Nylon flame retardant composite material and preparation method thereof

A technology of flame-retardant composite materials and nylon, which is applied in the field of flame-retardant polyester composite materials, nylon flame-retardant composite materials and their preparation, can solve problems such as easy volatilization, low decomposition temperature, and failure to meet high-temperature nylon processing requirements, and achieve Good flame retardancy, high mechanical strength and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses the preparation of polyphosphonate flame retardant:

[0035] Add 26.04g phosphate methyl diphenyl ester and 31.8g phenolphthalein in the four-neck flask that electromechanical stirrer and vacuum distillation device are housed, then add 0.32g catalyst sodium metaaluminate (catalyst quality is 1% of phenolphthalein quality ), feed nitrogen under stirring, react at 140°C for 1 hour, and react at 180°C for 3 hours. During the reaction, the small molecule phenol produced is separated, and then the reaction is continued for 4 hours under reduced pressure.

[0036] After the reaction, crush the solid crude product obtained after the reaction, fully stir it in hot water at 60°C for 3 hours, then filter it while it is hot, collect the filter cake, and dry it in a vacuum oven at 50°C for 12 hours to obtain a solid product polyphosphonate.

[0037] Concrete synthetic route is as follows:

[0038]

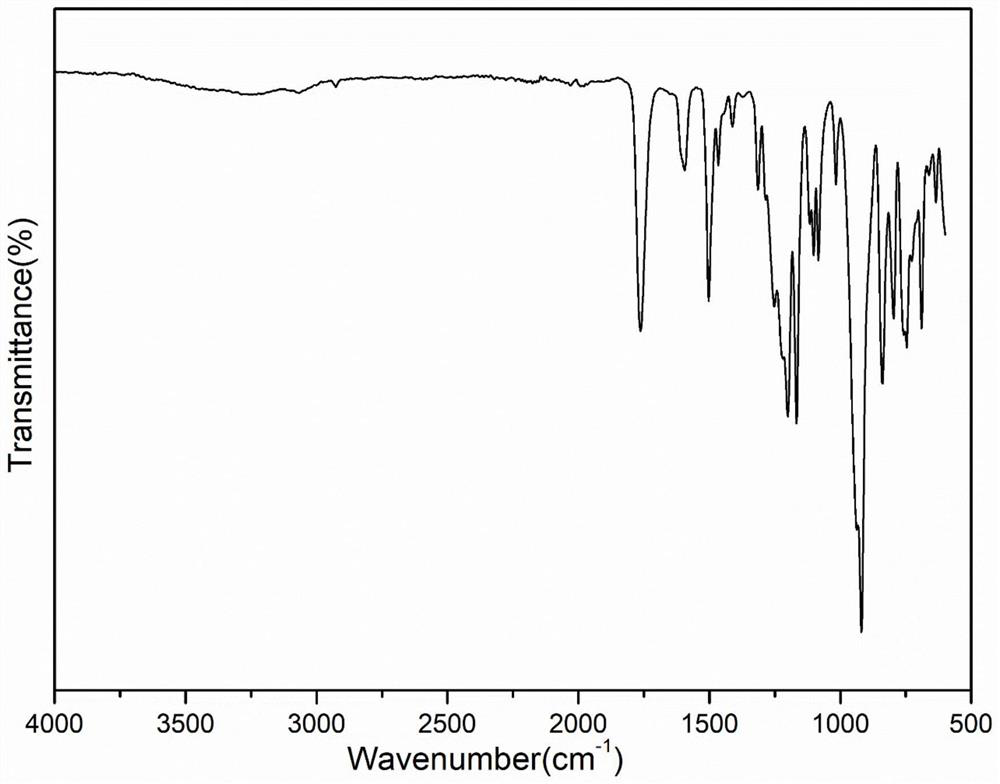

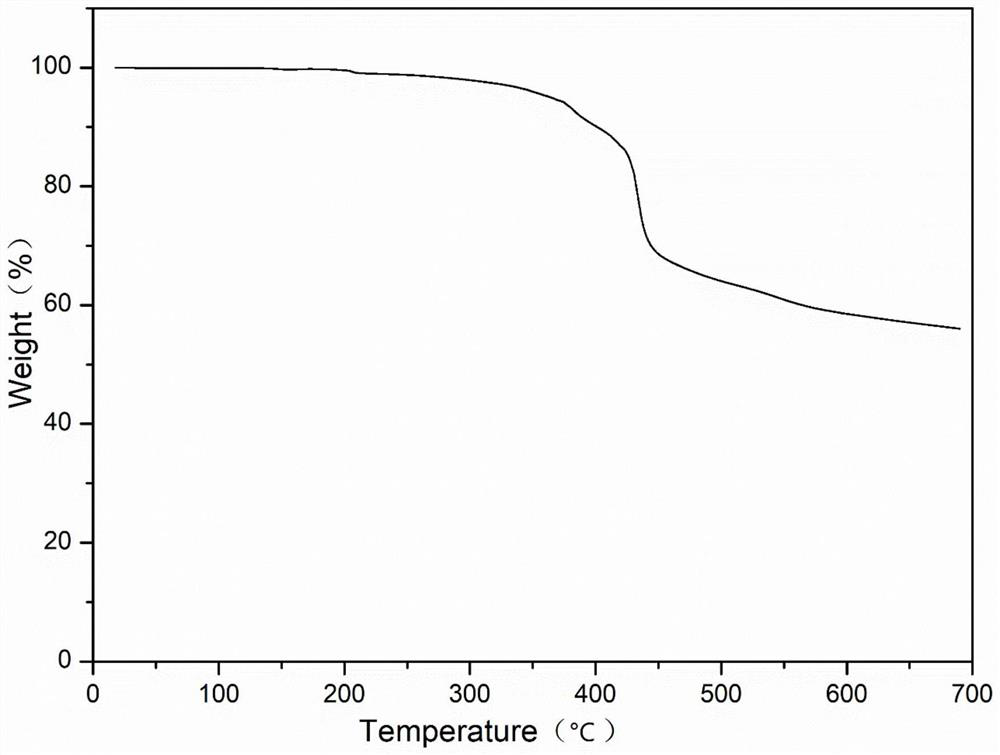

[0039] Wherein, the structural characterization of t...

Embodiment 2

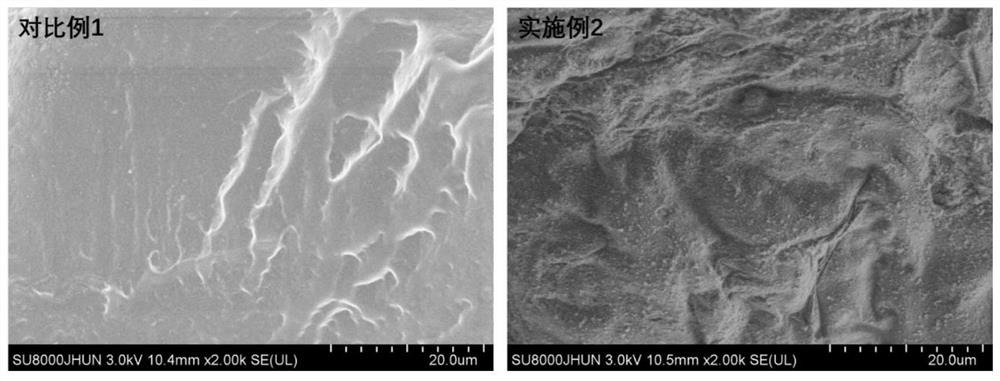

[0043] This embodiment discloses a method for preparing a high-temperature nylon flame-retardant composite material, which includes the following steps:

[0044] (1) Get the polyphosphonate flame retardant 10g that above-mentioned embodiment 1 makes, 0.5g antioxidant and 89.5g nylon 10T resin resin and carry out thorough mixing, obtain mixed base material, then place co-rotating twin-screw extruder In the machine, pellets are processed and granulated, wherein the temperature range of the twin-screw extruder is 300-350° C., and the rotation speed is 160-220 r / min.

[0045] (2) Take the pellets of step (1) and carry out molding processing in an injection molding machine to obtain a composite material, wherein the temperature of the injection molding machine is 300-350°C.

Embodiment 3

[0047] The difference between this embodiment and the above-mentioned embodiment 2 is that the addition amount of the polyphosphonate flame retardant is 15 g, the nylon 10T resin is 84.5 g, and the others remain the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com