Preparation method, product and application of room-temperature phosphorescent hydrogel

A room temperature phosphorescence and hydrogel technology, applied in chemical instruments and methods, luminescent materials, luminescent coatings, etc., can solve problems such as fracture, phase separation, uneven luminescence, etc., achieve simple synthesis routes, improve RTP performance, and improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

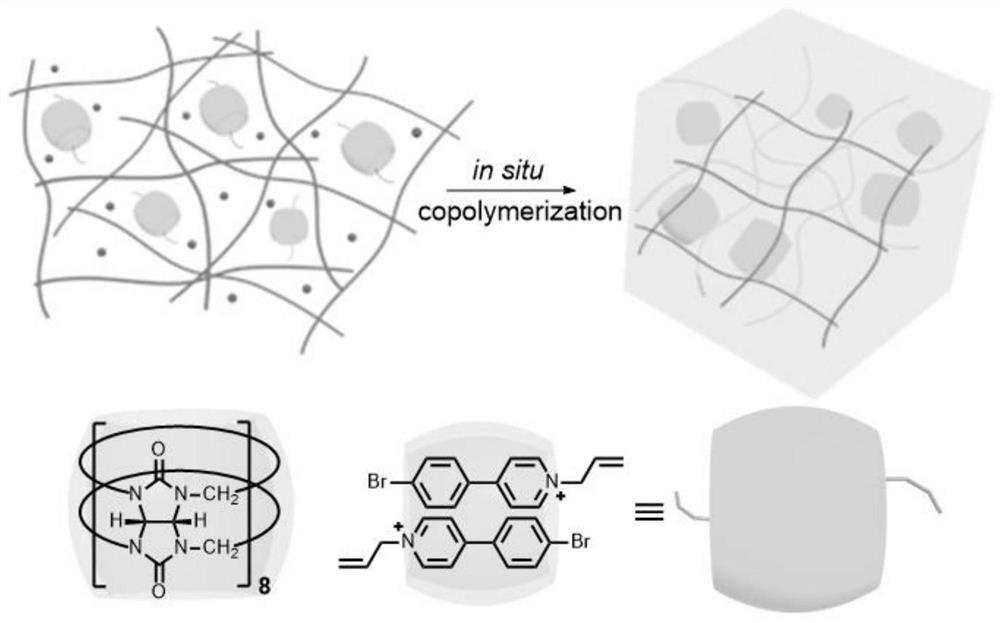

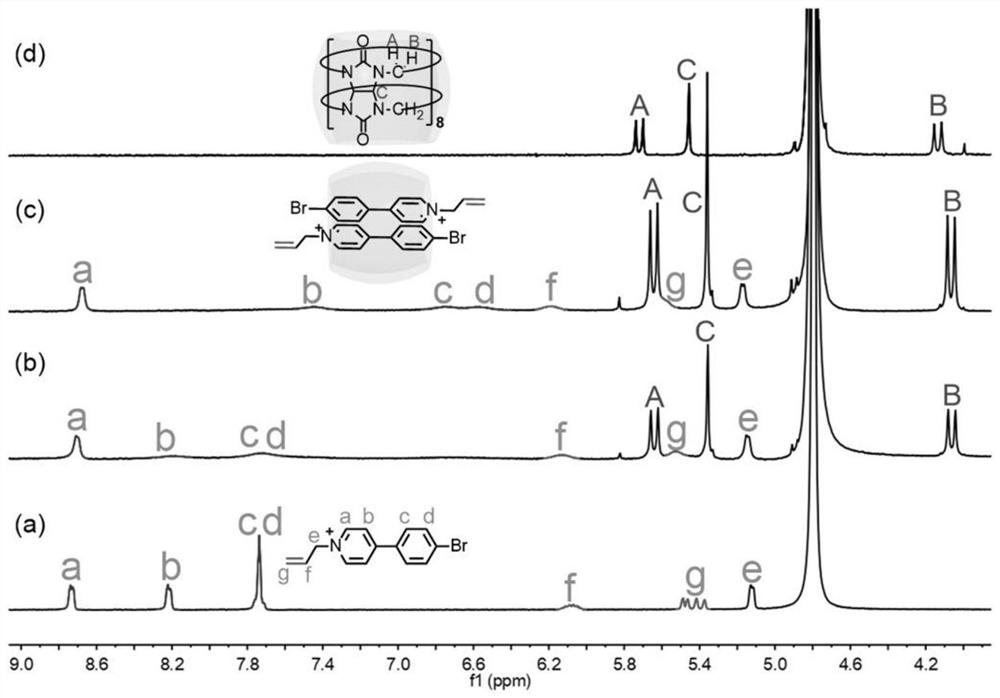

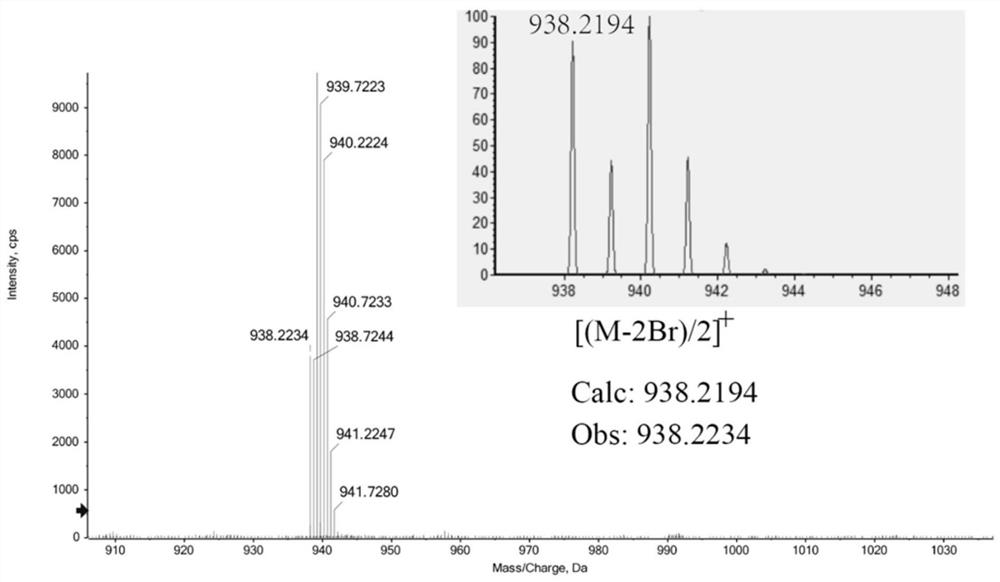

[0053] Step 1, add CB[8] and ABP into water at a molar ratio of 1:2, dissolve it under ultrasonic conditions at 50°C to obtain supramolecular clathrate (CB[8] / ABP) solution A; Add acrylamide to A to obtain monomer solution B; wherein, the concentration of CB[8] / ABP in solution B is 37.5 mM and the concentration of acrylamide is 5M in terms of CB[8].

[0054] Step 2. Dissolve PVA-124 in water at 90°C. After the PVA-124 is completely dissolved, let it stand at room temperature for 30 minutes to obtain solution C; the mass concentration of PVA-124 in solution C is 10%.

[0055] Step 3, dissolving phenyl (2,4,6-trimethylbenzoyl) lithium phosphate (LAP) in 0.1M, pH=9.5 borate buffer solution to prepare initiator solution D; LAP The concentration in Solution D was 86 mM.

[0056] Step 4, all the above solutions were washed with N 2 Bubble for 10 minutes to expel the oxygen in the solution, then mix solution B and solution D at a volume ratio of 2:1, and use N 2 Bubble for 10min, ...

Embodiment 2

[0070] The difference from Example 1 is that the temperature in step 1 is 40°C, the concentration of acrylamide is 4M, and the pH of the borate buffer solution in step 3 is 9.

[0071] Result: The room temperature phosphorescent hydrogel prepared in this example was tested the same as in Example 1, and the result was similar to that of Example 1. The phosphorescence lifetime of the hydrogel reached about 5.0 ms, and the phosphorescence quantum yield was about 9.0%. The tensile strength reaches 105kPa, the storage modulus G′ is 83kPa, the loss modulus G″ is 14kPa, the storage modulus G′ after self-repair is 80kPa, the loss modulus G″ is 13kPa, and it can withstand 158% deformation. And it has excellent self-repair performance, and can be prepared into a self-supporting film, which has good phosphorescent properties and self-repair behavior.

Embodiment 3

[0073] The difference from Example 1 is that the temperature in step 1 is 60°C, the concentration of acrylamide is 6.5M, and the pH of the borate buffer solution in step 3 is 10.

[0074]Result: The room temperature phosphorescence hydrogel prepared in this example was tested the same as Example 1, and the result was similar to Example 1. The phosphorescence lifetime of the hydrogel reached about 4.9ms, and the phosphorescence quantum yield was about 8.9%. The tensile strength reaches 103kPa, the storage modulus G′ is 82kPa, the loss modulus G″ is 13kPa, the storage modulus G′ after self-repair is 80kPa, the loss modulus G″ is 12kPa, and it can withstand 157% deformation. And it has excellent self-repair performance, and can be prepared into a self-supporting film, which has good phosphorescent properties and self-repair behavior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com