Device and method for simultaneously detecting SO2 and SO3 in flue gas

A flue gas and flue gas pipe technology is applied in the field of devices that simultaneously detect SO2 and SO3 in flue gas. Avoid the interference of reducing gas, overcome randomness, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

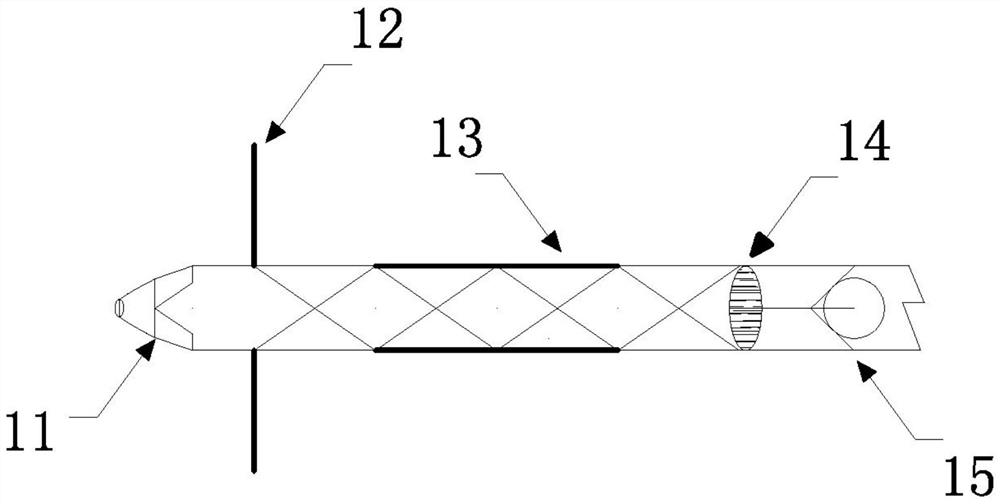

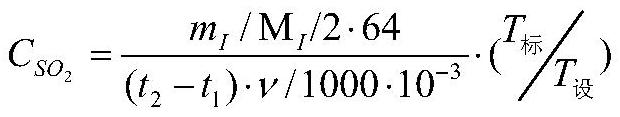

[0060] A catalytic regeneration flue gas temperature is 500 ℃. Before sampling, it is necessary to select a suitable sampling point on the flue gas pipeline, and set a sampling port with a diameter of DN40 at the sampling point, insert the standard gas sampling probe into the flue, and connect it with a flange to collect the flue gas to be tested. N with gas pump 2 Back-purging cleaning pipeline and filter (the filter prevents solid particles in the flue gas from entering the detection system) turns on the heating and preheating sampling flue gas pipeline, and the temperature is set at 380°C.

[0061] Set the gas volume flow meters in the flue gas upstream pipeline 5 and the flue gas downstream pipeline 6 to 300ml / min, which can estimate the amount of SO in the flue gas x Less than 500mg / Nm 3 , add 50.0ml deoxygenated deionized water, 8.0mg hydrogen peroxide (analytical pure), 18.0mgN to the oxidation reactor 7 a OH (analytical pure). Add 50.0ml deoxygenated deionized wate...

Embodiment 2

[0069] Example 2 The flue gas temperature of an economizer is 300°C. Before sampling, it is necessary to select a suitable sampling point on the flue gas pipeline, and set a sampling port with a diameter of DN40 at the sampling point, insert the standard gas sampling probe into the flue, and connect it with a flange to collect the flue gas to be tested. N with gas pump 2 Back purge to clean the pipeline and filter, (the filter prevents solid particles in the flue gas from entering the detection system) Turn on the heating and preheating sampling flue gas pipeline, and set the temperature to 300°C.

[0070] Set the gas volume flowmeters in the flue gas upstream pipeline 5 and the flue gas downstream pipeline 6 to 200ml / min, which can estimate the amount of SO in the flue gas x At 500-1000mg / Nm 3 Range, add 100.0ml deoxygenated deionized water, 16.0mg hydrogen peroxide (analytical pure), 36.0mg NaOH (analytical pure) into the oxidation reactor. Add 100.0ml deoxygenated deioni...

Embodiment 3

[0077] Example 3 The flue gas temperature of a certain chimney is 50°C. Before sampling, it is necessary to select a suitable sampling point on the flue gas pipeline, and set a sampling port with a diameter of DN40 at the sampling point, insert the standard gas sampling probe into the flue, and seal the connection. N with gas pump 2 Back purge cleans the pipeline and filter (the filter prevents solid particles in the flue gas from entering the detection system).

[0078] Turn on the heating and preheating sampling flue gas pipeline, and set the temperature to 50°C. Set the gas volume flow meter in the flue gas upstream pipeline 5 and the flue gas downstream pipeline 6 to 500ml / min, adopt scheme 1, add 50.0ml deoxygenated deionized water, 8.0mg hydrogen peroxide (analytical pure), 18.0mgN a OH (analytical pure). Add 50.0ml deoxygenated deionized water, 10.0mg iodine (analytically pure), 36mgNaOH (analytical pure) and 1d starch solution into the discoloration reactor. Turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com