Refining method of adiponitrile

A refining method and adiponitrile technology, applied in the direction of carboxylic acid nitrile purification/separation, organic chemistry, etc., can solve the problems of low product quality of adiponitrile, introduction of new impurities, poor effect, etc., to meet the quality requirements, No need for heating, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

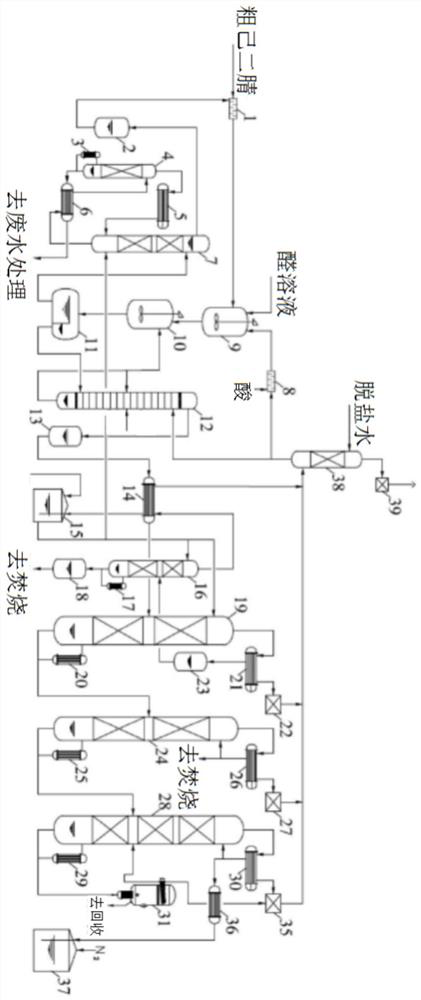

[0072] The present embodiment provides a kind of refining device of adiponitrile, such as figure 1 shown, including:

[0073] The extract liquid mixer 1 includes a crude adiponitrile inlet, an extract liquid inlet, and an organic mixed liquid outlet. The outlet of the organic mixed liquid is communicated with the inlet of the organic mixed liquid of the ICCP hydrolysis reactor 9.

[0074] The dilute acid mixer 8 includes a desalted water inlet, a concentrated acid solution inlet, and a dilute acid aqueous solution outlet. The outlet of the dilute acid aqueous solution communicates with the inlet of the dilute acid aqueous solution of the ICCP hydrolysis reactor 9.

[0075] The ICCP hydrolysis reactor 9 comprises a stirring mixer, an aldehyde aqueous solution inlet, a dilute acid aqueous solution inlet, an organic mixed solution inlet, and a hydrolysis reaction liquid outlet; The organic mixed solution is evenly mixed to promote the rapid hydrolysis of ICCP to generate 2-cya...

Embodiment 2

[0115] The present embodiment provides a kind of refining method of adiponitrile, adopts figure 1 Shown adiponitrile refining system specifically comprises the steps:

[0116] The crude adiponitrile in this embodiment is the crude adiponitrile solution obtained after the reaction mixture obtained by the reaction of adipic acid and ammonia is separated and washed with ammonia water, and its composition is: adiponitrile 88.48% (wt), ICCP0.41 %(wt), 5-cyanovaleramide 1.60% (wt), 5-cyanovaleric acid 0.06wt%, adipamide 0.12wt%, ammonia 0.45wt%, water 8.59wt%, cyclopentanone 0.29 % (wt).

[0117] (1) Hydrolysis and washing separation of ICCP

[0118] The thick adiponitrile solution of 100kg / h and the toluene extraction solution 103.66kg / h sent through the extract storage tank 2 are mixed uniformly in the extract mixer 1 and then enter the ICCP hydrolysis reactor 9, and react in the ICCP hydrolysis reaction Add 5.0kg / h of 35% formaldehyde solution into vessel 9, then add 13.10kg / h...

Embodiment 3

[0135] The present embodiment provides a kind of refining method of adiponitrile, adopts figure 1 Shown adiponitrile refining system specifically comprises the steps:

[0136] The crude adiponitrile in this embodiment is the crude adiponitrile solution obtained after the reaction mixture obtained by the reaction of adipic acid and ammonia after separation and washing with ammonia water, and its composition is: adiponitrile 89.68% (wt), ICCP0.42 % (wt), 5-cyanovaleramide 1.39% (wt), 5-cyanovaleric acid 0.09% (wt), adipamide 0.09% (wt), ammonia 0.36% (wt), water 7.75% (wt), cyclopentanone 0.22% (wt).

[0137] (1) Hydrolysis and washing separation of ICCP

[0138] The thick adiponitrile solution of 100kg / h and the toluene extraction solution 153.29kg / h sent through the extract storage tank 2 are mixed uniformly in the extract mixer 1 and enter the ICCP hydrolysis reactor 9, and in the conversion reactor 9 Add 35% formaldehyde solution 2.0kg / h to the solution, then add 10% (wt)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com