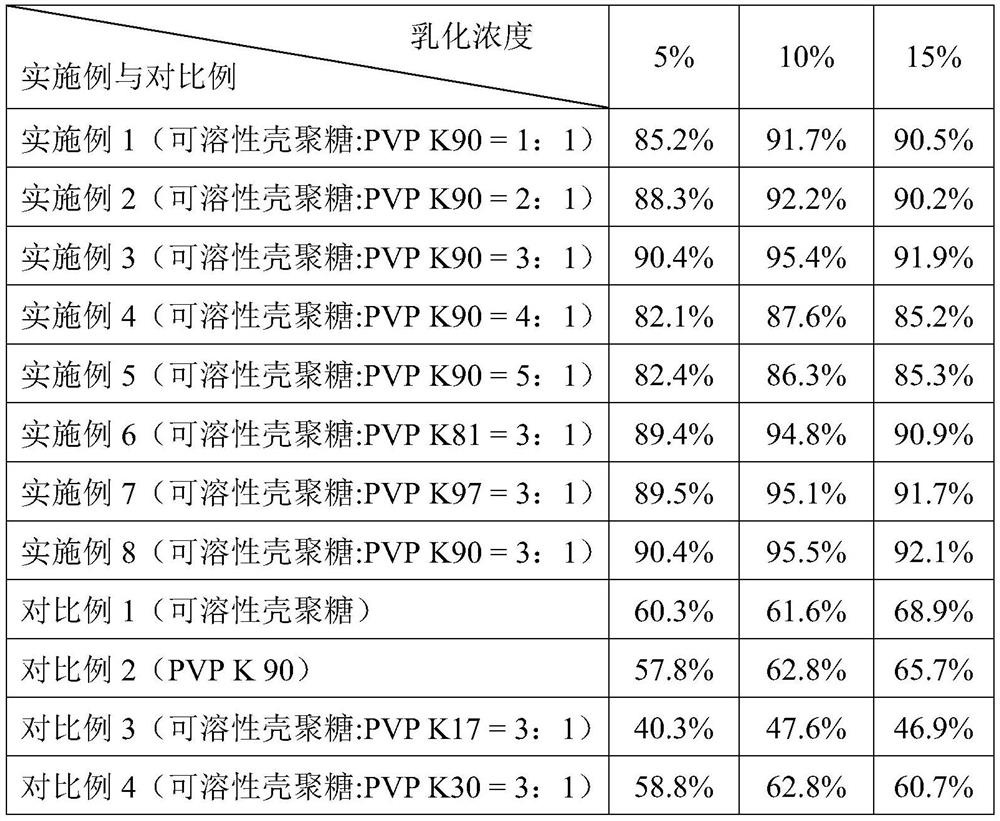

Embodiment 1

[0025] When soluble chitosan: PVP (K90) = 1:1 (mass ratio), mix 10g soluble chitosan (molecular weight 500), 10g PVP (K90) and dissolve in 100mL distilled water, heat in a water bath at 40°C , stirred for 1.5h, sealed and stored at 4°C for 3h, and vacuum freeze-dried the obtained soluble chitosan-PVP complex solution at -30°C for 24h to obtain 20g of a freeze-dried preparation of the soluble chitosan-PVP complex. Use 10mL of distilled water to prepare emulsifiers with mass fractions of 5%, 10%, and 15%, respectively.

Embodiment 2

[0027] When soluble chitosan:PVP(K90)=2:1 (mass ratio), mix 10g soluble chitosan (molecular weight 500), 5g PVP(K90) and dissolve in 100mL distilled water, heat in a water bath at 40 ℃, stirred for 1.5h, sealed at 4°C for 3h, and the soluble chitosan-PVP complex solution was vacuum freeze-dried at -30°C for 24h to obtain a freeze-dried preparation of 15 g of the soluble chitosan-PVP complex. The mass fractions prepared by using 10 mL of distilled water are respectively 5%, 10%, and 15% emulsifiers.

Embodiment 3

[0029] When soluble chitosan: PVP (K90) = 3:1 (mass ratio), mix 12g soluble chitosan (molecular weight 500), 4g PVP (K90) and dissolve in 100mL distilled water, heat in a water bath at 40°C , stirred for 1.5 h, sealed and stored at 4° C. for 3 h, and the soluble chitosan-PVP complex solution was vacuum freeze-dried at -30° C. for 24 h to obtain 16 g of a freeze-dried preparation of the soluble chitosan-PVP complex. The mass fractions prepared by using 10 mL of distilled water are respectively 5%, 10%, and 15% emulsifiers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com