A kind of industrial catalytic method of synthesizing nitro-substituted compound

An industrial and catalyst technology, applied in the field of chemical intermediate synthesis, can solve the problems of cumbersome crystallization treatment process or post-treatment steps, difficult to adapt to large-scale industrial production, unsatisfactory product yield and other problems, and achieves efficient catalytic synthesis, Broad industrialization prospects and technological transformation value, the effect of reducing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

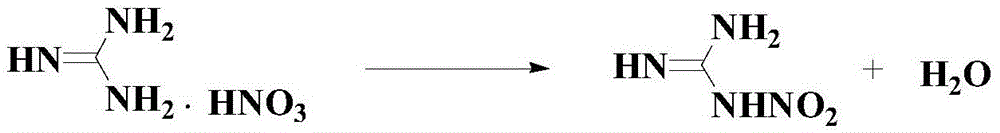

Image

Examples

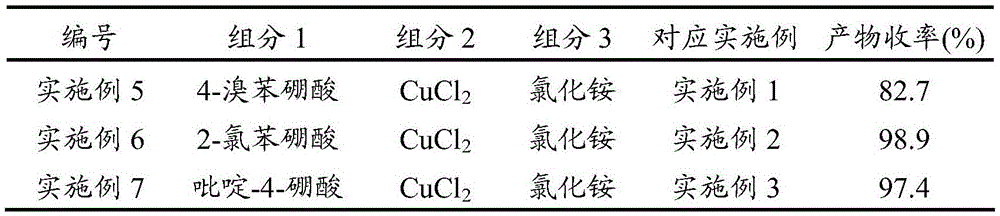

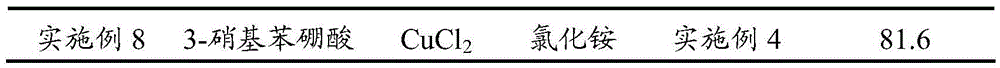

preparation example 1

[0030] Weigh thiophene-3-boronic acid and CuCl according to the molar ratio of 1:1:1 2 And each component of ammonium chloride, it is placed in the mortar and grinds and mixes evenly, promptly obtains the catalyst that adopts in the following all specific embodiments of the present invention.

Embodiment 1

[0032] Add 1000g of nitric acid with a mass concentration of 35% to the reaction kettle with cooling water, maintain the temperature at 5-10°C, add 500g of guanidine nitrate in turn, add 25g of catalyst under stirring, and then add 25g of crown ether 18-crown- 6. Raise the temperature to 28°C, continue to stir the reaction for 30 minutes, and the speed of the stirrer is 200r / min, then pour the reaction mixture into ice water, and a large amount of solids are precipitated. After filtering and washing, the pure product of nitroguanidine, nitroguanidine can be obtained. The base guanidine yield was 98.8%, and the purity was 98.7% (HPLC).

Embodiment 2

[0034]Add 1200g of nitric acid with a mass concentration of 30% to the reaction kettle with cooling water, maintain the temperature at 5-10°C, add 500g of guanidine nitrate in turn, add 25g of catalyst under stirring, and then add 10g of crown ether 15-crown- 5. Raise the temperature to 32°C, continue to stir the reaction for 40 minutes, the stirrer speed is 300r / min, then pour the reaction mixture into ice water, a large amount of solids are precipitated, after filtering and washing, the pure nitroguanidine, nitroguanidine can be obtained. The yield of guanidine was 99.4%, and the purity was 98.9% (HPLC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com