High-performance anti-freezing concrete and preparation method thereof

A concrete, high-performance technology, applied in the field of concrete, can solve the problems of concrete cracking and increased dry shrinkage, and achieve the effects of reducing cracks, improving strength, and improving frost resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

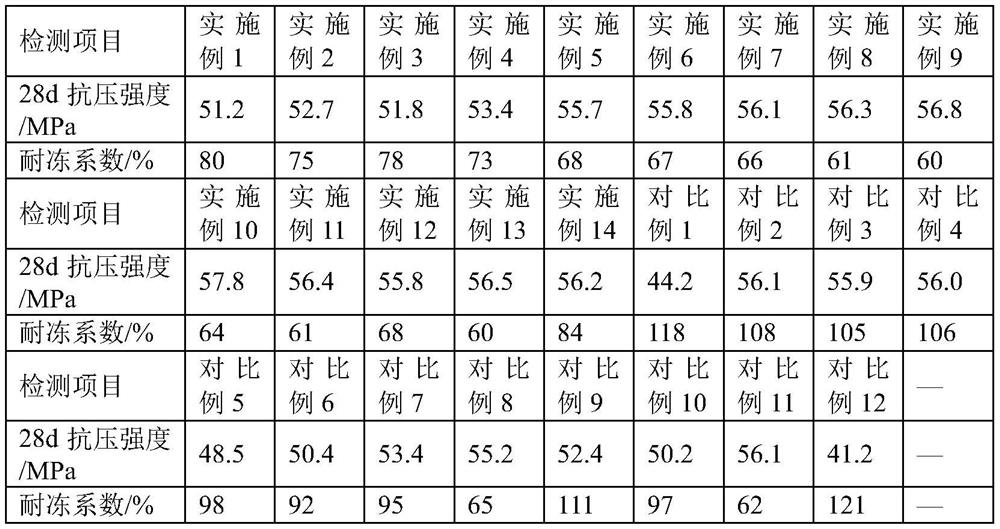

Examples

Embodiment 1

[0046]A preparation method for high-performance frost-resistant concrete, comprising the following steps:

[0047] Preparation of water-colloid dispersion A: Take 25kg of lithium magnesium silicate and 48kg of water and mix and stir at 35°C for 30 minutes to obtain water-colloid dispersion A;

[0048] Mixture preparation: Stir 200kg cement, 70kg mineral powder, 800kg crushed stone, 500kg sand and 60kg fly ash for 10 minutes, then add 30kg polypropylene fiber, stir for 5 minutes, add 2kg water reducer and 48kg water, stir for 15 minutes, and get a mixture material;

[0049] Concrete preparation: Add the water-gel dispersion A prepared in the preparation step of the water-gel dispersion A and 24kg of water to the mixture, stir for 20 minutes, and finally add 15kg of polyvinylidene chloride copolymer emulsion, and stir for 15 minutes to obtain the product.

[0050] Among them, the water reducer is polycarboxylate water reducer.

Embodiment 2

[0052] A preparation method for high-performance frost-resistant concrete, comprising the following steps:

[0053] Preparation of water-colloid dispersion A: Take 32kg of lithium magnesium silicate and 54kg of water and mix and stir at 40°C for 25 minutes to obtain water-colloid dispersion A;

[0054] Mixture preparation: Stir 250kg cement, 80kg mineral powder, 900kg gravel, 600kg sand and 70kg fly ash for 10 minutes, then add 40kg polypropylene fiber, stir for 5 minutes, add 3kg water reducer and 54kg water, stir for 20 minutes, and get a mixed material material;

[0055] Concrete preparation: Add the water-gel dispersion A prepared in the preparation step of the water-gel dispersion A and 27kg of water to the mixture, stir for 25 minutes, and finally add 20kg of polyvinylidene chloride copolymer emulsion, and stir for 20 minutes to obtain the product.

[0056] Among them, the water reducer is polycarboxylate water reducer.

Embodiment 3

[0058] A preparation method for high-performance frost-resistant concrete, comprising the following steps:

[0059] Preparation of water-colloid dispersion A: Take 40kg of lithium magnesium silicate and 60kg of water and mix and stir at 45°C for 20 minutes to obtain water-colloid dispersion A;

[0060] Mixture preparation: 300kg of cement, 90kg of mineral powder, 1000kg of gravel, 700kg of sand and 75kg of fly ash were stirred for 15 minutes, then 50kg of polypropylene fiber was added, stirred for 10 minutes, 5kg of water reducing agent and 60kg of water were added, and stirred for 20 minutes to obtain a mixture material;

[0061] Concrete preparation: add the water-gel dispersion A prepared in the preparation step of the water-gel dispersion A and 30kg of water to the mixture, stir for 30 minutes, and finally add 25kg of polyvinylidene chloride copolymer emulsion, and stir for 20 minutes to obtain the product.

[0062] Among them, the water reducer is polycarboxylate water r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com