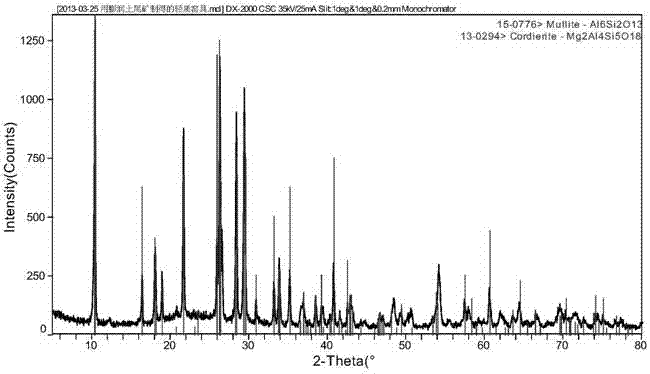

Light cordierite-mullite kiln furniture materials prepared through bentonite tailings

A technology of bentonite tailings and mullite kiln, which is applied in the field of kiln furniture with light cordierite-mullite performance, light cordierite-mullite kiln furniture materials, and can solve thermal shock stability Not good enough, high consumption of raw materials and fuel, poor high temperature resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

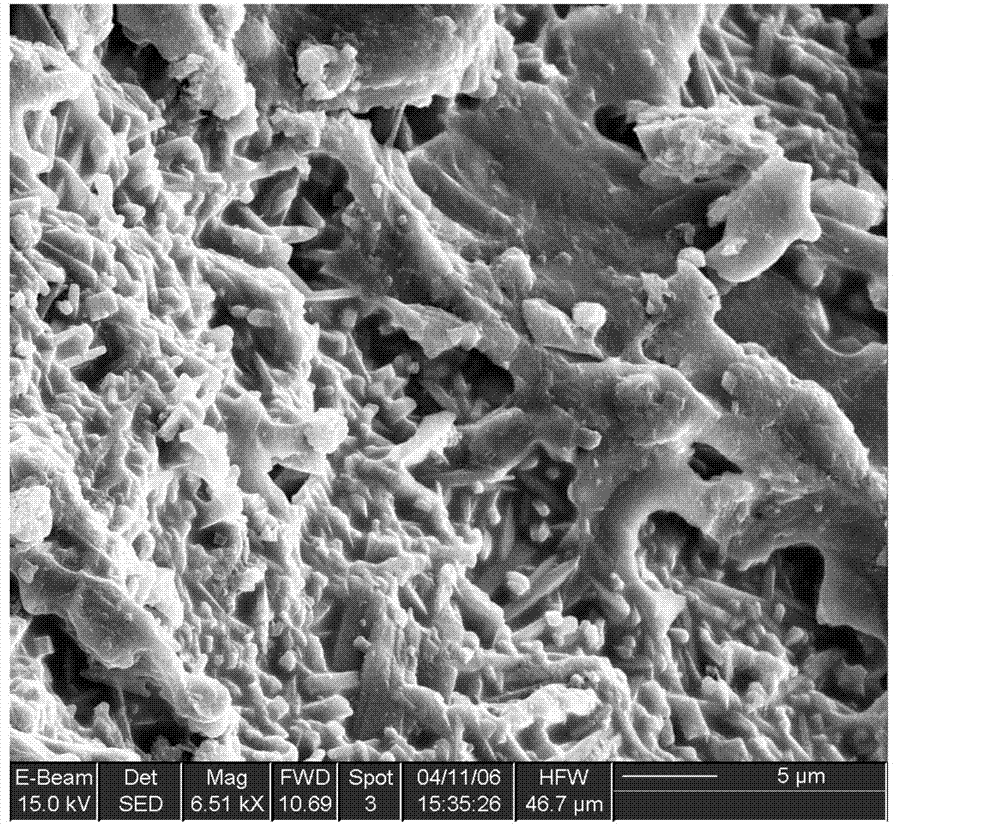

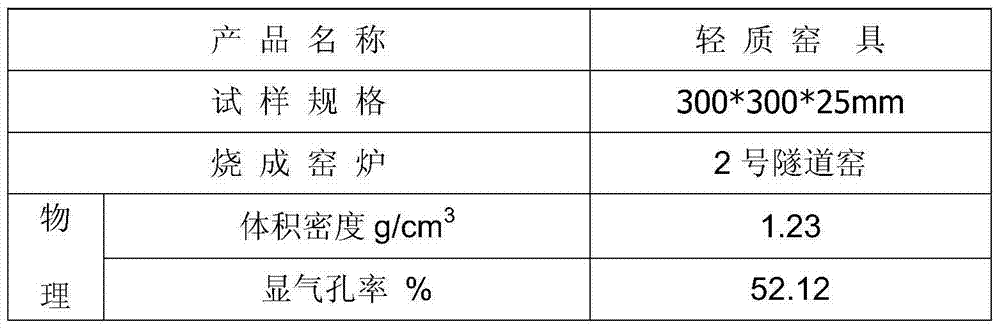

[0038] Formula: bentonite tailings 25%, light mullite 21%, sillimanite 10%, chlorite 14%, low-sodium alumina 8%, cordierite-mullite kiln furniture waste 18%, wood flour 4 %, plus 0.4% cellulose.

[0039] Bentonite tailings: the natural bentonite ore is washed with water, centrifugal mud dumping and other methods to extract the high-purity bentonite components with high montmorillonite content in the bentonite ore, and the remaining waste, the Al of the bentonite tailings 2 o 3 The content is 10-14%, and the MgO content is 2-6%. It has plasticity and cohesiveness after being exposed to water.

[0040] Mixing: According to the process mentioned above, add water at a ratio of 7% (solid content as the basis) to prepare a mixture, and seal and trap the material for 24 hours.

[0041] Forming: single-sided hydraulic forming, with 140KGF / CM 2 The pressure is used to form it, and the solid shed board green body of 304*304*25.2mm is obtained. The green body can be moved by hand and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com