Monatomic nickel-nitrogen coordination co-doped porous carbon/nano-zirconia composite electrode as well as preparation method and application thereof

A nano-zirconia, composite electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of weak adsorption capacity, slow conversion rate, weak adsorption capacity, etc., and achieve easy operation, excellent electrocatalytic activity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

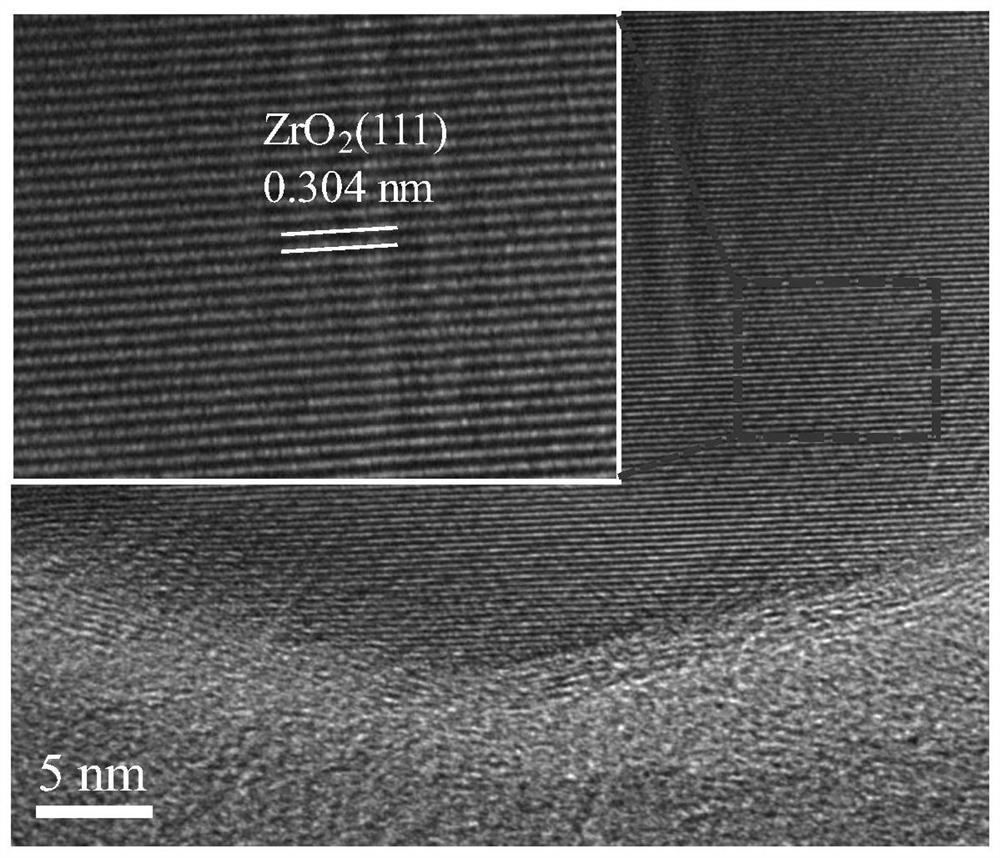

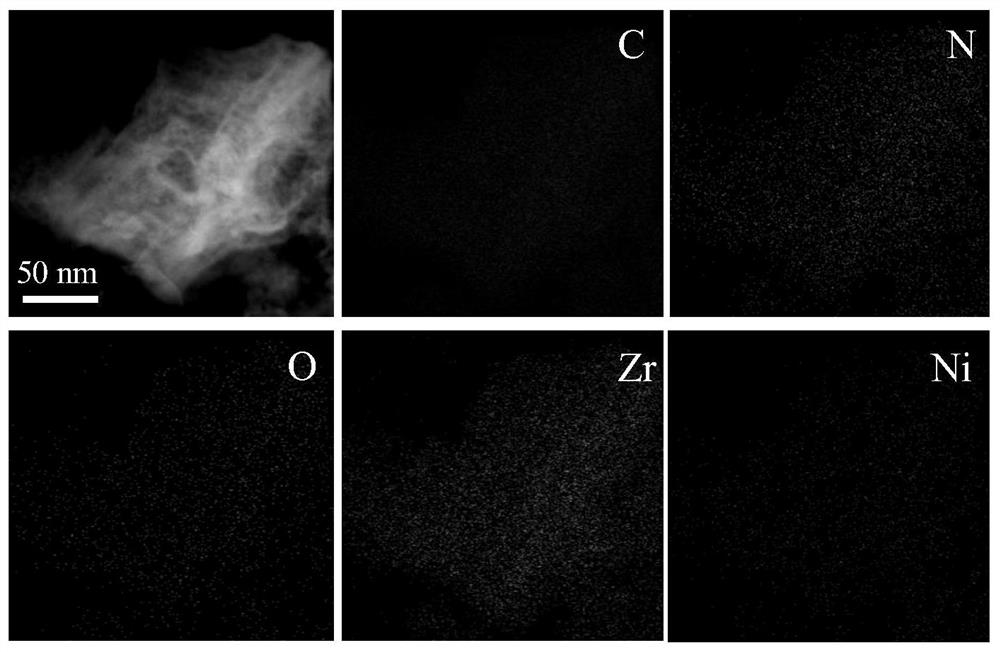

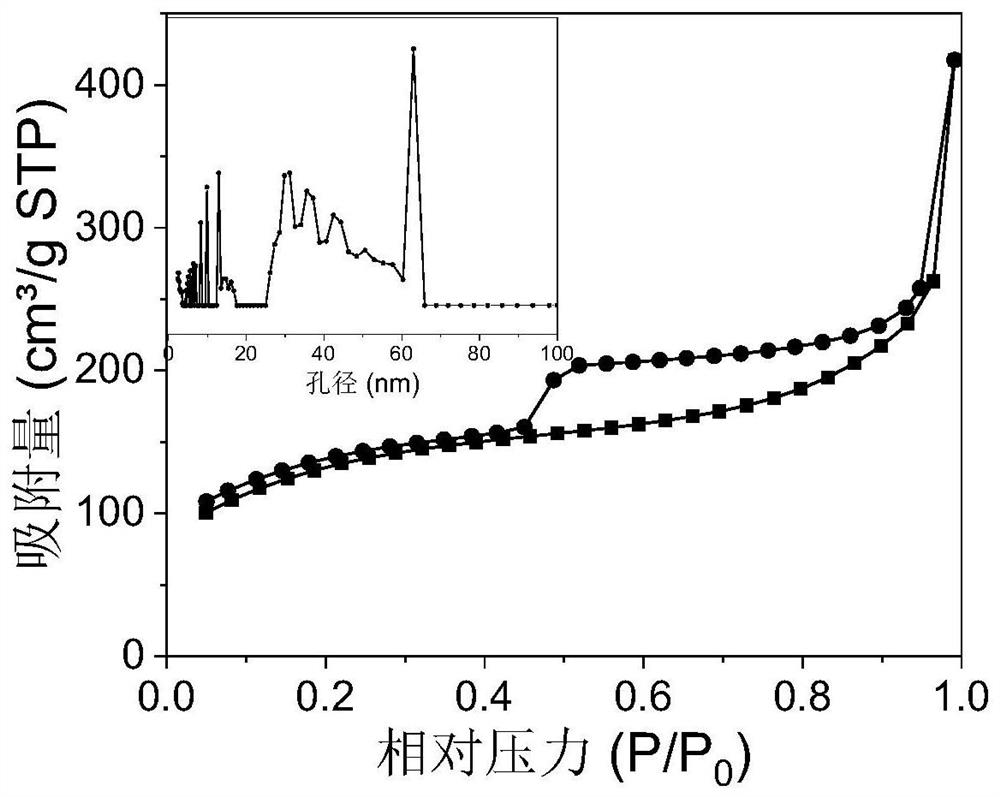

Embodiment 1

[0049] Step (1): Add 122.5mg of zirconium chloride, 130mg of 2,2-bipyridine-5,5-dicarboxylic acid and 3mL of formic acid into 50mL of N,N-dimethylformamide, stir magnetically for 10min until the mixture is uniform , hydrothermally reacted at 120°C for 24 hours, after the mixture was cooled to room temperature, centrifuged at a high speed of 10,000r / min, the filter cake was washed with N,N-dimethylformamide and acetone for 3 times, and finally the filter cake Dry in a vacuum oven at 90°C for 10 hours to obtain MOFs materials;

[0050] Step (2): Take 0.56 g of the MOFs material obtained in step (1), and add 133.1 mg of nickel chloride into 150 mL of acetonitrile, mix and stir for 24 h at room temperature at 25 ° C, then perform centrifugal washing, and wash the filter cake with acetonitrile 3 times, and finally dry the filter cake in a vacuum oven at 80°C for 12 hours to obtain a metal-organic framework in which metal nickel ions are coordinated with the nitrogen species of 2,2-...

Embodiment 2~4

[0056] As in the preparation method of Example 1, only the calcination temperature in step (3) was changed to 700°C, 800°C and 1000°C to obtain nickel-nitrogen coordination co-doped porous carbon / nano-zirconia composite electrodes at different calcination temperatures .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com