Quantitative filter paper and preparation method thereof

A technology for quantitative filter paper and parts by weight, which is applied in the direction of filter paper, separation methods, chemical instruments and methods, etc., and can solve the problems of inability to meet the requirements of filter paper, poor strength and toughness of filter paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

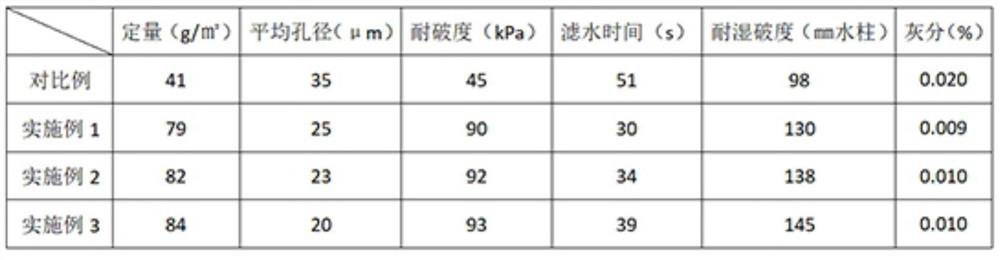

Embodiment 1

[0027] A quantitative filter paper, obtained in parts by weight: 40 parts of alkali-treated cotton linter pulp; 30 parts of hardwood pulp; 20 parts of mixed plant fiber; wherein the mixed plant fiber includes 5 parts of mulberry fiber; 5 parts 5 parts of green sandalwood fiber; 5 parts of ramie fiber; 5 parts of aloe cotton fiber.

[0028] Follow the steps below to prepare targeted rapid qualitative filter paper:

[0029] a) The alkali-treated cotton linter pulp is deflagged with a fiber deflagging machine, and at the same time, 1 part of vinyl bisstearamide and 1 part of polyamide polyepichlorohydrin resin are added, and then polished online by a double-disc refiner to obtain Pulp slurry with a pulping degree of 16-18°SR;

[0030] b) Defiber the hardwood pulp and mixed plant fibers with a fiber defiberizer, add 1 part of vinyl bis stearamide and 1 part of polyamide polyepichlorohydrin resin at the same time, and then grind on-line with a double disc refiner to obtain pulp P...

Embodiment 2

[0034] A quantitative filter paper, obtained in parts by weight: 60 parts of alkali-treated cotton linter pulp; 40 parts of hardwood pulp; 32 parts of mixed plant fibers; wherein the mixed plant fibers include 8 parts of mulberry fibers; 8 parts 8 parts of green sandalwood fiber; 8 parts of ramie fiber; 8 parts of aloe cotton fiber.

[0035] Follow the steps below to prepare targeted rapid qualitative filter paper:

[0036] a) The alkali-treated cotton linter pulp is defiberized with a defiberizing machine, and 1.2 parts of vinyl bisstearamide and 1.2 parts of polyamide polyepichlorohydrin resin are added at the same time, and then polished online by a double-disc refiner. Pulp slurry with a pulping degree of 16-18°SR;

[0037] b) Defiber the hardwood pulp and mixed plant fibers with a fiber defiberizer, add 1.2 parts of vinyl bis stearamide and 1.2 parts of polyamide polyepichlorohydrin resin at the same time, and then grind on-line with a double disc refiner to obtain pulp ...

Embodiment 3

[0041] A quantitative filter paper, obtained in parts by weight: 80 parts of alkali-treated cotton linter pulp; 50 parts of hardwood pulp; 32 parts of mixed plant fibers; wherein the mixed plant fibers include 8 parts of mulberry fibers; 8 parts 8 parts of green sandalwood fiber; 8 parts of ramie fiber; 8 parts of aloe cotton fiber.

[0042] Follow the steps below to prepare targeted rapid qualitative filter paper:

[0043] a) The alkali-treated cotton linter pulp is defiberized with a defiberizing machine, and 1.2 parts of vinyl bisstearamide and 1.2 parts of polyamide polyepichlorohydrin resin are added at the same time, and then polished online by a double-disc refiner. Pulp slurry with a pulping degree of 16-18°SR;

[0044] b) Defiber the hardwood pulp and mixed plant fibers with a fiber defiberizer, add 1.2 parts of vinyl bis stearamide and 1.2 parts of polyamide polyepichlorohydrin resin at the same time, and then grind on-line with a double disc refiner to obtain pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com