Adsorbent, method for preparing aluminum hydroxide and application

A technology for the reaction of aluminum hydroxide and aluminum water, applied in chemical instruments and methods, preparation of alumina/hydroxide, reagents, etc., can solve the problems of single particle size and difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

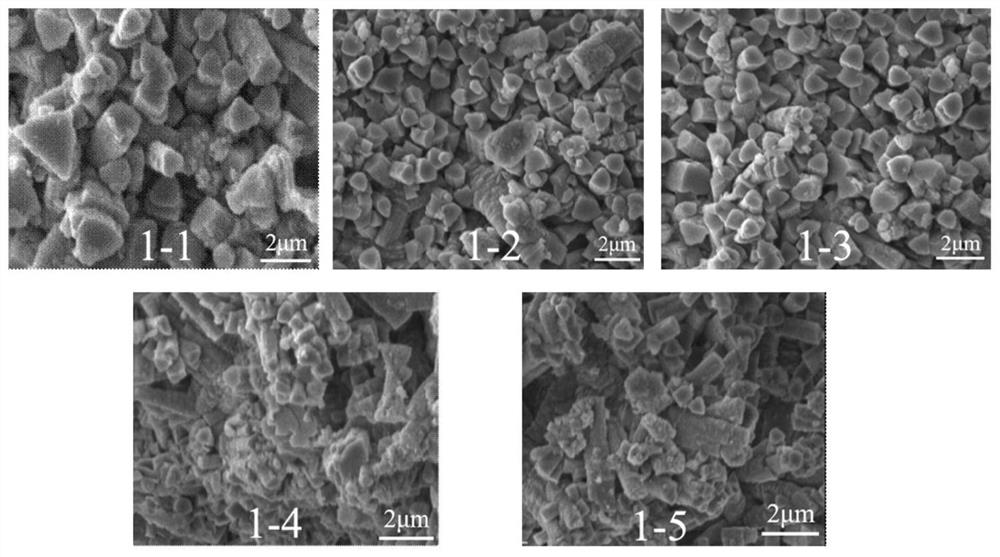

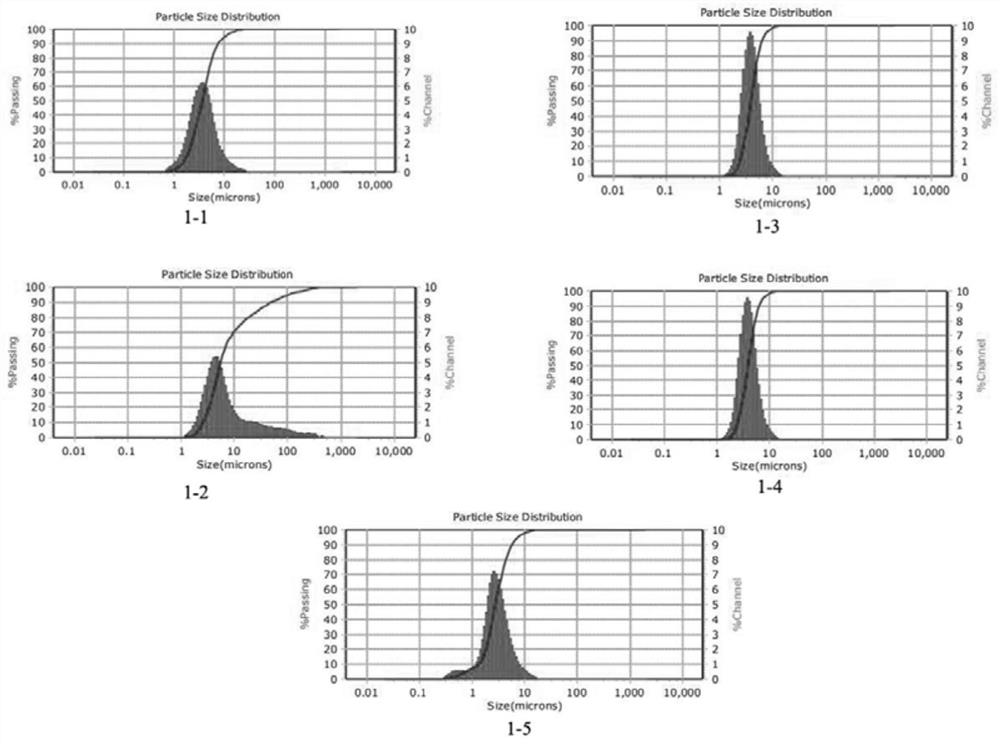

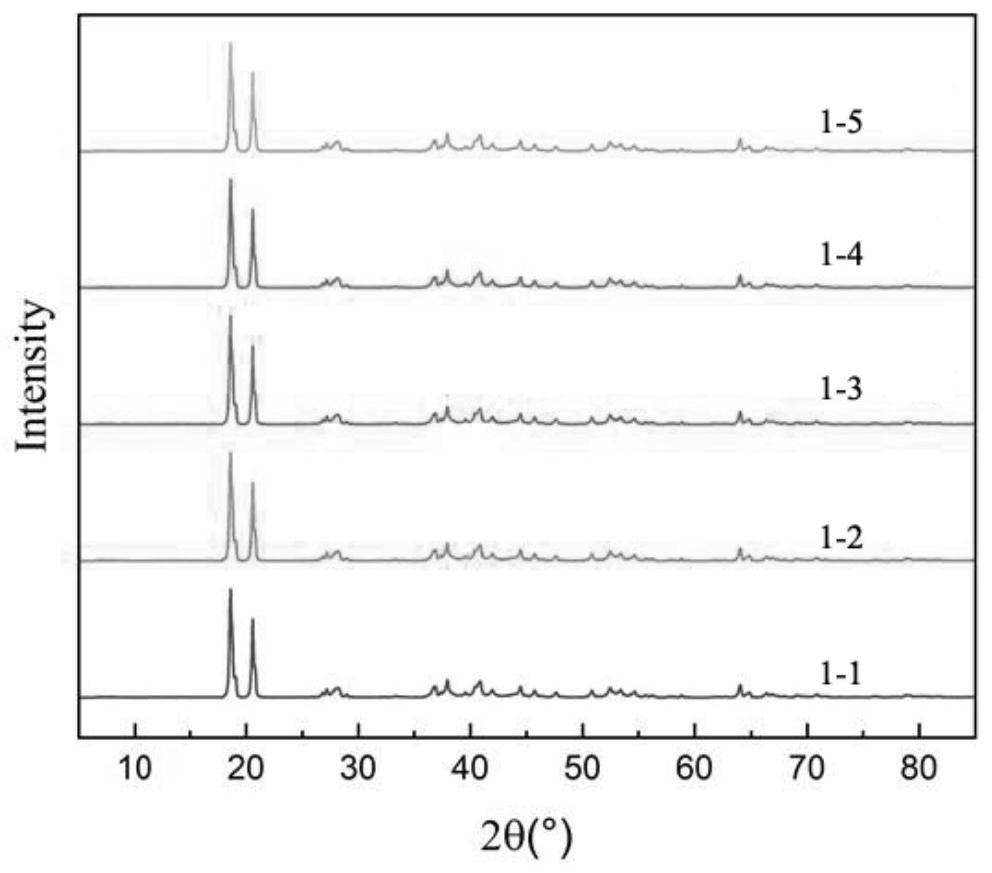

[0074] Inject water into the reaction kettle with the stirrer started and heated to the set temperature, and then add the catalyst for thorough mixing to form a solution. Then aluminum elemental substance is added therein and continuously stirred for reaction. After the reaction was completed, the filtrate was removed by filtration, and the obtained precipitate was dried at a set drying temperature under vacuum conditions. Wherein, the aluminum element is aluminum foil, the purity is 4N, and the added mass is 10 g. The liquid-solid ratio between the volume of the catalyst and the mass of aluminum is 5:1 (g / L). The stirring speed is 800r / min, the reaction temperature is 80°C, the reaction time is 4h, the drying temperature is 80°C, and the drying time is 24h. The amount of alkylammonium hydroxide added is 1% of the total solution volume.

[0075] The other embodiments are carried out according to the process of Example 1-1, and the main difference lies in the composition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com