Dust-free automatic discharging device for graphite crucibles

An automatic discharge device and graphite crucible technology, which is applied in the direction of swirl devices, packaging, solid materials, etc., can solve the problems of taking out materials that are difficult to agglomerate, low vacuum suction efficiency, technical troubles, etc., and achieve increased productivity. , saving resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

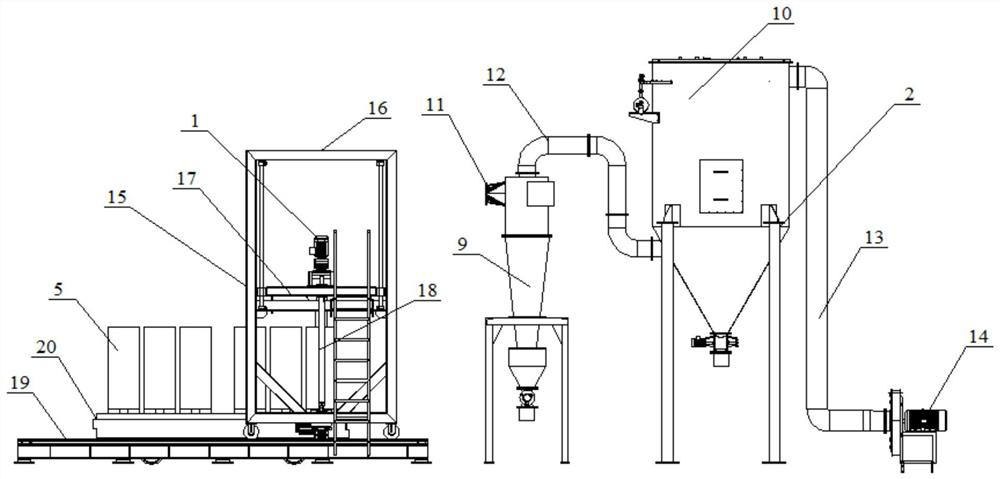

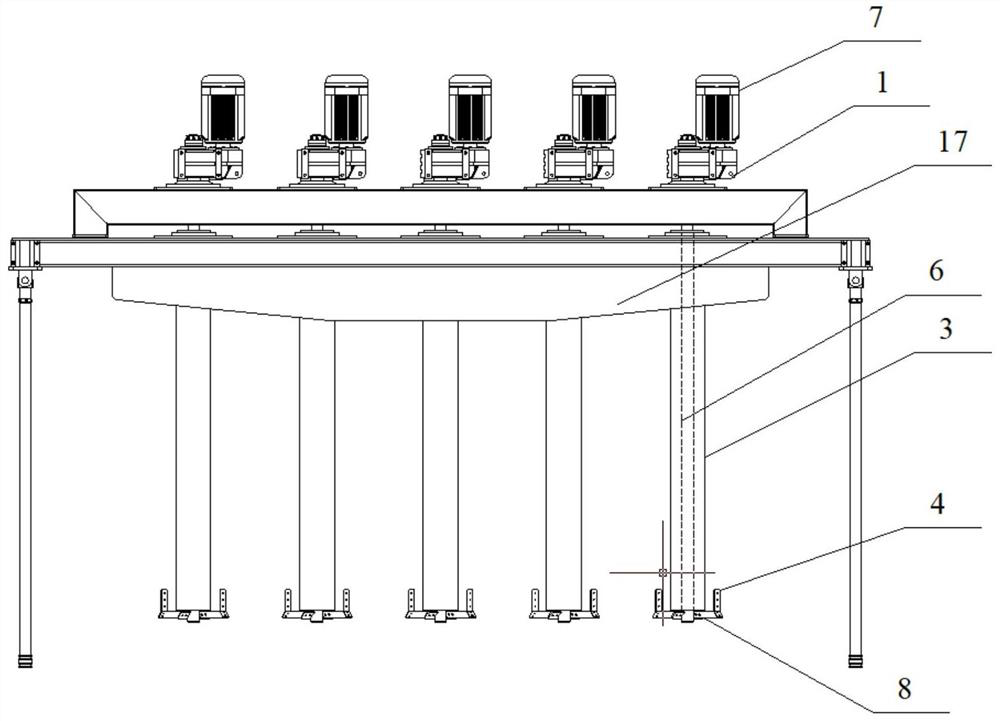

[0029] A graphite crucible dust-free automatic discharging device, comprising a working platform 15 and a collection filter mechanism 2, the working platform 15 includes an upper frame 16 and a lifting platform 17, the lifting platform 17 is provided with a material suction and crushing mechanism 1, and the lifting The platform 17 can move up and down on the frame 16, wherein the lifting platform 17 is driven by two oppositely arranged lifting oil pressure rods 18 to move up and down; the bottom of the frame 16 is provided with a driving track 19, a driving rack and a driving control system, the driving rack is arranged on the driving track 19.

[0030] This embodiment is used to suck out the bulk graphite in the crucible after firing, wherein the crucible kiln car mechanism 20 with the crucible 5 is movable, and the crucibles 5 are arranged in an array on the crucible kiln car mechanism 20, with 4 in each row, 5, 6 or more.

[0031] When in use, move the crucible kiln car me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com