Material hardness detection device based on multi-sensor fusion

A multi-sensor fusion and detection device technology, which is applied in the direction of measuring devices, test material hardness, instruments, etc., can solve the problems affecting the accuracy of measurement, low efficiency, and limited working space, so as to improve timeliness and accuracy, reduce The effect of occupying space and increasing the conveying density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

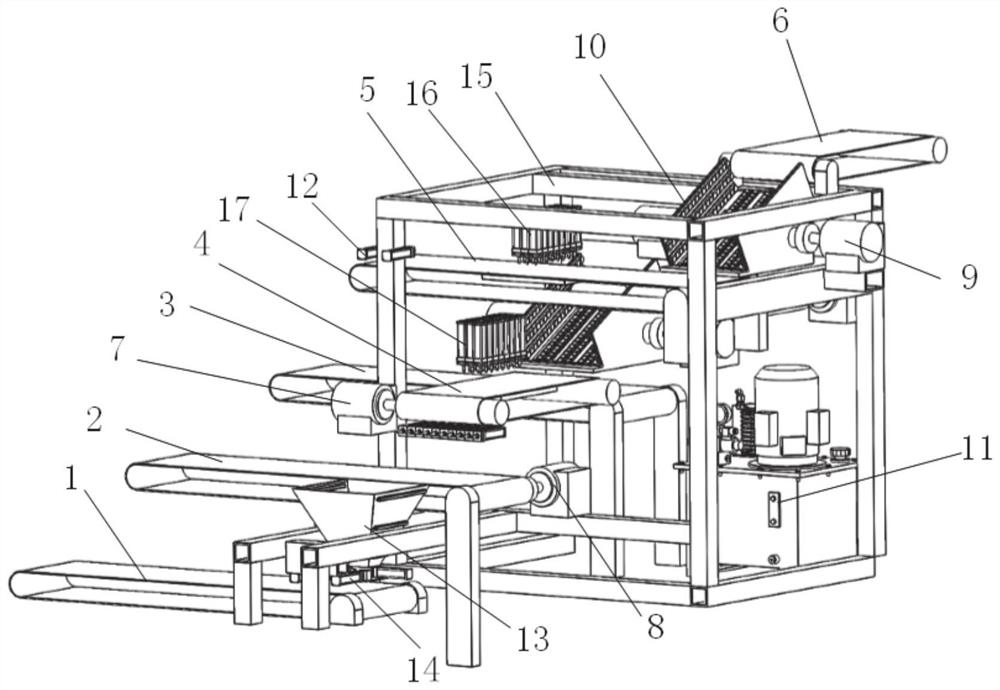

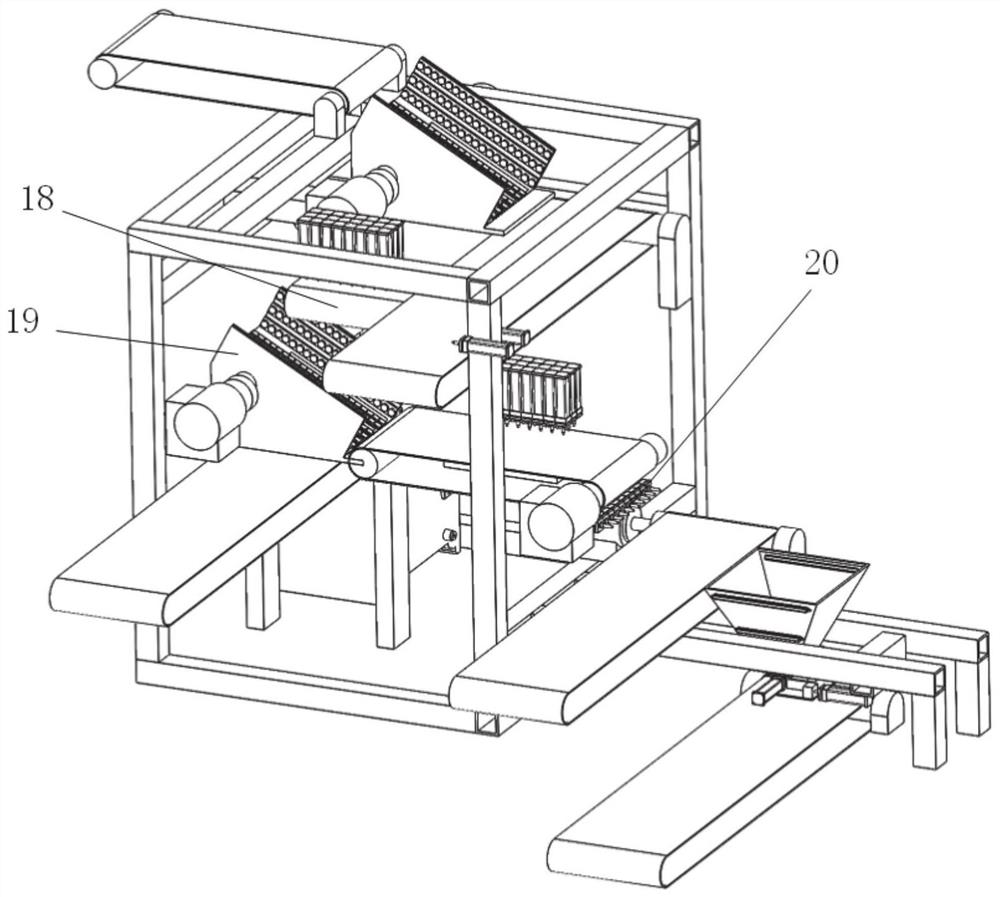

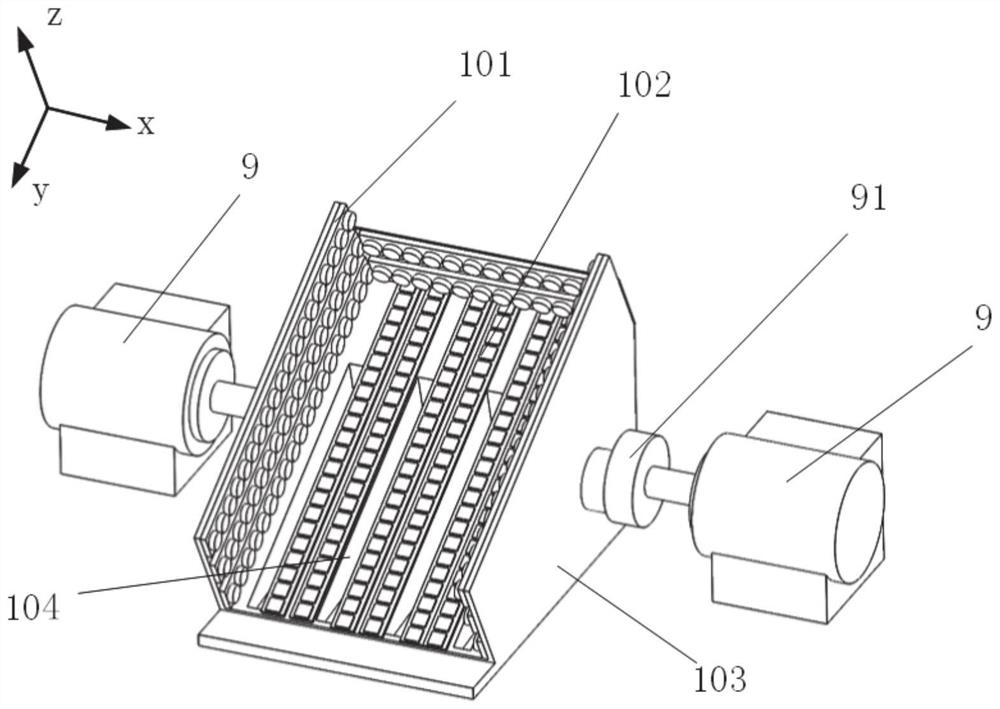

[0034] In a typical embodiment of the present disclosure, such as Figure 1-Figure 8 As shown, a material hardness detection device based on multi-sensor fusion is given.

[0035] It mainly includes a conveyor belt, a driving mechanism, a sieve bucket, a material pushing mechanism 20, a beating mechanism, and a detection mechanism, all of which are installed through the frame 15 structure to stabilize its working position. Among them, along the moving path of the material, the conveyor belt sequentially connects the sieve bucket, the beating mechanism, the pushing mechanism 20, and the detection mechanism in series, so that the material can be screened, detected, corrected or measured through the above-mentioned mechanisms in sequence, and the screening initially meets the demand. After the material is finished, the shape of the material is inspected and corrected, and the material that meets the demand is delivered to the testing mechanism to measure the hardness of the mater...

Embodiment 2

[0073] In another embodiment of the present disclosure, as Figure 1-Figure 8 As shown, a working method of a material hardness detection device based on multi-sensor fusion as described in Embodiment 1 is given.

[0074] Include the following steps:

[0075] (1) Multiple materials fall into the sixth conveyor belt 6 position;

[0076] (2) The sixth conveyor belt 6 sends a plurality of materials into the first sieve bucket 10;

[0077] (3) The first screening bucket 10 screens the falling materials for the first time

[0078] (4) After the first screening, qualified materials enter the seventh conveyor belt 18, and unqualified materials fall into the fifth conveyor belt 5;

[0079] (5) The material falling into the fifth conveyor belt 5 is conveyed to the waste place;

[0080] (6) The material on the seventh conveyor belt 18 passes through the first striking mechanism 16, and the shape of the target material is changed for the first time; if the material on the seventh con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com