Centralized fly ash high-temperature melting vitrification utilization system and method

A high-temperature melting and vitrification technology, which is applied in the removal of solid waste and waste treatment, can solve the problems of incomplete vitrification, large fuel consumption, and complicated treatment process, and achieve good removal effect, high degree of automation, The effect of a compact system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make those skilled in the art better understand the technical scheme of the present invention, preferred embodiments of the present invention are described below in conjunction with specific examples, but can not be interpreted as the limitation of this patent.

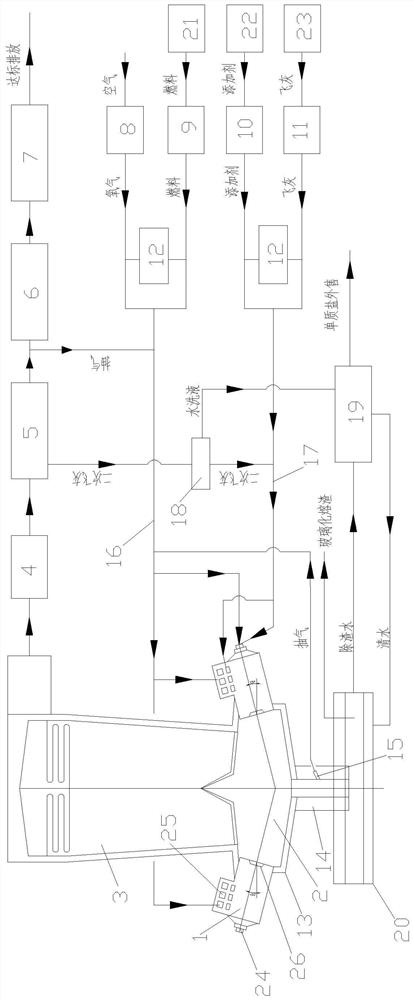

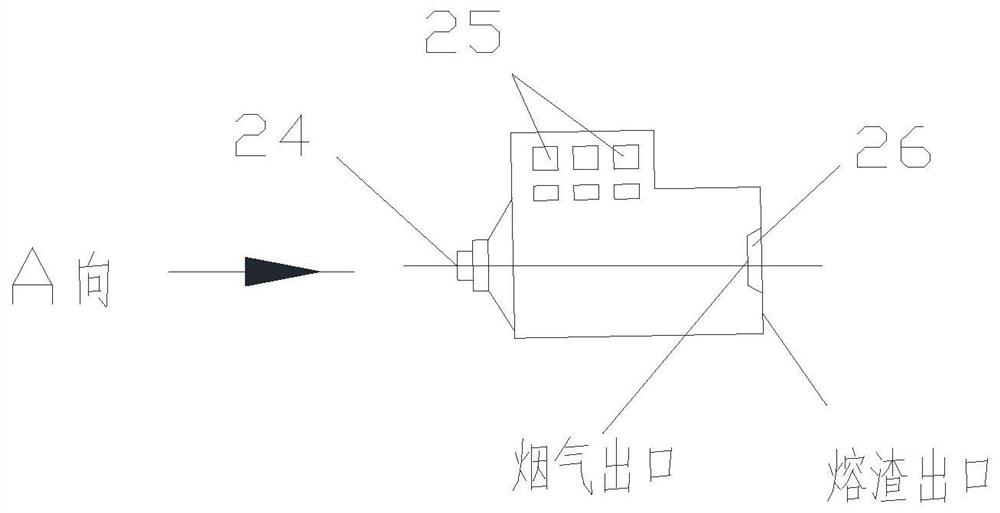

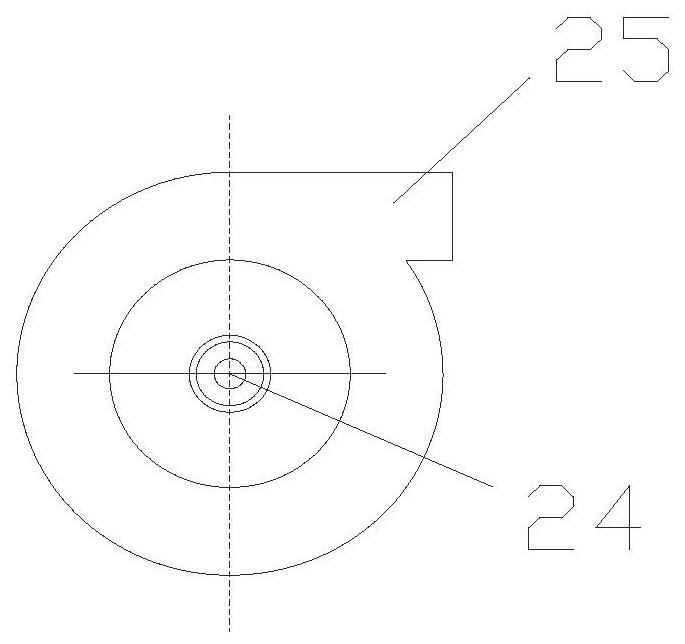

[0037] Such as Figure 1-3 As shown, the fly ash burned by all incinerators in the administrative area of a certain province will be sent to the fly ash centralized treatment station of the present invention, in the fly ash centralized treatment station, pure oxygen is made by oxygen generator 8, and fly ash is produced by The sealed storage tank 23 is stored, the additive is stored by the additive storage tank 22, and the fuel is stored by the fuel storage tank 21. The additive, fuel, stored fly ash and the produced pure oxygen are sent to the fly ash high temperature molten glass of the present invention through pneumatic conveying The system adopts the principle of high-temperature vortex combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com