Nano antibacterial master batch

A kind of antibacterial masterbatch and nanotechnology, which is applied in the field of antibacterial agents, can solve the problems that the surface of graphene has not been modified, cannot be applied in the field of food packaging, and nanomaterials are easy to agglomerate, so as to achieve good dispersion uniformity, reduce viscosity and migration of products Effect of high risk and product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

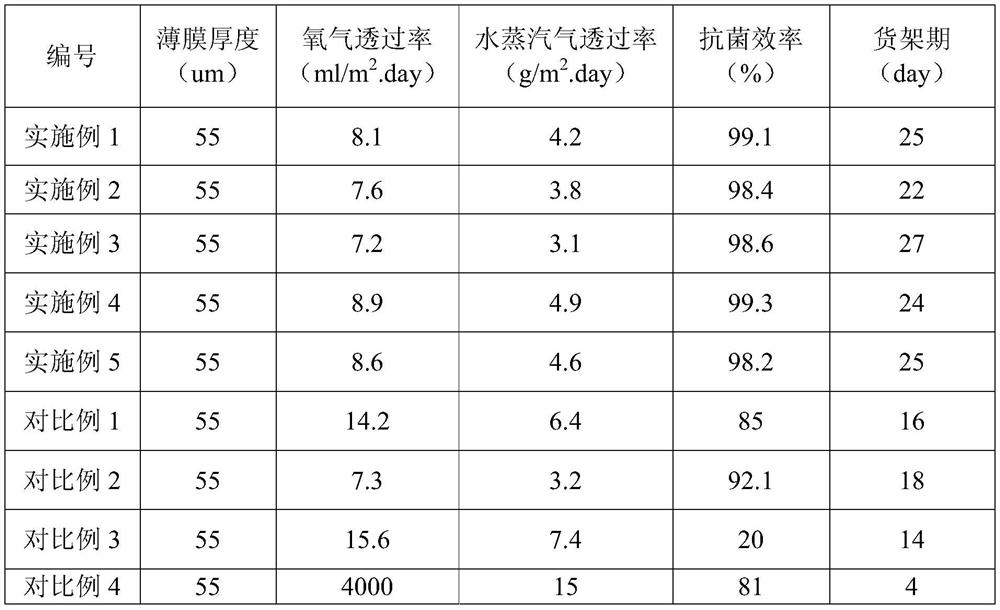

Examples

Embodiment 1

[0035] A nano antibacterial masterbatch, prepared from the following materials and according to the following method, graphene oxide GO, deionized water, tetraethoxysilane, ammonia water, pyrrolidone solution, sodium borohydride solution, AgNO3 solution, liquid aluminate Coupling agent PN-827 and LDPE powder, the preparation method is as follows:

[0036] (1) Preparation of SiO 2 / GO Nanomaterials

[0037] In a 5L reaction flask, weigh 1.2g of GO with an average diameter of 400nm and add it into deionized water to form a suspension with a concentration of 0.3g / L, ultrasonically disperse for 0.5h (ultrasonic frequency is 10000Hz), add 0.3g of tetraethoxy base silane, then add ammonia water to adjust the pH of the solution to 8, then seal it with parafilm and continue to stir for 0.5h (stirring speed is 80rpm), filter to obtain 1.31gSiO 2 / GO nano-powder and filtrate, the nano-powder was washed with deionized water, centrifuged and dried to obtain 1.28gSiO 2 / GO nanomaterials...

Embodiment 2

[0045] A nano antibacterial masterbatch, prepared from the following materials and according to the following method, graphene oxide GO, deionized water, tetraethoxysilane, ammonia water, pyrrolidone solution, sodium borohydride solution, AgNO3 solution, liquid aluminate Coupling agent PN-827 and LDPE powder, the preparation method is as follows:

[0046] (1) Preparation of SiO 2 / GO Nanomaterials

[0047] In a 5L reaction flask, weigh 1.6g of GO with an average diameter of 430nm and add it into deionized water to form a suspension with a concentration of 0.4g / L, ultrasonically disperse for 0.3h (ultrasonic frequency is 11000Hz), add 0.32g of tetraethoxy base silane, then add ammonia water to adjust the pH of the solution to 8.5, then seal it with parafilm and continue to stir for 1h (stirring speed is 90rpm), and filter to obtain 1.71gSiO 2 / GO nano-powder and filtrate, the nano-powder was washed with deionized water, centrifuged and dried to obtain 1.62gSiO 2 / GO nanomate...

Embodiment 3

[0055] A nano antibacterial masterbatch, prepared from the following materials and according to the following method, graphene oxide GO, deionized water, tetraethoxysilane, ammonia water, pyrrolidone solution, sodium borohydride solution, AgNO3 solution, liquid aluminate Coupling agent PN-827 and LDPE powder, the preparation method is as follows:

[0056] (1) Preparation of SiO 2 / GO Nanomaterials

[0057] In a 5L reaction flask, weigh 2g of GO with an average diameter of 420nm and add it into deionized water to form a suspension with a concentration of 0.5g / L, ultrasonically disperse for 0.5h (ultrasonic frequency is 12000Hz), add 0.37g of tetraethoxy Silane, then add ammonia water to adjust the pH of the solution to 9.5, then seal it with parafilm and continue to stir for 2h (stirring speed is 87rpm), filter to obtain 2.3gSiO 2 / GO nano-powder and filtrate, the nano-powder was washed with deionized water, centrifuged and dried to obtain 2.1gSiO 2 / GO nanomaterials.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com