A kind of preparation method and application of calcium cuprate nanosheet

A nanosheet and aspect technology, which is applied in the field of nonlinear optical material preparation, can solve the problem of reducing the size to nanometer scale, and achieve the effect of large third-order nonlinear coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

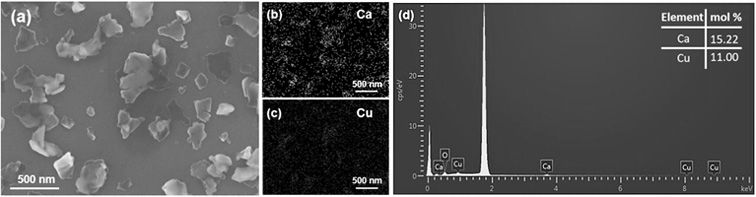

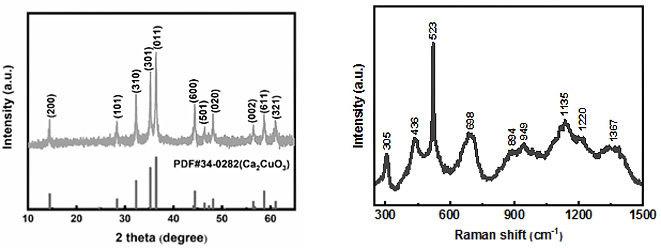

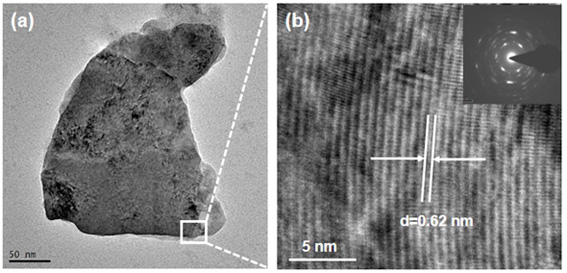

[0025] a Ca 2 CuO 3 The preparation steps of nanosheets are:

[0026] (1) Weigh 6.28 mmol Ca(NO 3 ) 2 ·4H 2 O, 3.14 mmol Cu(NO 3 ) 2 ·3H 2 O and 12.56 mmol C 6 H 8 O 7 ·H 2 O in a beaker, add 16 mL of diethylene glycol monobutyl ether to dissolve by ultrasonic stirring to obtain a stable blue solution;

[0027] (2) The obtained blue solution was placed in a water bath at 80 °C and stirred at constant temperature for 2 h, and then transferred to an oil bath at 130 °C and stirred at constant temperature for 2 h to obtain a blue-white sticky substance;

[0028](3) The obtained material was transferred to an evaporating dish, placed on a universal electric furnace for evaporation to dryness, and a brown powder was obtained. The obtained brown powder was ground into fine powder, placed in a crucible, sintered at 900 °C for 1 h, cooled naturally and ground again to obtain a bulk powder Ca. 2 CuO 3 ;

[0029] (4) Take 0.75 g bulk powder Ca 2 CuO 3 Put it into a ball ...

Embodiment 2

[0032] a Ca 2 CuO 3 The preparation steps of nanosheets are:

[0033] (1) Weigh 6.28 mmol Ca(NO 3 ) 2 ·4H 2 O, 3.14 mmol Cu(NO 3 ) 2 ·3H 2 O and 18.84 mmol C 6 H 8 O 7 ·H 2 O in a beaker, add 10 mL of diethylene glycol monobutyl ether to dissolve by ultrasonic stirring to obtain a stable blue solution;

[0034] (2) The obtained blue solution was placed in a water bath at 60 °C and stirred at constant temperature for 1 h, and then transferred to an oil bath at 100 °C and stirred at constant temperature for 1 h to obtain a blue-white sticky substance;

[0035] (3) The obtained material was transferred to an evaporating dish, placed on a universal electric furnace for evaporation to dryness, and a brown powder was obtained. The obtained brown powder was ground into fine powder, placed in a crucible, sintered at 600 °C for 1 h, cooled naturally and ground again to obtain a bulk powder Ca. 2 CuO 3 ;

[0036] (4) Take 0.5 g of bulk powder Ca 2 CuO 3 Put it into a ba...

Embodiment 3

[0039] a Ca 2 CuO 3 The preparation steps of nanosheets are:

[0040] (1) Weigh 6.28 mmol Ca(NO 3 ) 2 ·4H 2 O, 3.14 mmol Cu(NO 3 ) 2 ·3H 2 O and 25.12 mmol C 6 H 8 O 7 ·H 2 O in a beaker, add 20 mL of diethylene glycol monobutyl ether to dissolve by ultrasonic stirring to obtain a stable blue solution;

[0041] (2) The obtained blue solution was placed in a water bath at 100 °C and stirred at constant temperature for 3 h, and then transferred to an oil bath at 150 °C and stirred at constant temperature for 3 h to obtain a blue-white sticky mass;

[0042] (3) The obtained material was transferred to an evaporating dish, placed on a universal electric furnace for evaporation to dryness, and a brown powder was obtained. The obtained brown powder was ground into fine powder, placed in a crucible, sintered at 1200 °C for 3 h, cooled naturally and ground again to obtain a bulk powder Ca. 2 CuO 3 ;

[0043] (4) Take 1 g of bulk powder Ca 2 CuO 3 Put it into a ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com