Direct-current droplet generator and preparation method thereof

A generator and droplet technology, applied in the field of power generation technology and sensing, can solve the problems of reducing portability and stability, increasing costs, increasing additional circuit energy loss, etc., to improve water energy utilization, stable output, The effect of output performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention will be described in further detail below with the preparation of DC droplet generator, and this method comprises the steps:

[0030] Step 1: Construction of Solid Hydrophobic Surface

[0031] Select a commercially processed PTFE plate as the material for the required solid surface (11), because the PTFE surface has contact charging characteristics after friction with the droplet, and no pre-charging is required; because the PTFE surface is hydrophobic, no additional treatment is required. Ultrasonic cleaning with acetone for 10 minutes each, then drying at 100°C for later use;

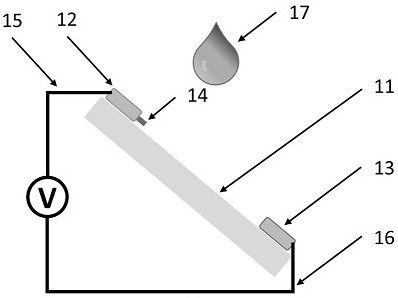

[0032] Step 2: Arranging Electrodes and Assembling the Droplet Generator

[0033] The upper electrode (12) and the lower electrode (13) use copper sheet, aluminum sheet or titanium sheet as the conductive electrode, and a conductive copper wire, titanium wire or platinum wire is attached as the collector needle (14), and the lower electrode (13) In this embodiment, no co...

Embodiment 2

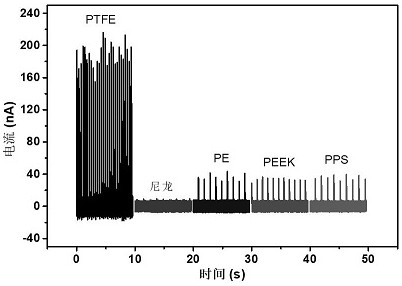

[0038] In order to demonstrate the power generation effect of the DC droplet generator of the present invention, the solid surface 11 of the present invention is a hydrophobic surface of any artificial or natural material, and the following non-limiting examples are used for further detailed description: using PTFE, Nylon, PE, Six materials of PEEK, POM, and PPS were used to manufacture the DC droplet generator of the invention, and the current output performance of the DC droplet generator based on different materials was tested respectively ( image 3 ), further confirming the versatility of the device of the present invention.

Embodiment 3

[0040] The DC droplet generator of the present invention has dual working modes of DC and AC.

[0041] The DC droplet generator of the present invention not only has a kind of DC working mode as mentioned above, but also has another working mode; refer to Figure 4 , when the droplet is in contact with both the collector needle 14 and the lower electrode 13, the output current of the DC droplet generator is DC; when the droplet drop position is adjusted so that the droplet does not touch the collector needle 14 and the upper electrode 12, when only contacting the lower electrode 13, under the condition of keeping other conditions unchanged, the output current of the DC droplet generator becomes AC, which shows that the DC droplet generator of the present invention has dual operation of DC and AC model.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com