A resource-saving lightweight environmental protection tundish working lining and preparation method thereof

A resource-saving and tundish technology, applied in the field of refractory materials, can solve the problems that refractory materials cannot meet the requirements of cleanliness and thermal insulation effect, the consumption of refractory materials remains high, and the heat dissipation speed of the tundish lining is fast, etc. Anti-slag penetration performance, achieve the effect of light weight and cost saving of refractory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

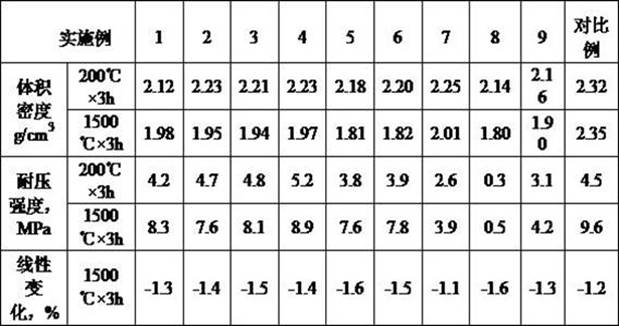

Examples

Embodiment 1

[0047] The resource-saving lightweight environment-friendly tundish working lining described in this embodiment is calculated according to the parts by mass, and its preparation raw materials include the following components:

[0048] 5 parts of magnesite with a particle size of 1-3mm; 10 parts of magnesite with a particle size of 0.25-1mm; 15 parts of forsterite with a particle size of 1-3mm; 45 parts of forsterite with a particle size of 0.25-1mm; 10 parts of dead-burned magnesia fine powder no larger than 0.075mm; binder: 4 parts of magnesium sulfate, 4 parts of sulfamic acid, 2 parts of magnesium chloride; 1 part of paper fiber; modifier: 2 parts of graphite, 2 parts of SiC; Agent: 0.2 parts of silica powder with a purity of 95%.

[0049] The preparation method of the resource-saving lightweight environment-friendly tundish working lining of this embodiment includes the following steps:

[0050] S1. According to the selected mass ratio, pre-mix the binder and the preserva...

Embodiment 2

[0053] The resource-saving lightweight environment-friendly tundish working lining described in this embodiment is calculated according to the parts by mass, and its preparation raw materials include the following components:

[0054] 10 parts of magnesite with a particle size of 1-3mm; 20 parts of magnesite with a particle size of 0.25-1mm; 10 parts of forsterite with a particle size of 1-3mm; 28.5 parts of forsterite with a particle size of 0.25-1mm; 15 parts of dead-burned magnesia fine powder not larger than 0.075mm; binder: 4 parts of magnesium sulfate, 2 parts of sulfamic acid, 2 parts of sodium metasilicate; 0.5 part of paper fiber; modifier: 4 parts of graphite, SiC 4 parts; preservative: 0.2 parts of silicon micropowder with a purity of 92%.

[0055] The preparation method of the resource-saving lightweight environment-friendly tundish working lining of this embodiment includes the following steps:

[0056] S1. According to the selected mass ratio, pre-mix the binder...

Embodiment 3

[0059] The resource-saving lightweight environment-friendly tundish working lining described in this embodiment is calculated according to the parts by mass, and its preparation raw materials include the following components:

[0060] 15 parts of magnesite with a particle size of 1-3mm; 25 parts of magnesite with a particle size of 0.25-1mm; 5 parts of forsterite with a particle size of 1-3mm; 29.4 parts of forsterite with a particle size of 0.25-1mm; 15 parts of dead burnt magnesia fine powder not larger than 0.075mm; binder: 2 parts of magnesium sulfate, 4 parts of sulfamic acid, 3 parts of sodium metasilicate; 0.6 part of paper fiber; modifier: 2 parts of graphite, SiC 2 parts; preservative: 0.2 parts of silicon micropowder with a purity of 95%.

[0061] The preparation method of the resource-saving lightweight environment-friendly tundish working lining of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com