Continuous production line of small-canister Jinjunmei black tea

A production line and technology of Junmei, which is applied to tea processing before extraction, chemical instruments and methods, food preservation, etc., can solve the problems of high production cost, unstable tea quality, continuous and low degree of automation of Jinjunmei black tea processing, etc. , to achieve the effect of good quality, smooth tea making process and high tea making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

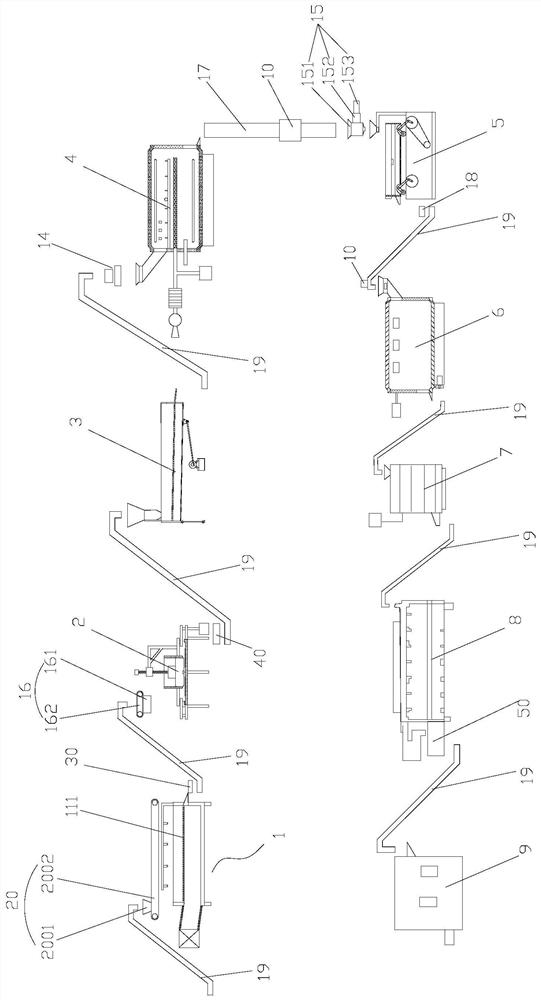

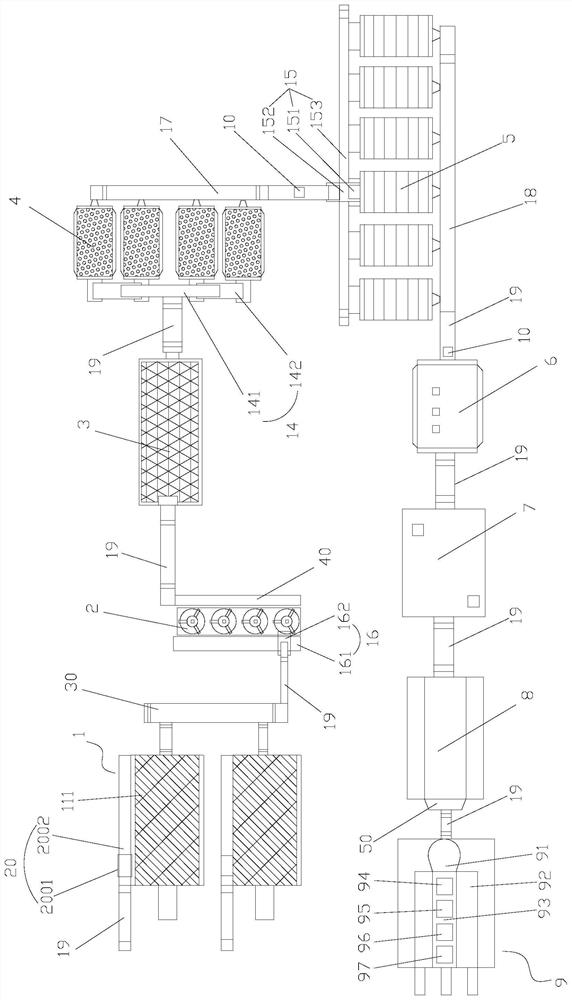

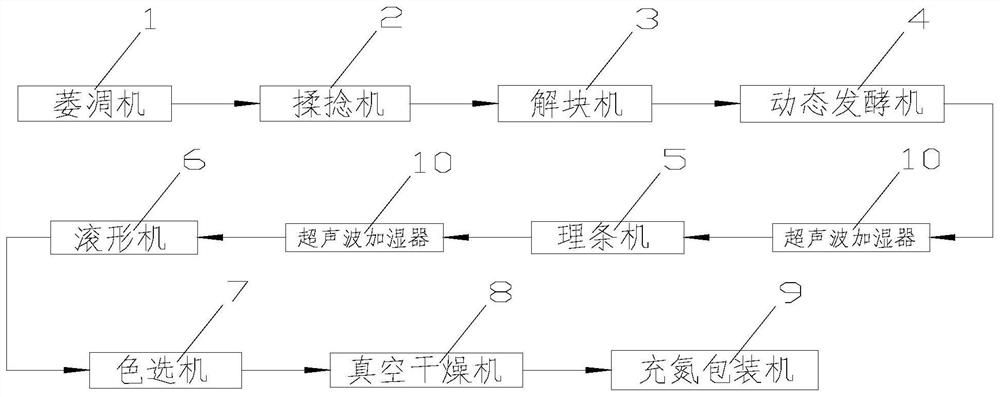

[0028] Example 1, such as Figures 1 to 9 As shown, a continuous production line for small cans of Jinjunmei black tea includes a kneading unit consisting of 2 withering machines 1 and 4 kneading machines 2 arranged side by side, a deblocking machine 3, and 4 dynamic fermentation machines 4 The fermentation unit that is formed, the shaping unit that is made up of 6 striping machines 5, 1 rolling machine 6, the removing machine that is made up of 1 color sorting machine 7, 1 vacuum drier 8 and 1 nitrogen-filling packaging machine 9 Miscellaneous drying and packaging unit, the specific connection relationship between each equipment is as follows:

[0029] Above the two withering machines 1, a mobile conveyor 20 is respectively arranged, and the mobile conveyor 20 includes a conveyor frame 2001 that moves back and forth and a first rotary conveyor belt 2002 arranged on it; to the top of the first rotary conveyor belt 2002, and then move back and forth along the tank body of the ...

Embodiment 2

[0054] Embodiment 2: the preparation method of extra-grade small can Jinjunmei black tea comprises the following steps:

[0055] 1) Picking fresh leaves: picking a single bud or a fresh leaf that has just unfolded;

[0056] 2) Withering of fresh leaves: spread the fresh leaves in the withering trough with a thickness of 7-8cm, usually wither indoors for 1-1.2h, and then use "green light" with a wavelength of 495-530nm to set withering The temperature is 34-35°C, and the light is withered for 1.5-1.8h; finally, low-temperature withering is carried out without light, and the withering temperature is set at 24-25°C, and the withering time is 2.5-2.8h, so that the water content of the buds and leaves is controlled at 53-54% between, the red-yellow rate of buds and leaves is controlled between 23-24%;

[0057] 3) Kneading: transport the withered buds and leaves to the kneading machine and knead for 8 minutes; knead without pressure for 3 minutes, pressurize 1 / 4 for 3 minutes, and ...

Embodiment 3

[0065] Embodiment 3: the preparation method of one-level small can Jin Junmei black tea, comprises the following steps:

[0066] 1) Picking fresh leaves: picking fresh leaves with one bud and one leaf;

[0067] 2) Withering of fresh leaves: spread the fresh leaves in the withering tank with a thickness of 5-6cm, wither at room temperature for 1.5-1.8h, use the same "green light", set the withering temperature to 34-36°C , light and heat withering for 1.8-2h; finally, low-temperature withering without light, set the withering temperature at 24-26°C, and the withering time at 2.8-3h, so that the water content of buds and leaves is controlled between 54-55%, and the water content of buds and leaves The red-yellow rate is controlled between 21-22%;

[0068] 3) Kneading: transfer the withered buds and leaves to a kneading machine for 10 minutes; knead without pressure for 3 minutes, pressurize 1 / 4 for 5 minutes, and decompress and knead for 2 minutes.

[0069] 4) Deblocking: tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com