Low-density water-based workshop primer and preparation method thereof

A shop primer and low-density technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of high coating density and unfavorable construction, reduce zinc fog and weld pores, and have excellent anti-corrosion performance , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a low-density water-based shop primer, comprising the preparation of component A and component B, and the specific preparation steps are as follows:

[0035] The preparation method of described A component is:

[0036] (1) adding aqueous silicate solution and aqueous graphene slurry to the reaction vessel and stirring;

[0037] Wherein, the stirring speed is preferably 500-800 rpm, and the stirring time is preferably 10-20 min;

[0038] (2) Packaging to obtain the finished product.

[0039] Wherein, the mass fraction added to the aqueous silicate solution is preferably 55-80 parts, more preferably 70-80 parts; the mass fraction added to the aqueous graphene slurry is preferably 20-45 parts, more preferably 20 to 30 servings.

[0040] The preparation method of described B component is:

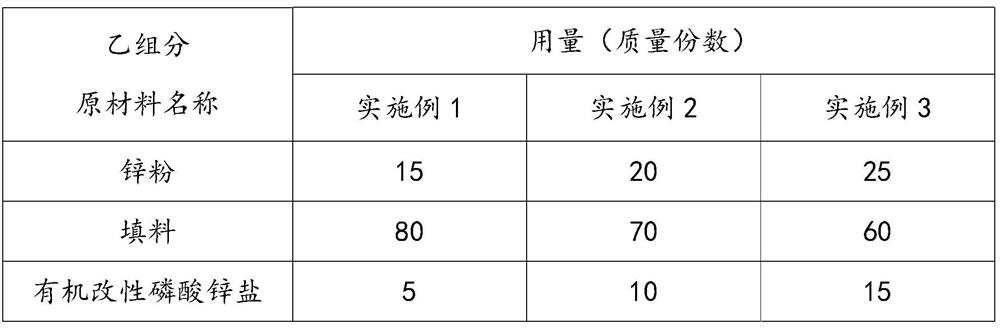

[0041] (1) Add zinc powder, filler and organically modified zinc phosphate into a preparation container for mixing, sieve and package to...

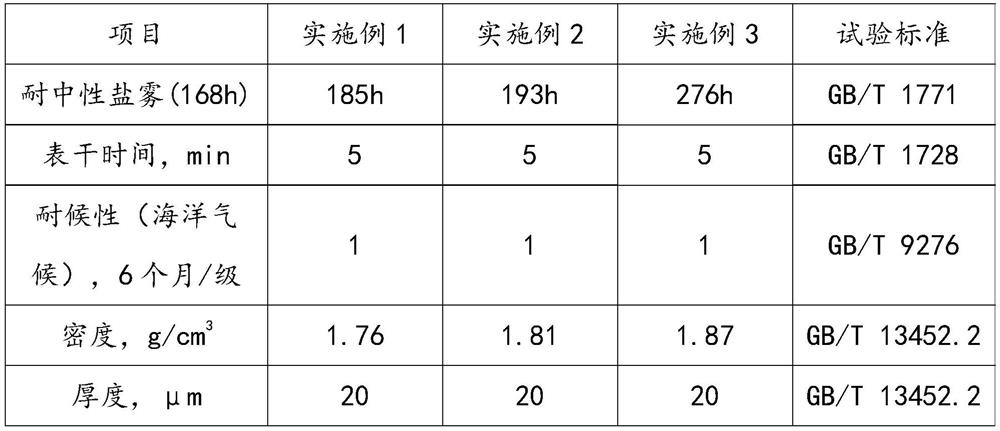

Embodiment 1

[0047] For Example 1, in its component A raw material: the aqueous silicate solution is a potassium silicate solution; the aqueous graphene slurry adopts the aqueous graphene slurry of GRF-HCGW-01, wherein the graphene slurry The mass solid content of the material is 8%;

[0048] The stirring speed is 500-700rpm, and the stirring time is 10min; among the raw materials of component B, the zinc powder is spherical zinc powder with a fineness of 800 mesh; the filler is talcum powder, wollastonite powder, and ferrophosphorus powder; The organic modified zinc phosphate salt adopts 702 organic modified zinc phosphate salt.

Embodiment 2

[0049] For Example 2, in its component A raw material: the aqueous silicate solution is a potassium silicate solution; the aqueous graphene slurry adopts the aqueous graphene slurry of GRF-HCGW-01, wherein the graphene slurry The mass solid content of the material is 10%;

[0050] The stirring speed is 500-700rpm, and the stirring time is 10min;

[0051] Among the raw materials of component B, the zinc powder is spherical zinc powder with a fineness of 800 mesh; the filler is talcum powder, wollastonite powder, and ferrophosphorus powder; the organic modified zinc phosphate is 702 organically modified Zinc phosphate salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com