Titanium alloy hermetically sealed connector and production process thereof

A production process, titanium alloy technology, applied in the connection, parts of the connection device, dust-proof/splash-proof/leak-proof/waterproof/fireproof connection, etc., can solve the problem of inability to meet high-pressure airtightness requirements To reduce the impact of sealing, improve sealing reliability, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

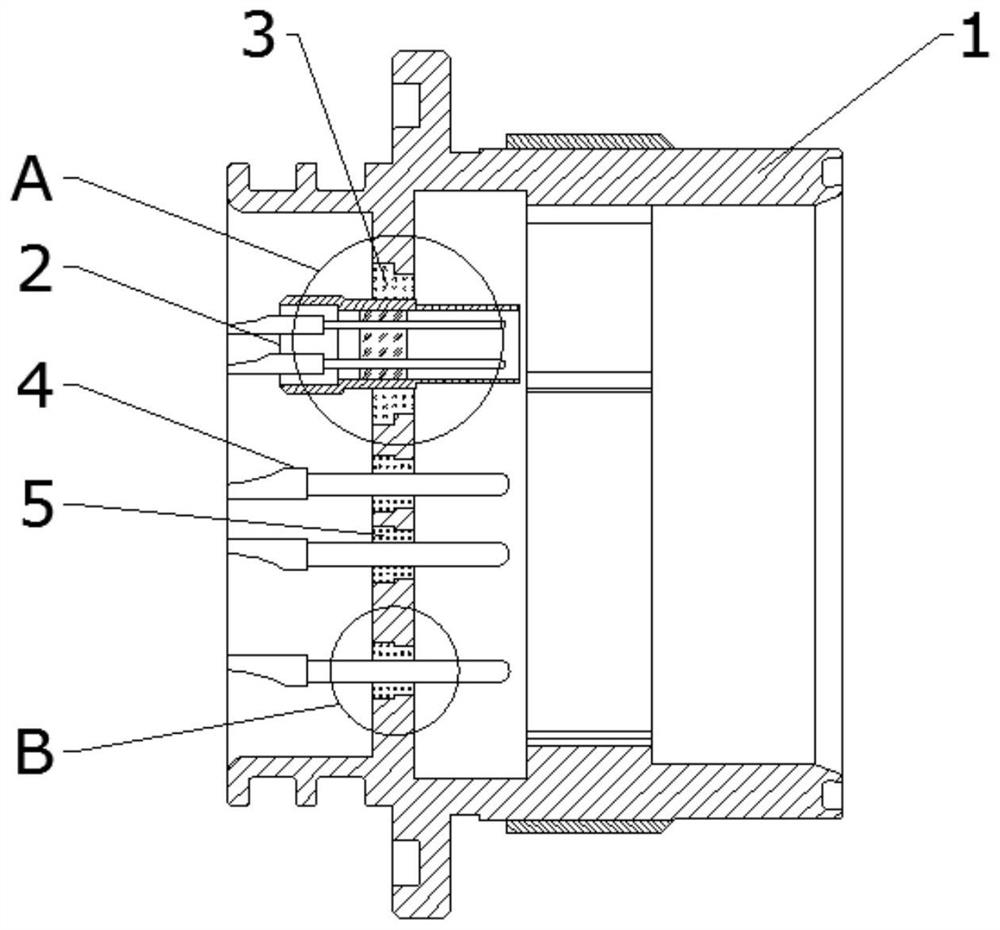

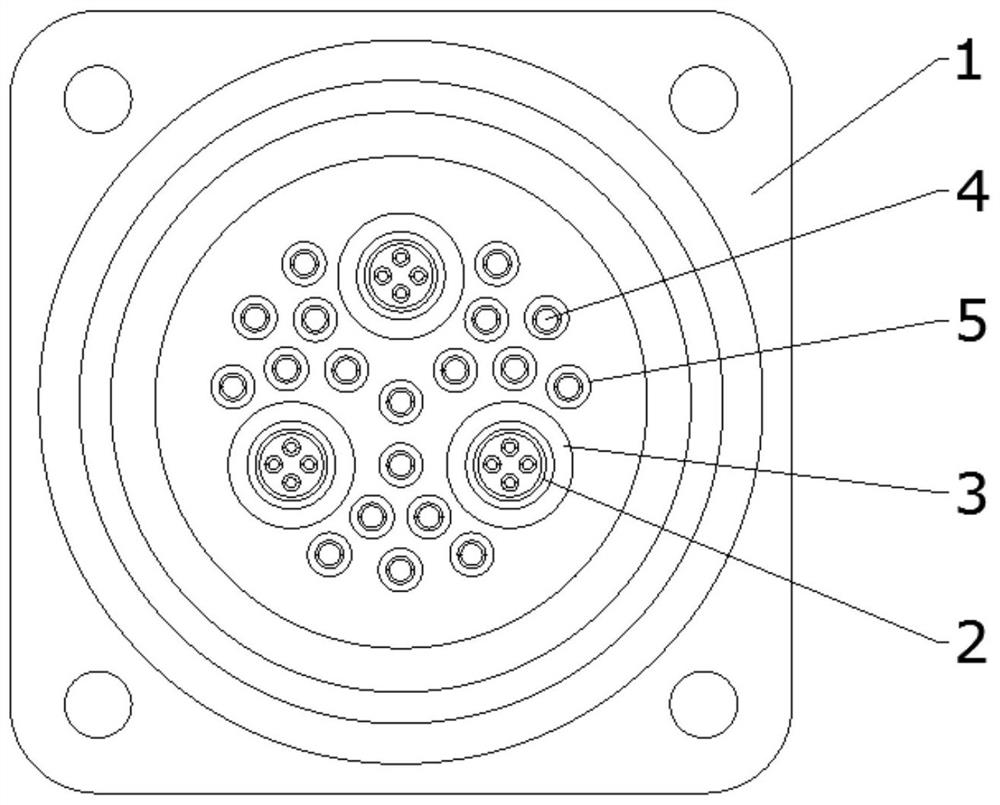

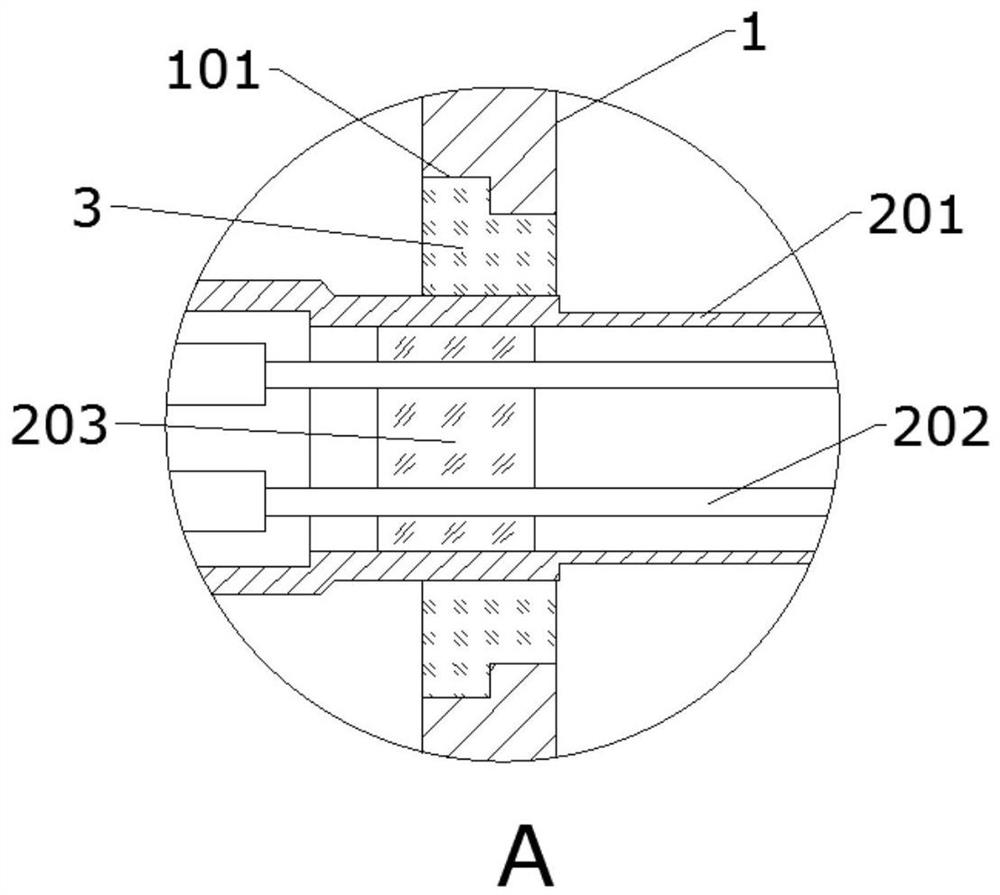

[0030] see Figure 1-4 As shown, a titanium alloy sealed connector includes a titanium alloy shell 1 made of TC4 titanium alloy, a first glass blank 3 made of BH-G / K glass, a second glass blank 5 and a third glass blank The blank 203 and the inner housing 201 made of Kovar alloy, the first contact pin 4 and the second contact pin 202, the inner housing 201, the second contact pin 202 and the third glass blank 203 are assembled into a joint assembly 2, the second The second pin 202 is installed inside the inner shell 201, the third glass blank 203 is installed between the second pin 202 and the inner shell 201, and the inner center of the titanium alloy shell 1 is provided with a number of uniformly distributed first sinks. hole 101 and the second counterbore 102, the joint assembly 2 is located inside the first counterbore 101, the first glass blank 3 is arranged between the joint assembly 2 and the first counterbore 101, and the first pin 4 is located in the second counterbor...

Embodiment 2

[0034] The titanium alloy sealed connector with the structure of Example 1 is manufactured according to the following steps:

[0035]Step S1, using clear water as the grinding liquid, and polishing the inner surfaces of the first counterbore 101 and the second counterbore 102 with aluminum oxide waterproof sandpaper, so that the inner surfaces of the first counterbore 101 and the second counterbore 102 are rough The thickness is 1.6 μm, and then electrochemically polish the titanium alloy shell 1 as a whole, and use nitrogen gas to dry it for later use; put the inner shell 201, the first pin 4 and the second pin 202 at 1000°C, hydrogen Purify in the atmosphere for 1h, then at 550℃, N 2 / 2%H 2 Oxidation treatment in O binary atmosphere for 5 minutes, cooled for later use;

[0036] Step S2: All the titanium alloy casing 1, the inner casing 201, the first pin 4, the second pin 202, the first glass blank 3, the second glass blank 5, and the third glass blank 203 processed in ste...

Embodiment 3

[0041] The titanium alloy sealed connector with the structure of Example 1 is manufactured according to the following steps:

[0042] Step S1, using clear water as the grinding liquid, and polishing the inner surfaces of the first counterbore 101 and the second counterbore 102 with aluminum oxide waterproof sandpaper, so that the inner surfaces of the first counterbore 101 and the second counterbore 102 are rough The thickness is 0.8 μm, and then electrochemically polish the titanium alloy shell 1 as a whole, and use nitrogen gas to dry it for later use; put the inner shell 201, the first pin 4 and the second pin 202 at 1000°C, hydrogen Purify in the atmosphere for 1h, then at 550℃, N 2 / 2%H 2 Oxidation treatment in a binary atmosphere for 8 minutes, cooled for later use;

[0043] Step S2: All the titanium alloy casing 1, the inner casing 201, the first pin 4, the second pin 202, the first glass blank 3, the second glass blank 5, and the third glass blank 203 processed in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com