Novel environment-friendly automobile exhaust cleaning agent and preparation method thereof

A technology for cleaning automobile exhaust and exhaust gas, which can be used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., and can solve problems such as inability to clean gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

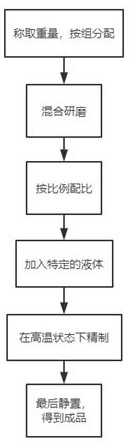

Image

Examples

Embodiment 1

[0026] S1. Weighing and distributing by group: Weigh 100 parts of methanol, 10 parts of n-pentane, 80 parts of polyhydric crude alcohol, 40 parts of ricinoleic acid, 5 parts of methyl acetate, 1 part of fatty alcohol and 2 parts of lauryl alcohol, mix it together;

[0027] S2. Mixed grinding: fully grind the items taken in S1 to make full contact between each material;

[0028] S3. Proportional ratio: mix 0.01 part of metal corrosion inhibitor, 1 part of cosolvent and 0.05 part of flame retardant according to 1:2:1 to form a specific solution;

[0029] S4. Adding a specific liquid: fully mix the liquid according to S3, and then fully mix the mixed liquid with the substance in step S2 to make them fully contact;

[0030] S5, refining at high temperature: first stir at normal temperature and pressure for 2h to obtain the mixed solution, then refine the mixed solution at 100°C;

[0031] S6. Finally, let it stand still to obtain the finished product: after being refined at high ...

Embodiment 2

[0033] S1. Weighing and distributing by group: Weighing 125 parts of methanol, 15 parts of n-pentane, 90 parts of polyhydric crude alcohol, 50 parts of ricinoleic acid, 10 parts of methyl acetate, 3 parts of fatty alcohol and 5 parts of lauryl alcohol, mix it together;

[0034] S2. Mixed grinding: fully grind the items taken in S1 to make full contact between each material;

[0035] S3. Proportional ratio: mix 1 part of metal corrosion inhibitor, 3 parts of cosolvent and 2 parts of flame retardant according to 1:3:2 to form a specific solution;

[0036] S4. Adding a specific liquid: fully mix the liquid according to S3, and then fully mix the mixed liquid with the substance in step S2 to make them fully contact;

[0037] S5, refining at high temperature: first stir at normal temperature and pressure for 2.5h to obtain the mixed solution, then refine the mixed solution at 120°C;

[0038] S6. Finally, let it stand still to obtain the finished product: after being refined at hi...

Embodiment 3

[0040] S1. Weighing and distributing by group: Weighing 140 parts of methanol, 20 parts of n-pentane, 100 parts of polyhydric crude alcohol, 60 parts of ricinoleic acid, 15 parts of methyl acetate, 5 parts of fatty alcohol and 10 parts of lauryl alcohol, mix it together;

[0041] S2. Mixed grinding: fully grind the items taken in S1 to make full contact between each material;

[0042] S3. Proportional ratio: mix 1.5 parts of metal corrosion inhibitor, 5 parts of cosolvent and 3 parts of flame retardant according to 3:10:6 to form a specific solution;

[0043] S4. Adding a specific liquid: fully mix the liquid according to S3, and then fully mix the mixed liquid with the substance in step S2 to make them fully contact;

[0044] S5, refining at high temperature: first stirring at normal temperature and pressure for 3h to obtain the mixed solution, then refining the mixed solution at 140°C;

[0045] S6. Finally, let it stand still to obtain the finished product: after being ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com