Semiconductor wafer cutting device

A cutting device and semiconductor technology, which is applied to fine working devices, cleaning methods using gas flow, working accessories, etc., can solve the problems of diamond graphitization, affecting the service life of the cutting disc, and the cutting disc being easily burnt and falling off. To achieve the effect of ensuring cleanliness and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

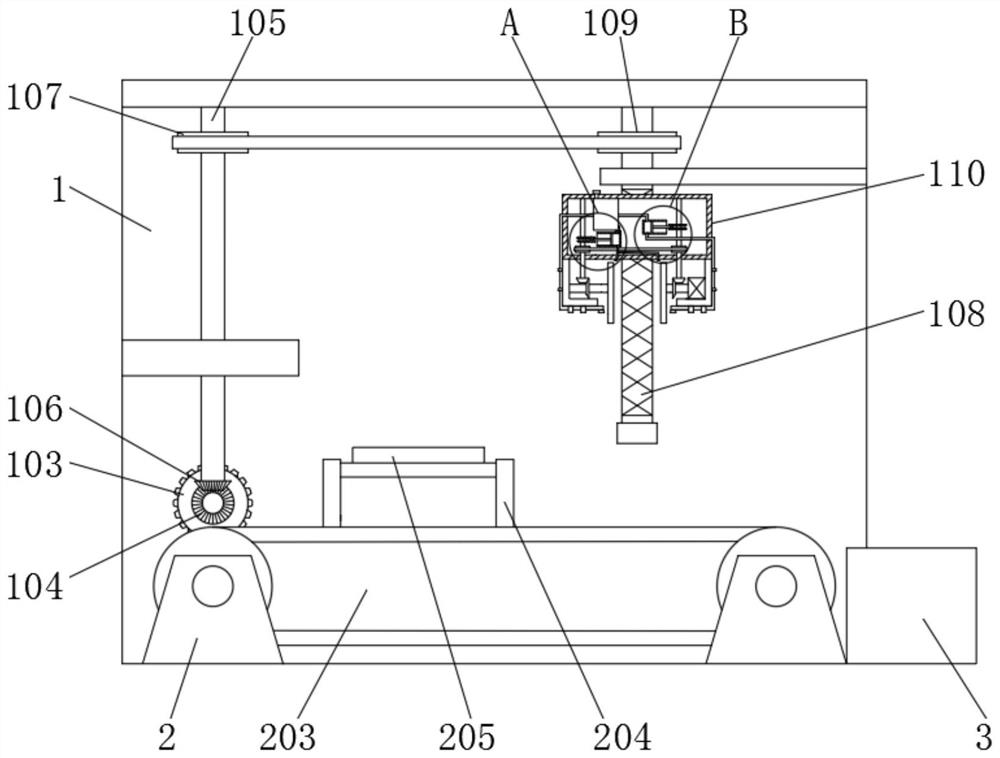

[0032] refer to Figure 1-7, a semiconductor wafer cutting device, comprising a vertical plate 1, a fixed plate 2 and a silicon body 205, the vertical plate 1 is fixedly connected with a first motor 102, the output shaft of the first motor 102 is connected with a first bevel gear 104, the vertical The plate 1 is rotatably connected with a first rotating shaft 105, the bottom of the first rotating shaft 105 is fixedly connected with a second bevel gear 106 meshing with the first bevel gear 104, and the side wall of the riser 1 is rotatably connected with a reciprocating screw rod 108. A rotating shaft 105 and the reciprocating screw mandrel 108 are connected by a first belt, the reciprocating screw mandrel 108 is threadedly connected with a slide box 110, the bottom of the slide box 110 is provided with a cutting mechanism, and the bottom of the slide box 110 is provided with a drive cutting mechanism. The second motor 111 is equipped with a cooling mechanism and a cleaning mec...

Embodiment 2

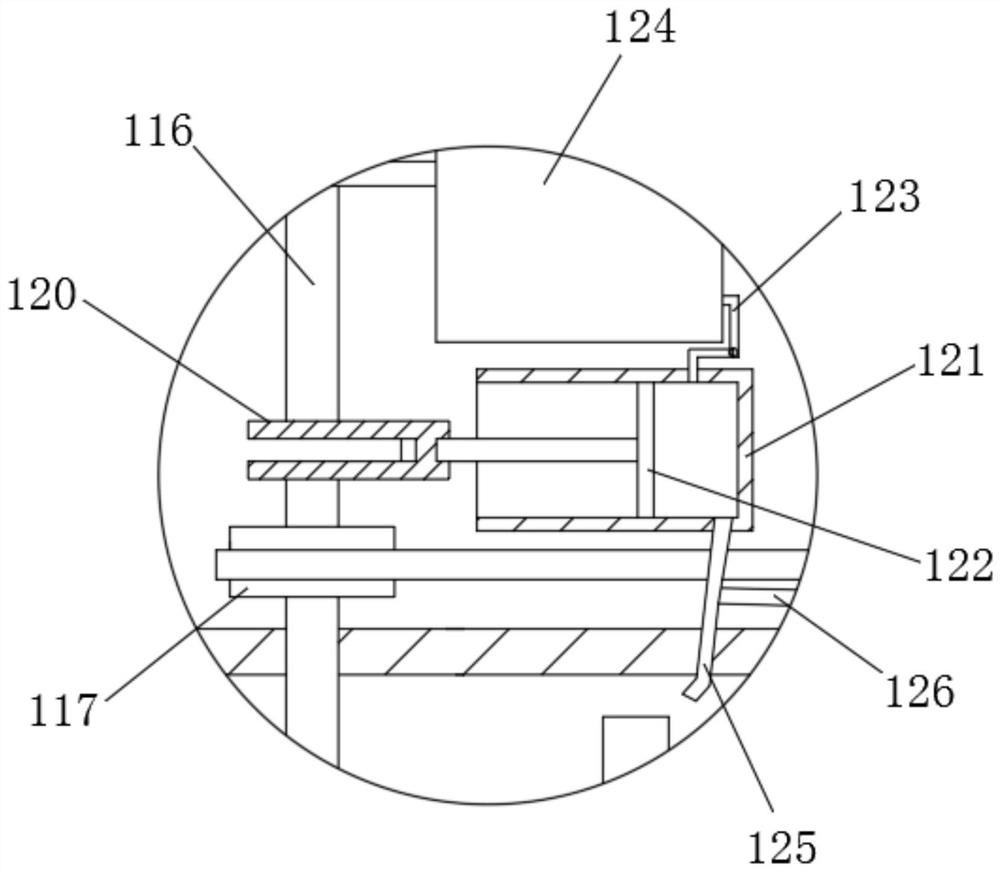

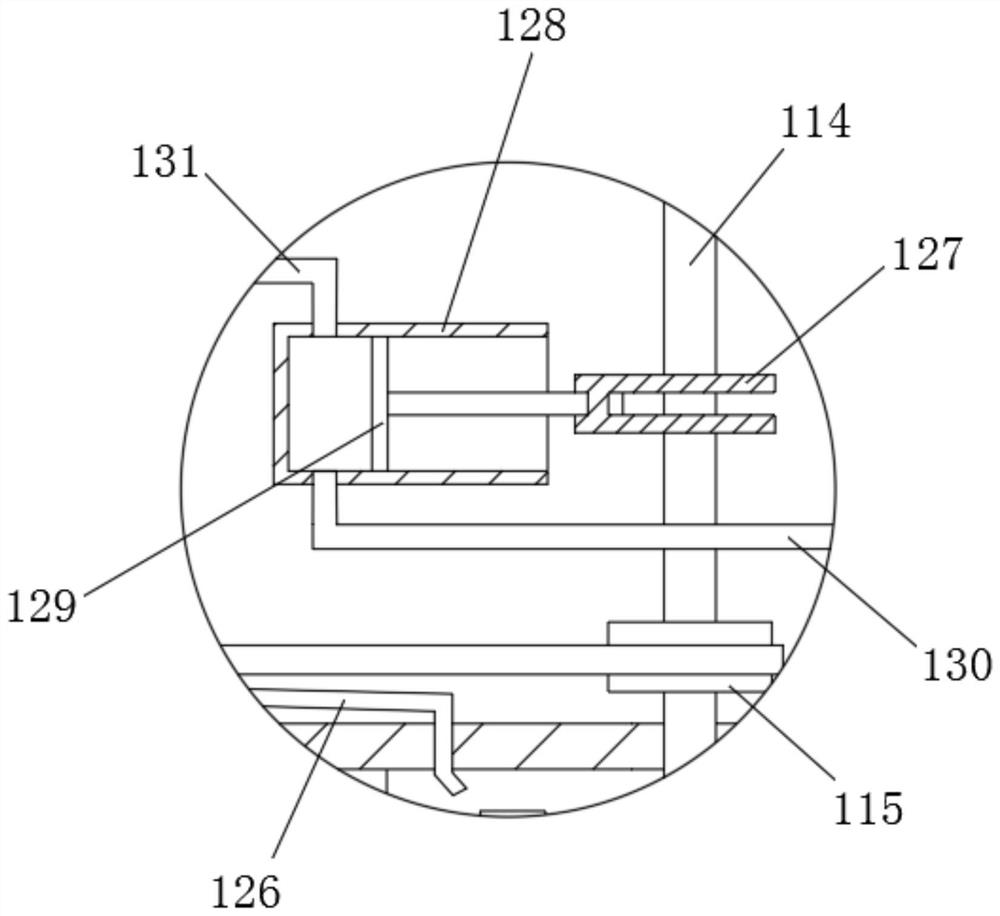

[0037] refer to figure 1 , Figure 4 with Figure 5 , is basically the same as Embodiment 1, furthermore, in order to cut the silicon body, the cutting mechanism includes a first cutting disc 113 and a second cutting disc 119, and the output end of the second motor 111 is fixedly connected with a second rotating shaft 112, The first cutting disc 113 is fixedly connected to the second rotating shaft 112, the third rotating shaft 114 and the fourth rotating shaft 116 are respectively connected to rotate in the slide box 110, and a bevel gear set 1 is connected between the third rotating shaft 114 and the second rotating shaft 112, The third pulley 115 is fixedly connected on the third rotating shaft 114, the fourth pulley 117 is fixedly connected on the fourth rotating shaft 116, the second belt is connected between the third pulley 115 and the fourth pulley 117, and the slide box 110 The bottom of the bottom is rotatably connected with a fifth rotating shaft 118, the second c...

Embodiment 3

[0043] refer to figure 1 , figure 2 with Figure 5 , is basically the same as Embodiment 1, furthermore, in order to lower the temperature of the cutting mechanism, the cooling mechanism includes a coolant tank 124, a first crankshaft 120, a first connection box 121 and a first piston 122, a coolant tank 124 and a first piston 122 A connecting box 121 is fixedly connected in the slide box 110, the first piston 122 is slidably connected in the first connecting box 121, the first crankshaft 120 is fixedly connected on the fourth rotating shaft 116, and the outer wall of the first crankshaft 120 is rotatably connected with a second A connecting rod, the end of the first connecting rod away from the first crankshaft 120 is connected to the side wall of the first piston 122 in rotation, and a liquid suction pipe 123 is connected between the first connection box 121 and the coolant tank 124, and the liquid suction pipe 123 A one-way valve is provided, the side wall of the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com