Terahertz wave modulator based on magnetic tunnel junction and preparation method of terahertz wave modulator

A magnetic tunnel junction and modulator technology, which is applied in the fields of magnetic field controlled resistors, the manufacture/processing of electromagnetic devices, material selection, etc., can solve the problems of narrow modulation spectrum, difficult to meet requirements, and small depth, etc. The effect of wide range, high modulation depth and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

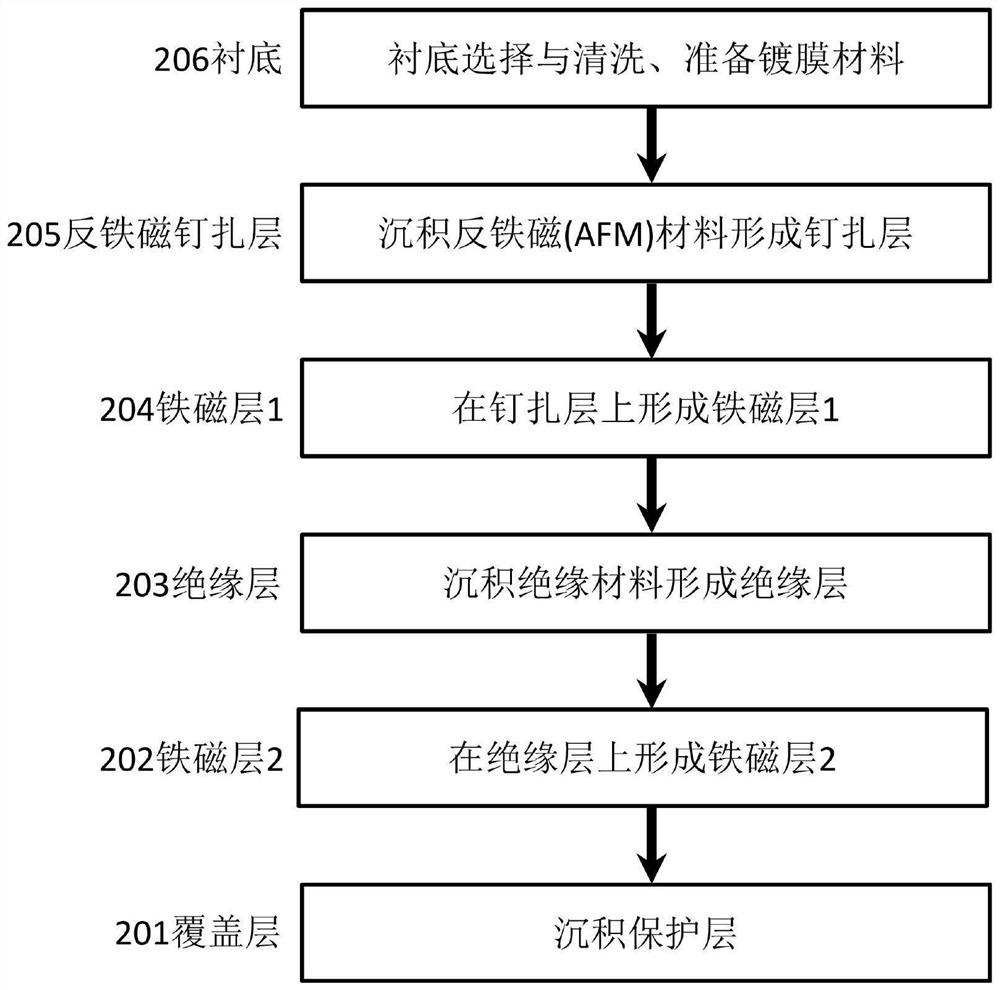

[0040] A preparation method of a terahertz wave modulator based on a magnetic tunnel junction, using physical or chemical coating methods, successively coating a multi-layer magnetic metal film and a non-magnetic metal film on a substrate to form a composite film structure; an external small An electromagnet; by controlling the current, the regulation of the amplitude of the terahertz radiation is realized, including the following steps:

[0041] S206, selecting and cleaning the substrate, and preparing materials for coating;

[0042] S205, depositing an antimagnetic material on the substrate to form an antiferromagnetic pinning layer 105;

[0043] S204, forming a first ferromagnetic layer 104 on the antiferromagnetic pinning layer 105 above S205;

[0044] S203, depositing an insulating material on the first ferromagnetic layer 104 in step S204 to form an insulating layer 103;

[0045] S202, forming a second ferromagnetic layer 102 on the insulating layer 103 in step S203;

...

Embodiment 1

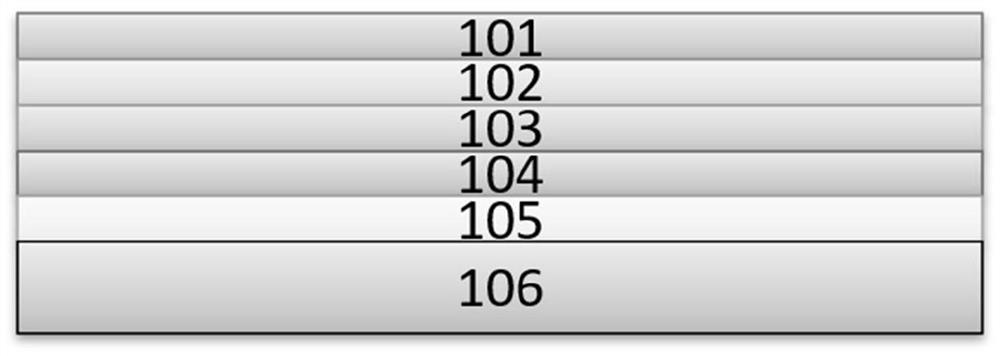

[0049] see Figure 1~2 , the terahertz wave emitter is composed of a substrate substrate and a magnetic tunnel junction plated on the substrate. From the substrate to the top: 105 antiferromagnetic pinning layer (IrMn-10nm), 104 ferromagnetic layer (CoFeB-3nm), 103 insulating layer (MgO-1.9nm), 102 ferromagnetic layer (CoFeB-3nm) , 101 cover layer (Ta-5nm). Wherein the ferromagnetic layer has an in-plane magnetization direction. The given thickness is a commonly used thickness, and changing different thicknesses can greatly change the background transmittance of terahertz waves. In addition, buffer layers are often used to fill between layers to improve performance. Ru is commonly used, with a thickness of less than 1nm. Use commonly used physical and chemical coating methods, such as magnetron sputtering, chemical vapor deposition, molecular beam epitaxy, etc.

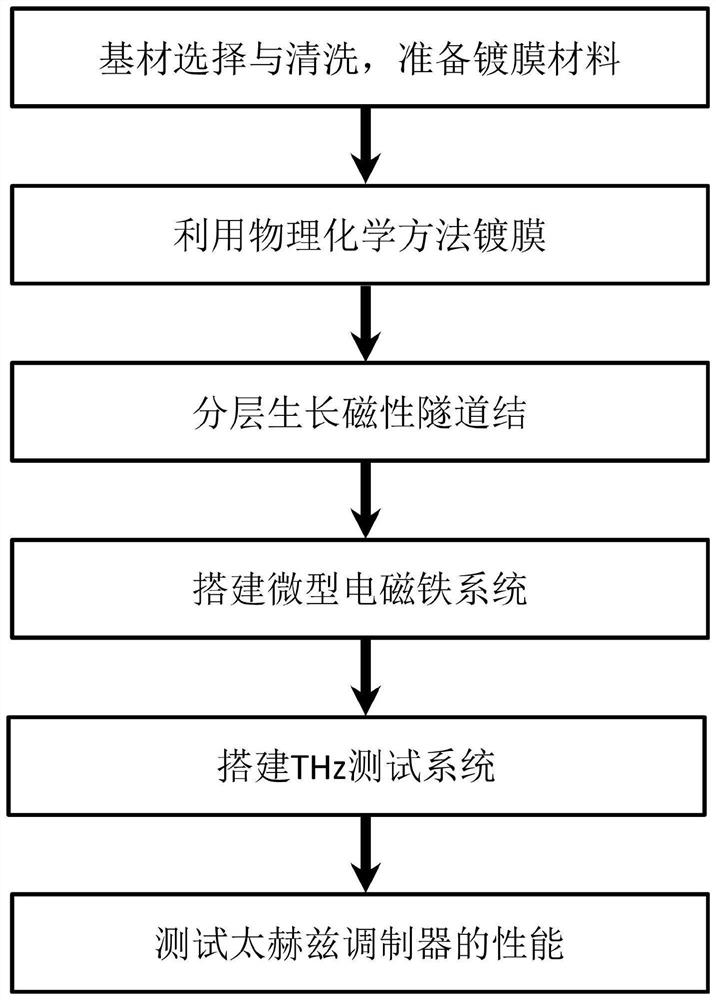

[0050] image 3 The overall test scheme of the terahertz modulator is given.

[0051] Figure 4 It is a sche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com