Rubber latex and water-based adhesive composition

A rubber latex, polymer chain technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve problems such as environmental pollution, and achieve the effect of excellent initial bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

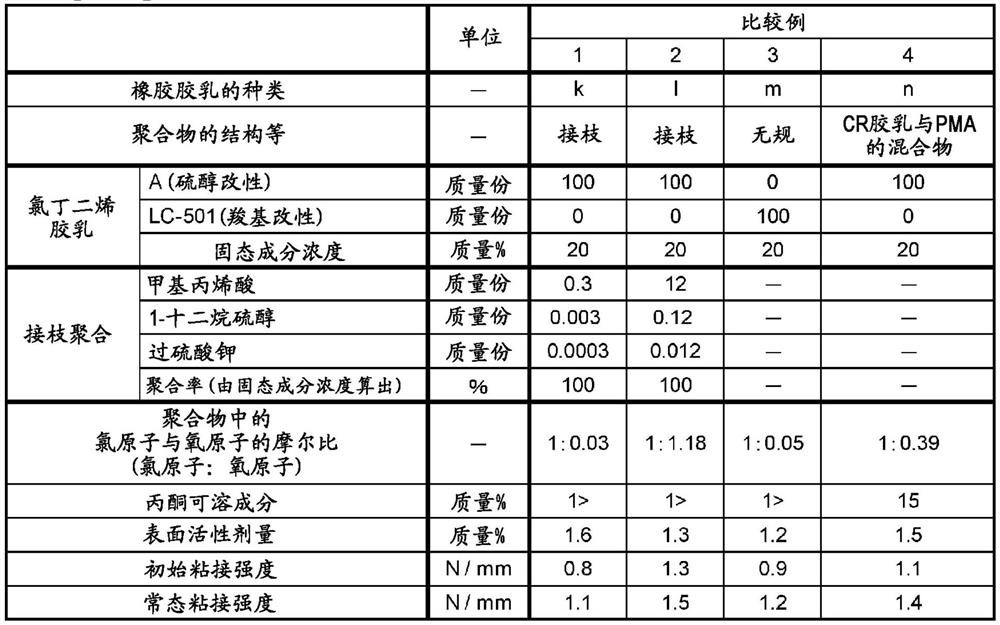

[0079] Hereinafter, although an Example demonstrates this invention, these Examples do not limit this invention.

[0080]

[0081] (production of chloroprene latex A)

[0082] Under a nitrogen stream, 150 parts by mass of water, 4.0 parts by mass of sodium dodecylbenzenesulfonate (manufactured by Kao Corporation: NEOPELEX G-65 (purity: 65% by mass)), 4.0 parts by mass of naphthalenesulfonate, were charged into a reactor with an inner capacity of 10 L. After 0.7 parts by mass of acid formaldehyde condensate sodium salt (manufactured by Kao Corporation: DEMOL N) and 0.5 parts by mass of sodium bisulfite, the solid content was dissolved to obtain a solution. Then, stirring the solution, 100 parts by mass of chloroprene and 0.55 parts by mass of 1-dodecanethiol were added to the solution. Using potassium persulfate as a polymerization initiator, polymerization was started at 10° C. under a nitrogen atmosphere. When the polymerization rate reached 75%, an emulsion containing 0....

Embodiment 1

[0086] In Example 1, the usage-amount of methacrylic acid was changed to 4 parts by mass, and the usage-amount of 1-dodecanethiol was changed to 0.04 parts by mass, and a graft copolymer rubber was obtained in the same manner as in Example 1. Latex b.

Embodiment 3

[0088] In Example 1, the usage-amount of methacrylic acid was changed to 8 parts by mass, and the usage-amount of 1-dodecanethiol was changed to 0.08 parts by mass, except that, a graft copolymer was obtained in the same manner as in Example 1 rubber latex c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com