Miniaturized filter

A filter and cavity technology, which is applied in the field of filters, can solve the problems of large size, many types of materials, and heavy weight of the filter, and achieve the effect of simple welding process, few types of materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

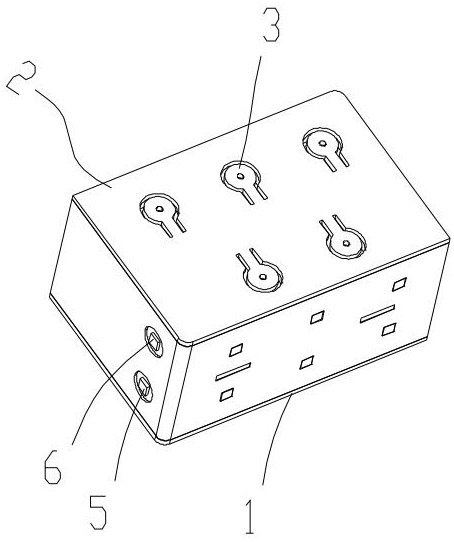

[0028] A miniaturized filter such as figure 1 and figure 2 As shown, it includes a cavity 1 made of metal material, the top and bottom of the cavity are covered with a debugging cover 2, a plurality of coupling tuning elements 3 are arranged on the debugging cover, and an integrated The integrated resonant piece 4 is formed by bending a single resonant piece or splicing a plurality of resonant pieces. One end of the integrated resonant piece is bent in a direction close to the other end, and its two ends have respectively The input port 5 and the output port 6 are arranged through the cavity 1 and both are arranged on the same end surface of the cavity. Therefore, the input and output of the transmission signal can be realized on the same plane, and the signal transmission structure becomes simpler.

[0029] Both the input port 5 and the output port 6 are boss-shaped structures 8, and the connection between the two boss-shaped structures and the cavity is provided with a su...

Embodiment 2

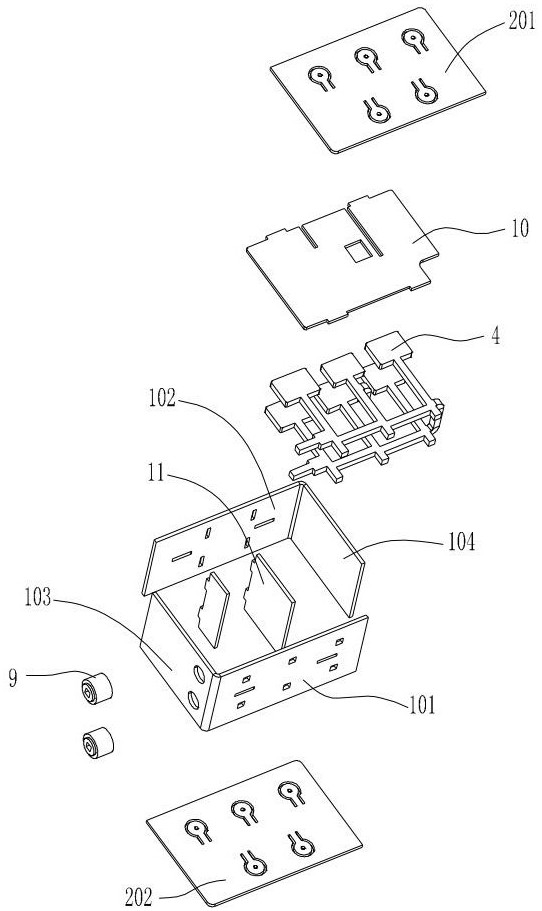

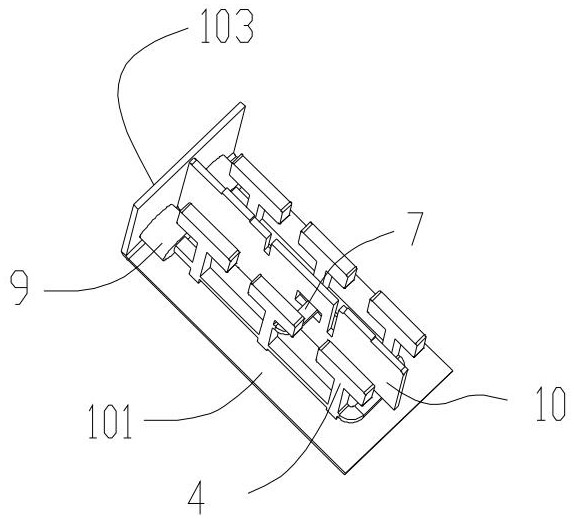

[0032] Such as image 3 and Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the inside of the cavity is also provided with at least one partition 10 arranged in the horizontal direction, and the partition 10 divides the inside of the cavity into a multi-layer structure, and is integrated The chemical resonance plate is located in one layer of the structure. Further, several clamping blocks are integrally arranged at the peripheral edge of the partition 10, bayonets corresponding to the several clamping blocks are provided on the side wall of the cavity, and the partition is set by the clamping blocks. In the bayonet, the partition 10 and the cavity 1 are connected by welding. Through the setting of the partition plate 10, the filter is separated into a multi-layer structure, so that the signal transmission channel can be realized more flexibly.

[0033] The side wall of the cavity 1 is also provided with a plurality of supporting medium p...

Embodiment 3

[0035] The difference between this embodiment and Embodiment 2 is that the bending angle of one end of the integrated resonant piece 4 is 180°, and the input port 5 and the output port 6 are arranged symmetrically. When the bending angle of one end of the integrated resonant piece 4 is At 180°, the input port and the output port are distributed up and down, as a preferred embodiment of the present invention, such as figure 2 As shown in , the input port 5 is located directly above the output port 6. The signal input and output end faces of the filter can be directly bonded and welded to the surface of the next device, or a connector can be used to transfer the signal input and output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com