Steel structure building based on steel structure building and having collapse protection function

A protection function and steel structure technology, which is applied in the direction of building components, building structure, infrastructure engineering, etc., can solve the problems of overall collapse of the building, collapse of the collapsed protective structure, etc., so as to alleviate the bearing capacity, improve the stability, and strengthen the firmness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

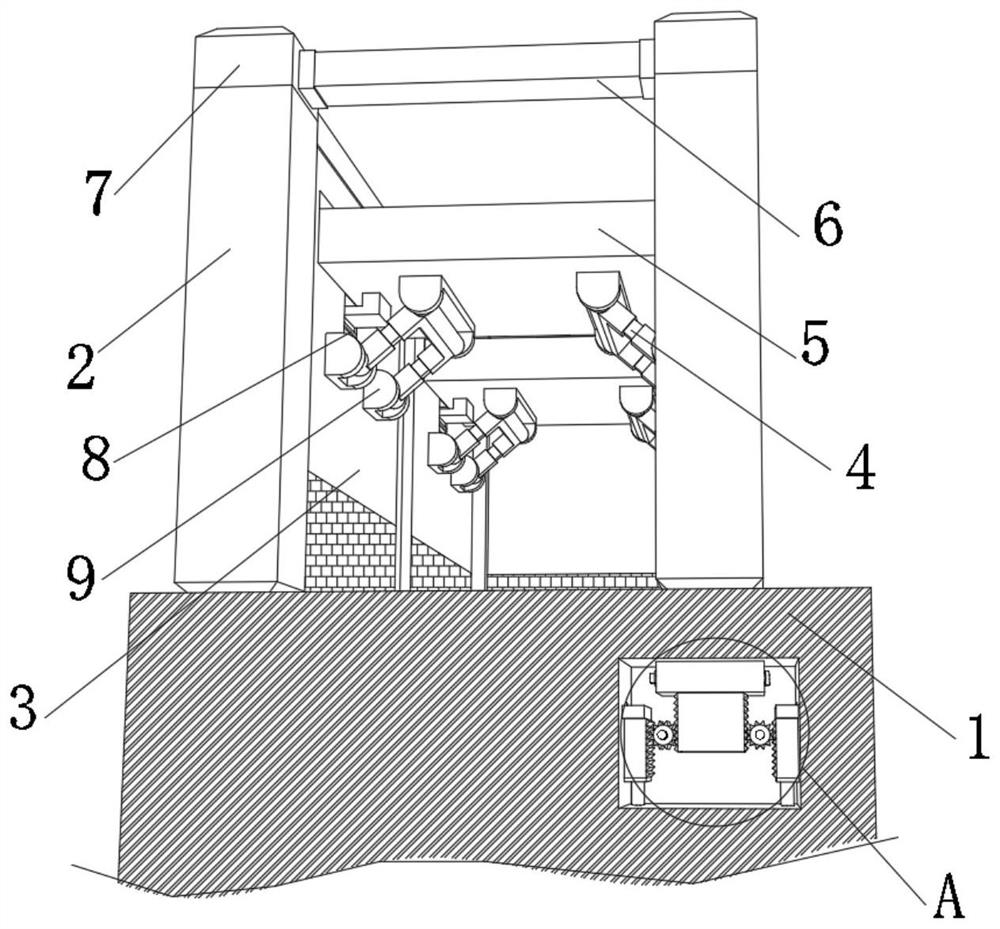

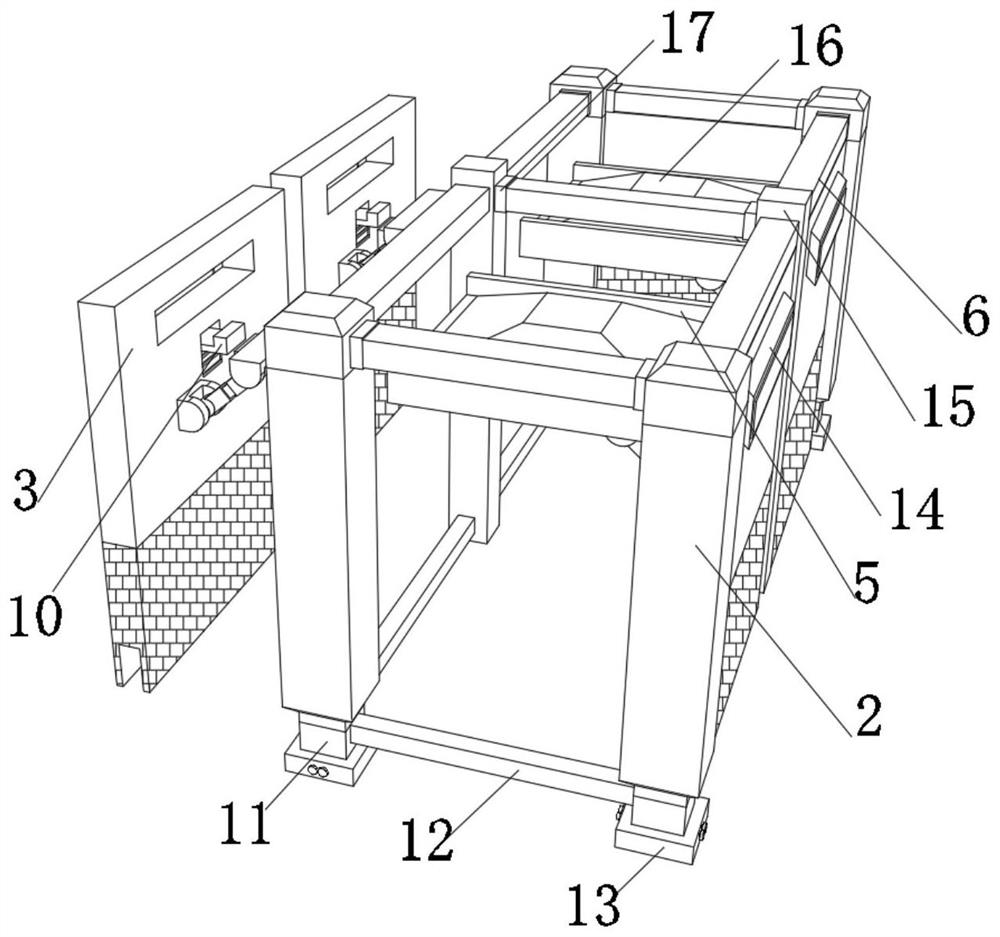

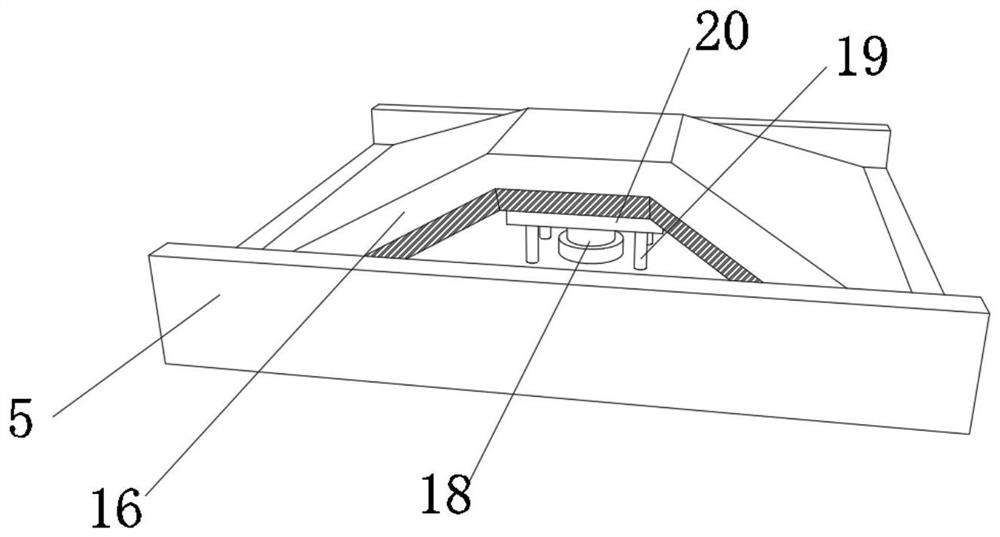

[0038] A steel structure building with collapse protection function based on the steel structure building, such as figure 1 , figure 2 and Figure 7 As shown, it includes a support part laid in the ground layer 1 through a plurality of base support structures, and the support part includes a plurality of support assemblies 2, a plurality of trusses 6, a plurality of connecting steel columns 12 and at least two connecting columns 15; The outer walls of a plurality of connecting steel columns 12 are stacked with mixed wallboards 3, and one side of the mixed wallboards 3 is respectively matched with one side of the supporting assembly 2 or one side of the connecting column 15, forming two opposing positions. The outer wall of one side of the hybrid wallboard 3 is provided with a lifting groove, and the bottom inner walls of the two lifting grooves are respectively fixed with buffer columns by bolts, and the inner walls of the two lifting grooves are slidably connected to the sa...

Embodiment 2

[0045] A steel structure building with collapse protection function based on the steel structure building, such as figure 1 and Figure 10 As shown, in order to improve the stability of the steel building; this embodiment makes the following improvements on the basis of embodiment 1: the inner wall of the stratum 1 is provided with concrete foundation pits, and the number of concrete foundation pits is the same as the number of support assemblies 2 , the opposite side inner walls of the concrete foundation pit are provided with slide rails 39, and the inner walls of the two slide rails 39 are slidably connected with a movable seat 42, and the top outer walls of the movable seat 42 are fixed with protective plates by bolts, and the movable seat The outer wall of one side of 42 is meshed with gear 41 through teeth; When an earthquake occurs or the material above the building collapses, the supporting part will shake up and down due to the weight, and the supporting assembly 2 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com