Lithium ion battery pole piece preparation method

A lithium-ion battery and pole piece technology, which is applied in the field of lithium-ion battery pole piece preparation, can solve the problems of low actual utilization of current collectors, achieve the effects of reducing viscosity, avoiding excessive area, and optimizing the structure of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

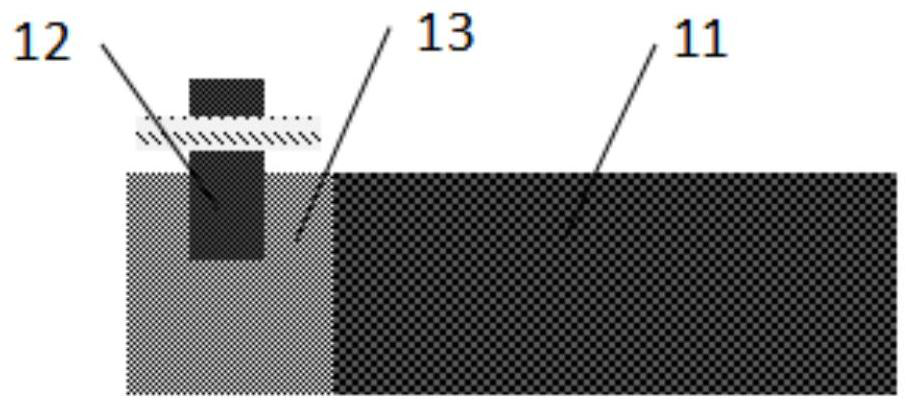

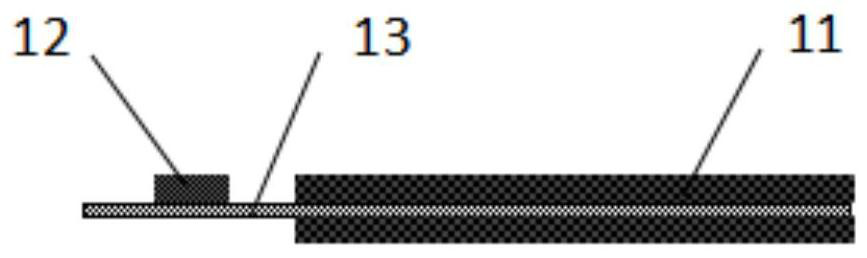

[0030] The embodiment of the present invention provides a lithium ion battery pole piece preparation method, comprising the following steps:

[0031] 1) Provide a current collector, and paste heat-shrinkable glue on the tab position of the current collector. The heat-shrinkable glue includes a base material and an adhesive layer, and the base material is pasted on the collector through the adhesive layer. The surface of the fluid, the base material is a heat-shrinkable film, and the adhesive layer includes acrylic resin and sugar compound;

[0032] 2) Coating the active material slurry on the surface of the current collector and the heat shrinkable rubber to obtain the active material membrane;

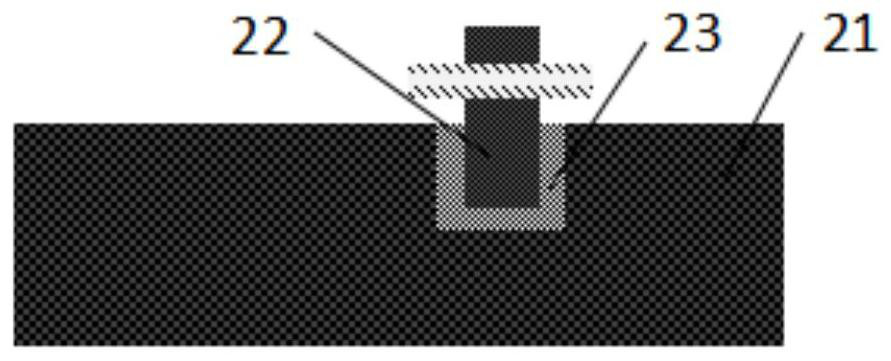

[0033] 3) The active material diaphragm is dried at the heat shrinkage temperature of the heat shrinkable rubber. The heat shrinkable rubber on the diaphragm shrinks and falls off from the surface of the current collector, and the active material on the heat shrinkable rubber is separ...

Embodiment 1

[0055] This embodiment is used to illustrate the lithium ion battery pole piece preparation method disclosed in the present invention, comprising the following steps:

[0056] 1) Lead the current collector foil to the feeding mechanism of the coating machine, through the traction mechanism, the foil moves forward at a certain speed, calculate the moving distance of the foil through the encoder, and the automatic labeling machine according to the encoder and sensor Paste heat-shrinkable adhesives with a length of 25mm, a width of 10mm, and a thickness of 20um on the designated position of the current collector, wherein one or more heat-shrinkable adhesives can be pasted at the designated position of the current collector; the heat-shrinkable adhesive includes the base material and an adhesive layer, the base material is pasted on the surface of the current collector through the adhesive layer; the base material is a PVC heat-shrinkable film; the adhesive layer includes 50% acryl...

Embodiment 2

[0060] This example is used to illustrate the lithium ion battery pole piece preparation method disclosed in the present invention, including most of the operating steps in Example 1, the difference is that: the adhesive layer includes 70% acrylic resin and 10% Fructose, 20% sucrose, all the other operations are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com