Subsurface crack size measurement method based on surface wave and BP neural network

A BP neural network, crack size technology, applied in measuring devices, material analysis by optical means, instruments, etc., to achieve the effect of high precision and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

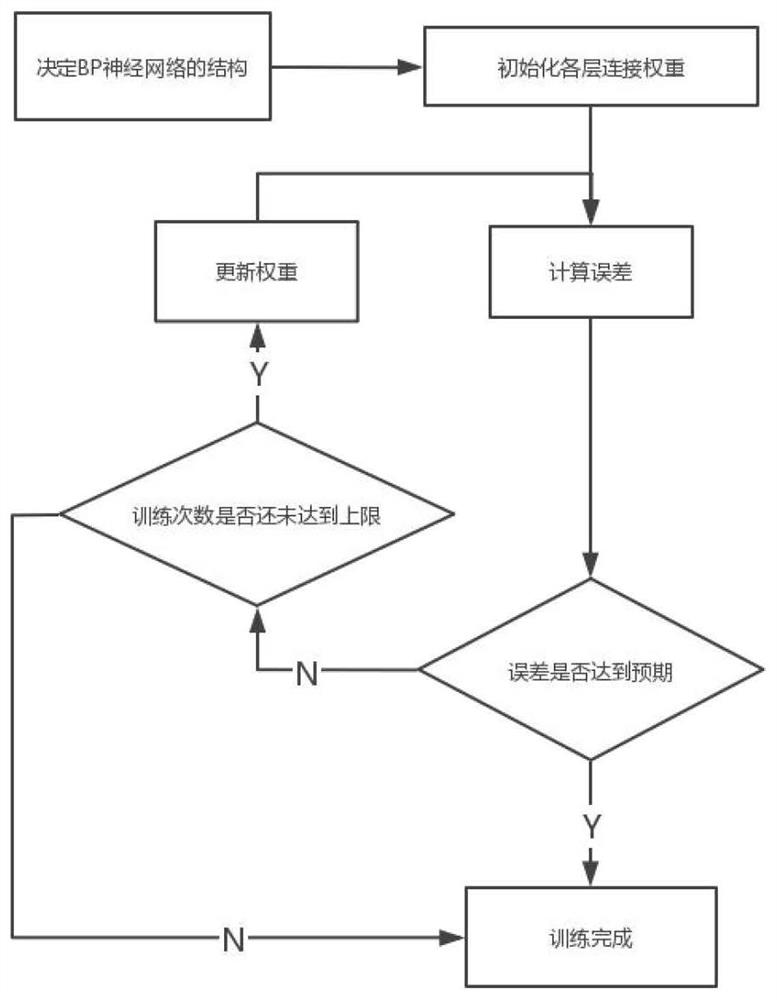

[0041] The present invention is to detect the depth and height of the subsurface cracks produced in the processing of precision machining materials, so as to facilitate subsequent processing to remove the defect layer, and proposes a quantitative measurement method for subsurface cracks based on ultrasonic surface wave frequency domain parameters. The specific plan is as follows:

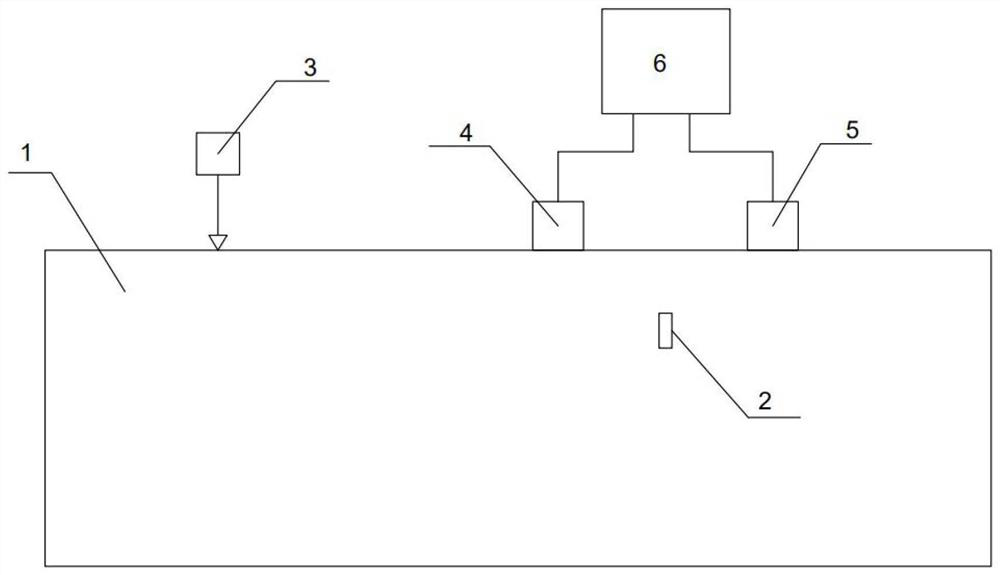

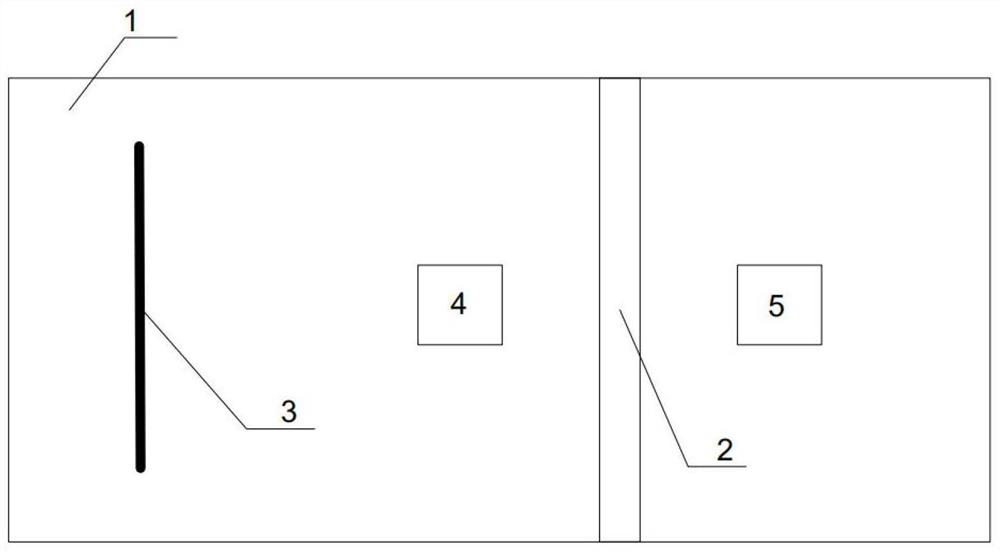

[0042] The quantitative measurement method adopts a subsurface crack quantitative measurement device based on ultrasonic surface wave frequency domain parameters, including a pulsed laser probe 3 , a first ultrasonic probe 4 and a second ultrasonic probe 5 . Both the first ultrasonic probe 4 and the second ultrasonic probe 5 are attached to the workpiece 1 and are respectively located on both sides of the subsurface crack 2 . The pulsed laser probe 3 is arranged on the side of the first ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com