Preparation method for improving luminous efficiency of LED packaging device by using amorphous photonic structure

A technology of LED encapsulation and photonic structure, which is applied in the direction of photomechanical equipment, semiconductor devices, and photoplate-making process of pattern surface, etc. It can solve the problems that it is difficult to increase the light extraction efficiency, and achieve significant light extraction efficiency, high improvement, and improved The effect of light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

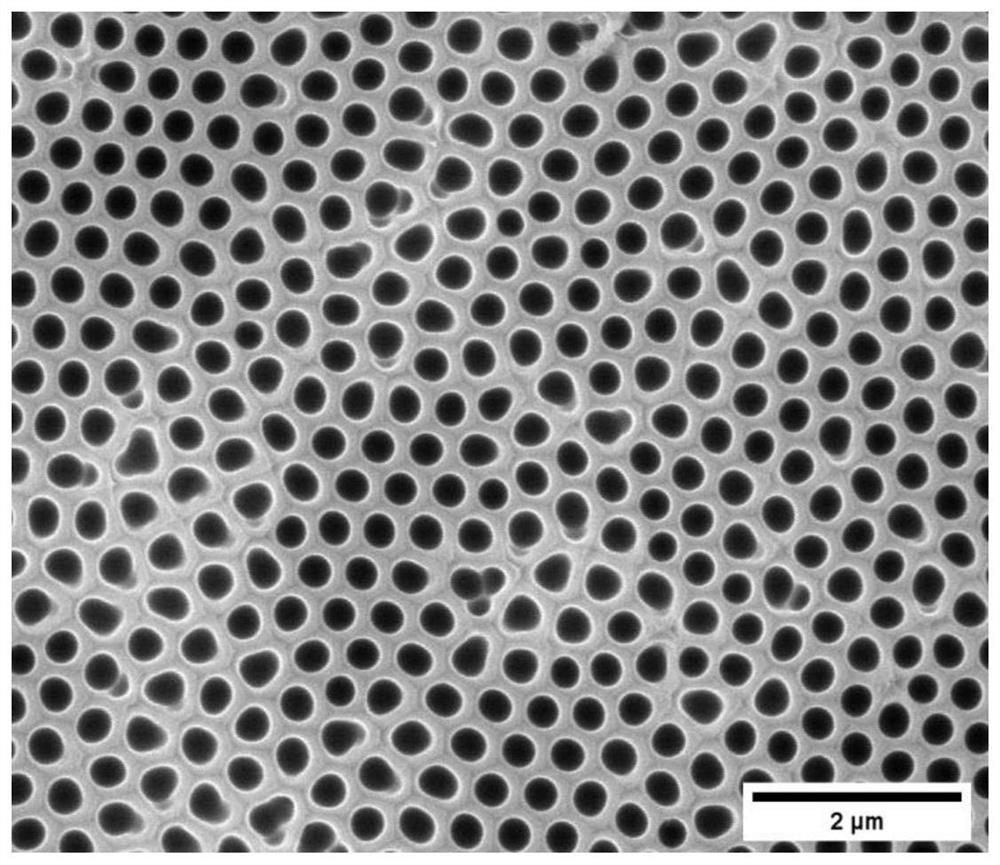

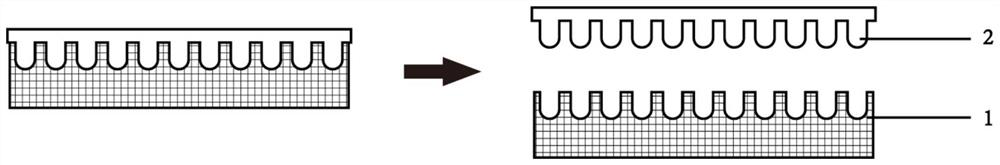

[0103] In this embodiment, a GaN-based blue LED packaging device with a small curvature surface of an AAO pattern is prepared, and the pattern on the hard template is an array of holes.

[0104] The preparation method for improving the light extraction efficiency of LED packaging devices by using an amorphous photonic structure in this embodiment includes the following steps:

[0105] 1) Preparation of AAO template with amorphous photonic structure with AAO pattern by secondary anodic oxidation method:

[0106] a) After the high-purity aluminum sheet is electrochemically polished, the aluminum sheet is used as an anode and immersed in a constant temperature 0.005-0.5mol / L phosphoric acid electrolyte for an anodic oxidation reaction. Self-assembled nanopore arrays;

[0107] b) immersing the aluminum sheet after an anodic oxidation reaction in a constant temperature deoxidation layer solution to remove the oxide layer on the surface of the aluminum sheet, leaving an array of na...

Embodiment 2

[0124] In this embodiment, a GaN-based blue LED packaging device with a large curvature surface of an AAO pattern is prepared, and the pattern on the hard template is an array of holes.

[0125] The preparation method for improving the light extraction efficiency of LED packaging devices by using an amorphous photonic structure in this embodiment includes the following steps:

[0126] 1) Preparation of AAO template with amorphous photonic structure with AAO pattern by secondary anodic oxidation method:

[0127] a) After the high-purity aluminum sheet is electrochemically polished, the aluminum sheet is used as an anode and immersed in a constant temperature 0.005-0.5mol / L phosphoric acid electrolyte for an anodic oxidation reaction. Self-assembled nanopore arrays;

[0128] b) immersing the aluminum sheet after an anodic oxidation reaction in a constant temperature deoxidation layer solution to remove the oxide layer on the surface of the aluminum sheet, leaving an array of na...

Embodiment 3

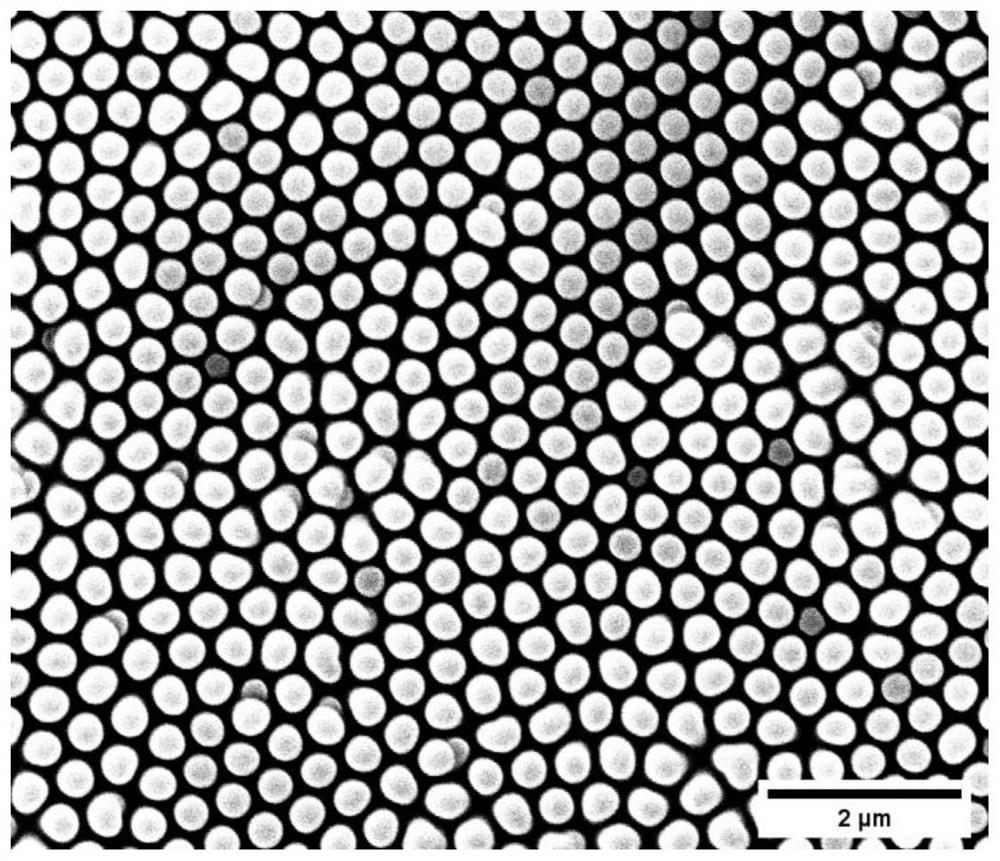

[0142] In this embodiment, a white light LED packaging device with a large curvature surface of an AAO pattern is prepared, and the pattern on the hard template is a pillar array.

[0143] The preparation method for improving the light extraction efficiency of LED packaging devices by using an amorphous photonic structure in this embodiment includes the following steps:

[0144] 1) Preparation of AAO template with amorphous photonic structure with AAO pattern by secondary anodic oxidation method:

[0145] a) After the high-purity aluminum sheet is electrochemically polished, the aluminum sheet is used as an anode and immersed in a constant temperature phosphoric acid electrolyte to perform an anodic oxidation reaction to produce a preliminary self-assembled nanopore array;

[0146] b) immersing the aluminum sheet after an anodic oxidation reaction in a constant temperature deoxidation layer solution to remove the oxide layer on the surface of the aluminum sheet, leaving an arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com