SOI structure and manufacturing method thereof, MEMS device and manufacturing method thereof

A manufacturing method and device technology, which is applied in the field of SOI structure and manufacturing, and MEMS devices, can solve the problems that the reliability of devices cannot be effectively improved, and the insulation of isolation grooves is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

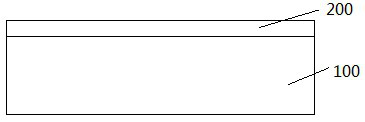

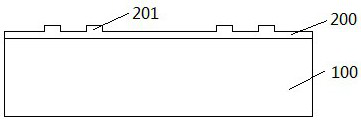

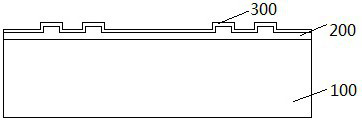

[0045] The following examples of this embodiment are all carried out by using the SOI structure as an example to realize isolation and insulation applications. First, an SOI structure and a method for manufacturing the SOI structure are disclosed, wherein the SOI structure is as follows Figure 6 As shown, it includes at least a first silicon layer 100 , an insulating layer and a second silicon layer 500 from bottom to top. The SOI structure (silicon on insulator) is often used in the manufacture of MEMS devices, and the buried oxide layer in the middle is mainly used to realize the insulation isolation between electrodes. Unlike the existing SOI structure that uses a silicon dioxide single-layer structure to form the buried oxide layer, the insulating layer in this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap