Belt type squeezing filter press

A filter press and press roller technology, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of sludge not being allowed to be shipped out, sludge cannot be received, etc., to achieve savings Outbound transportation costs, reducing comprehensive processing costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

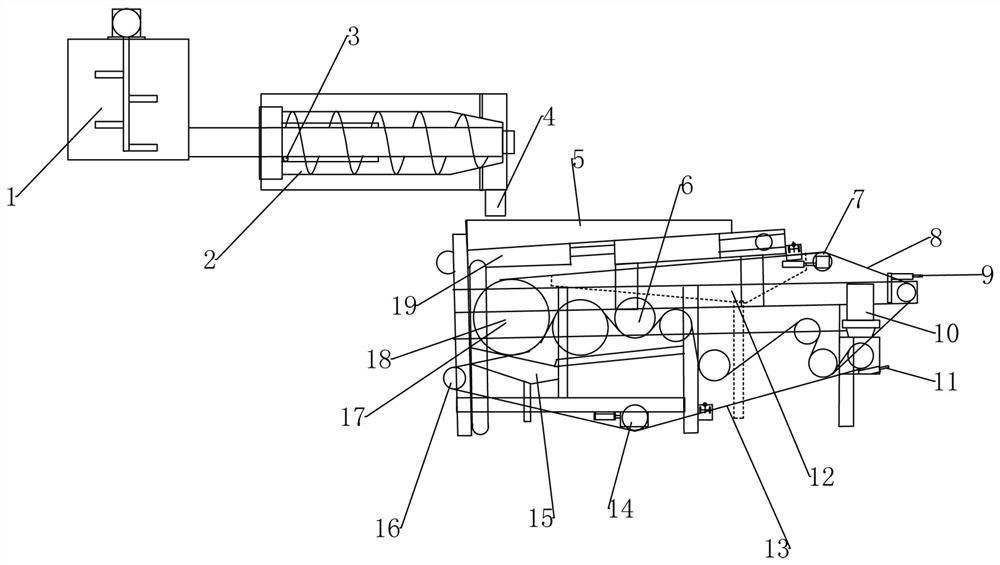

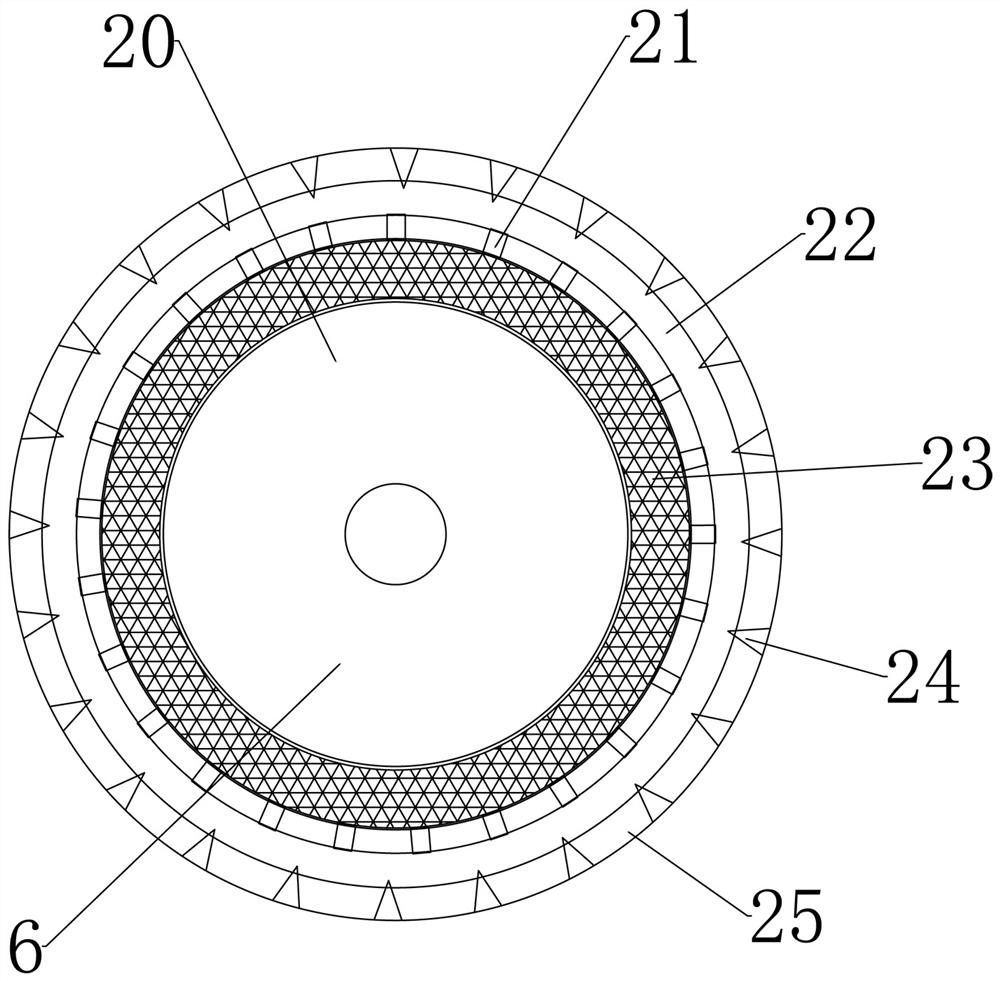

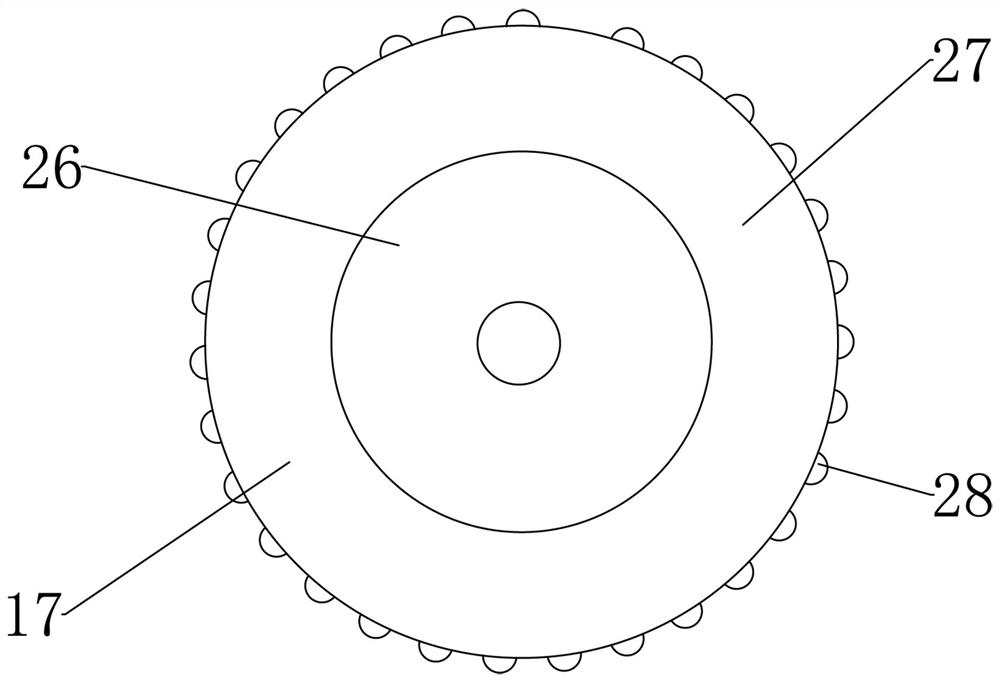

[0021] Such as Figure 1-Figure 4 As shown, a belt press filter press includes a conditioning box 1, a drum centrifuge 2 and a filter press, the outlet of the conditioning box 1 is connected to the inlet of the drum centrifuge 2, and the drum centrifuge The mud discharge port 4 of 2 is located above the material distribution device 5 of the filter press, and the material distribution device 5 is located on the top of the frame. The upper liquid receiving plate 19 and the tensioning device are arranged below the material distribution device 5, and the tensioning device is connected with the upward adjustment roller 7. , the upper adjustment roller 7 is connected with the upper filter belt 8, and the upper filter belt 8 is set on the upper filter belt idler assembly 18, and the upper filter belt idler assembly 18 overlaps with the part of the lower filter belt idler assembly 16. The lower filter belt 13 is arranged on the filter belt idler assembly 16, the upper scraper 9 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com