Vibrating diaphragm for sound production device and sound production device

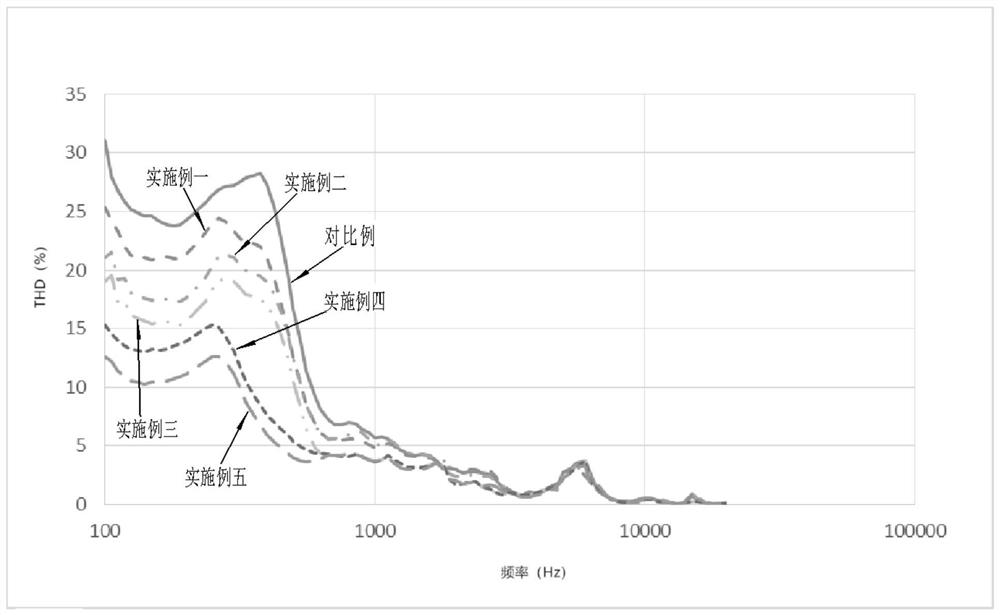

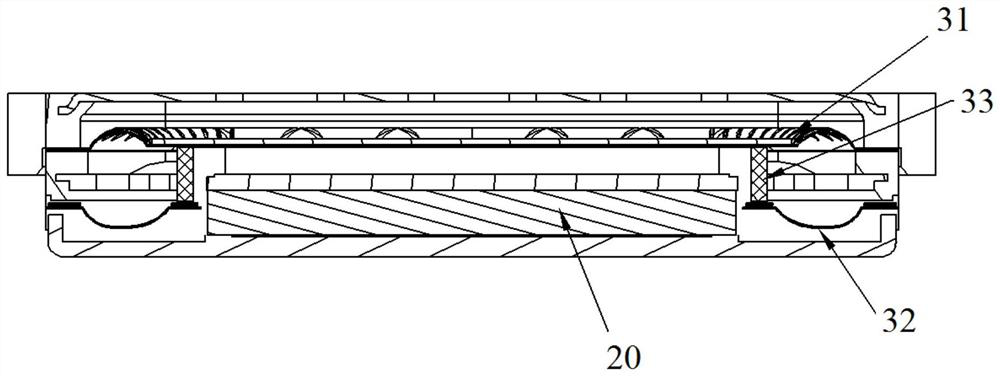

A sound generating device and vibration system technology, applied in the direction of sensors, electrical components, etc., can solve the problems of high total harmonic distortion THD, poor user experience, low diaphragm damping, etc., to achieve high fidelity without abnormal sound, listening Stable and less swaying vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

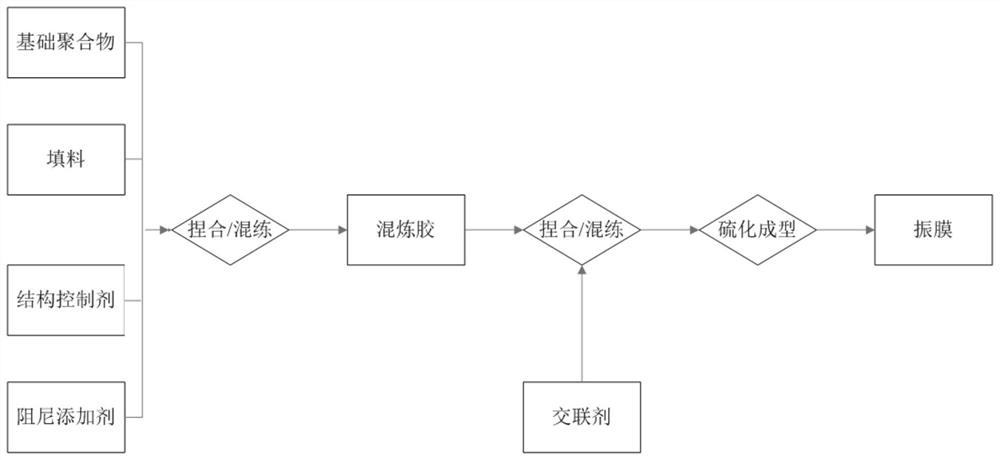

[0082] Polydimethylsiloxane is used as the base polymer, silica is used as the filler, the above-mentioned first modified polysiloxane is added as the damping additive, and hydroxyvinyl silicone oil and hydroxy silicone oil are used as the structure control agent , using 2,5-dimethyl-2,5-di-tert-butylperoxyhexane as a crosslinking agent. Specifically, in terms of mass percentage, according to polydimethylsiloxane 80%, silicon dioxide 9%, damping additive 3%, hydroxyvinyl silicone oil 3%, hydroxy silicone oil 3%, 2,5-dimethyl- 2,5-di-tert-butylperoxyhexane 2%, for batching.

[0083] Mix the basic polymer, filler, structure control agent, and damping additive in an internal mixer at 100°C for 6 hours under reduced pressure to obtain a mixed rubber, which is cooled to room temperature for use; then add a crosslinking agent to the mixed rubber Perform kneading and vulcanization molding at 150° C. to obtain a diaphragm with a thickness of 120 μm.

[0084] After testing, the Shore...

Embodiment 2

[0087] Methyl vinyl polysiloxane is used as the base polymer, silicon dioxide is used as the filler, the above-mentioned first modified polysiloxane is added as the damping additive, and hydroxyvinyl silicone oil is used as the structure control agent. Hydrogen silicone oil, acetylenic alcohol inhibitor and alcohol solution of chloroplatinic acid are used as crosslinking agent. Specifically, in terms of mass percentage, 75% of methyl vinyl polysiloxane, 10% of silicon dioxide, 10% of damping additive, 2% of hydroxyvinyl silicone oil, 2.5% of end-side hydrogen silicone oil and propargyl alcohol inhibitor %, 0.5% alcohol solution of chloroplatinic acid for batching.

[0088] Mix the basic polymer, filler, structure control agent, and damping additive in an internal mixer under reduced pressure at 150°C to obtain a mixed rubber, which is cooled to room temperature for use; then add a crosslinking agent to the mixed rubber for mixing Refined and vulcanized at 180°C to obtain a di...

Embodiment 3

[0092] Methyl vinyl polysiloxane is used as the base polymer, silica is used as the filler, the above-mentioned third modified polysiloxane is added as the damping additive, and hydroxy vinyl silicone oil and hydroxy silicone oil are used as the structure control agent, the alcohol solution containing hydrogen silicone oil, acetylenic alcohol inhibitor and chloroplatinic acid is used as the crosslinking agent. Specifically, in terms of mass percentage, according to methyl vinyl polysiloxane 60%, silicon dioxide 19%, damping additive 15%, hydroxy vinyl silicone oil 2%, hydroxy silicone oil 1%, hydrogen-containing silicone oil and acetylenic alcohol inhibitor A total of 2.5% of the agent and 0.5% of the alcohol solution of chloroplatinic acid were used for batching.

[0093] Mix the basic polymer, filler, structure control agent, and damping additive in an internal mixer under reduced pressure at 120°C to obtain a mixed rubber, which is cooled to room temperature for use; then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com