Environment-friendly water-resistant zein adhesive and preparation method thereof

A technology of zein and adhesives, which is applied in the field of chemical adhesives, can solve the problems of insufficient water resistance and complicated preparation process of adhesives, and achieve the effect of improving poor water resistance, good stickiness, and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

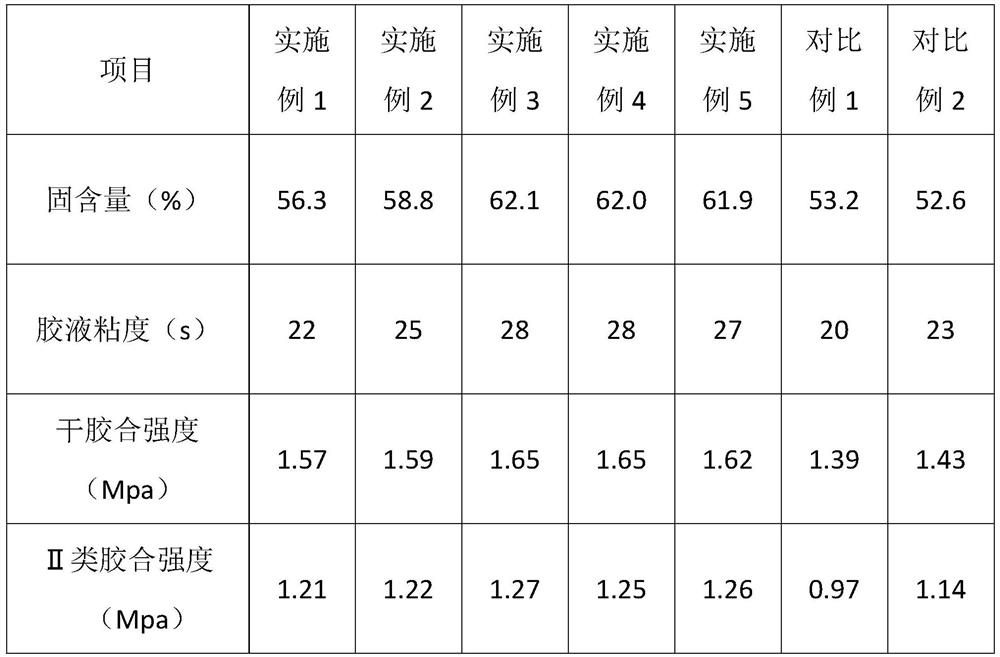

Examples

Embodiment 1

[0025] A preparation method of an environmental-friendly water-resistant zein adhesive, comprising the steps of:

[0026] Step S1: Mix 5 g of zein with 95 g of an alcohol solution of dodecylamine with a molar concentration of 200 mmol / L, stir at room temperature for 40 min to obtain a mixed solution, and then pour 10 g of the mixed solution into a mold (5.5 cm×5.5 cm×3.0cm), placed in an oven at 70°C for 4 hours to obtain an amino-modified zein complex film;

[0027] Step S2: Immerse 10 g of the amino-modified zein complex film prepared in step S1 into 1 wt % AgNO with a volume of 100 ml 3 in the solution, stirring at 40°C for 30 minutes to completely dissolve the amino-modified zein complex film to obtain the chelate;

[0028] Step S3: 0.6g graphene oxide was added to 150ml chloroform, ultrasonically dispersed, then 5mmol pentaerythritol tetraester and 5mmol azobisisobutyronitrile were added thereto, and 2 Atmosphere, under the condition that the reaction temperature is 70°...

Embodiment 2

[0031] A preparation method of an environmental-friendly water-resistant zein adhesive, comprising the steps of:

[0032] Step S1: Mix 5 g of zein with 95 g of an alcohol solution of dodecylamine with a molar concentration of 200 mmol / L, stir at room temperature for 40 min to obtain a mixed solution, and then pour 10 g of the mixed solution into a mold (5.5 cm×5.5 cm×3.0cm), placed in an oven at 70°C for 4 hours to obtain an amino-modified zein complex film;

[0033] Step S2: Immerse 10 g of the amino-modified zein complex film prepared in step S1 into 2.5 wt % AgNO with a volume of 100 ml 3 in the solution, stirring at 40°C for 30 minutes to completely dissolve the amino-modified zein complex film to obtain the chelate;

[0034] Step S3: 0.6g graphene oxide was added to 150ml chloroform, ultrasonically dispersed, then 5mmol pentaerythritol tetraester and 5mmol azobisisobutyronitrile were added thereto, and 2 Atmosphere, under the condition that the reaction temperature is 7...

Embodiment 3

[0037] A preparation method of an environmental-friendly water-resistant zein adhesive, comprising the steps of:

[0038] Step S1: Mix 5 g of zein with 95 g of an alcohol solution of dodecylamine with a molar concentration of 200 mmol / L, stir at room temperature for 40 min to obtain a mixed solution, and then pour 10 g of the mixed solution into a mold (5.5 cm×5.5 cm×3.0cm), placed in an oven at 70°C for 4 hours to obtain an amino-modified zein complex film;

[0039] Step S2: Immerse 10 g of the amino-modified zein complex film prepared in step S1 into 5 wt % AgNO with a volume of 100 ml 3 in the solution, stirring at 40°C for 30 minutes to completely dissolve the amino-modified zein complex film to obtain the chelate;

[0040] Step S3: 0.6g graphene oxide was added to 150ml chloroform, ultrasonically dispersed, then 5mmol pentaerythritol tetraester and 5mmol azobisisobutyronitrile were added thereto, and 2 Atmosphere, under the condition that the reaction temperature is 70°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com