MEMS inertial sensor chip module and preparation method thereof

An inertial sensor and chip module technology, applied in instruments, electric solid state devices, semiconductor devices, etc., can solve the problems of volume contradiction, complex overall process, increase in chip volume, etc., to reduce packaging and integration costs, reduce integration volume, Improve the effect of app restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

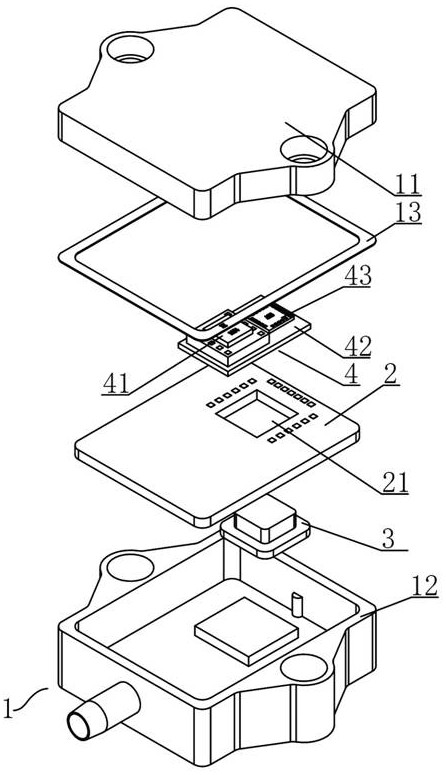

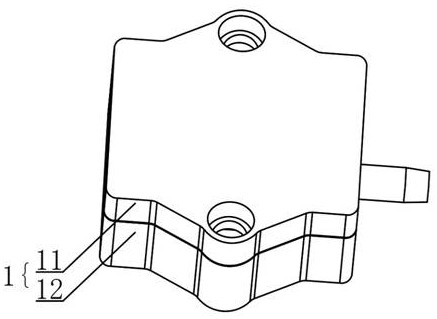

[0036] Such as figure 1 , figure 2 with image 3 As shown, the MEMS inertial sensor chip module of the present embodiment includes a housing 1, and the housing 1 is respectively fixed with a PCB board 2 and a metal support column 3, and the metal support column 3 is supported with a MEMS inertial sensor chip assembly 4, and the MEMS inertial sensor The connecting terminals on the chip component 4 are connected to the connecting terminals on the PCB 2 through metal wires.

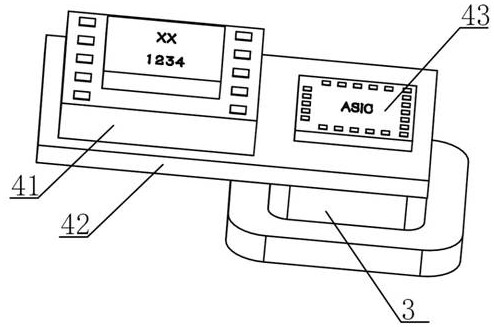

[0037] Such as figure 1 , figure 2 with Figure 4 As shown, in this embodiment, the MEMS inertial sensor chip assembly 4 includes a MEMS inertial sensor chip 41 and a substrate 42 with the same thermal expansion coefficient as the MEMS inertial sensor chip 41, the MEMS inertial sensor chip 41 is fixed on the substrate 42, and the substrate 42 supports and fixes On the end face of the metal support column 3.

[0038] It should be noted that, the MEMS inertial sensor chip assembly 4 can adopt a monocry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com