Ultraviolet-curing structural adhesive composition and application thereof

A technology of curing structure and ultraviolet light, applied in the field of structural adhesive, can solve the problems of affecting the visual effect of transparent state, poor flexibility, and high glass transition temperature, and achieve thin film, good shape retention, and excellent adhesion of dimming products. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

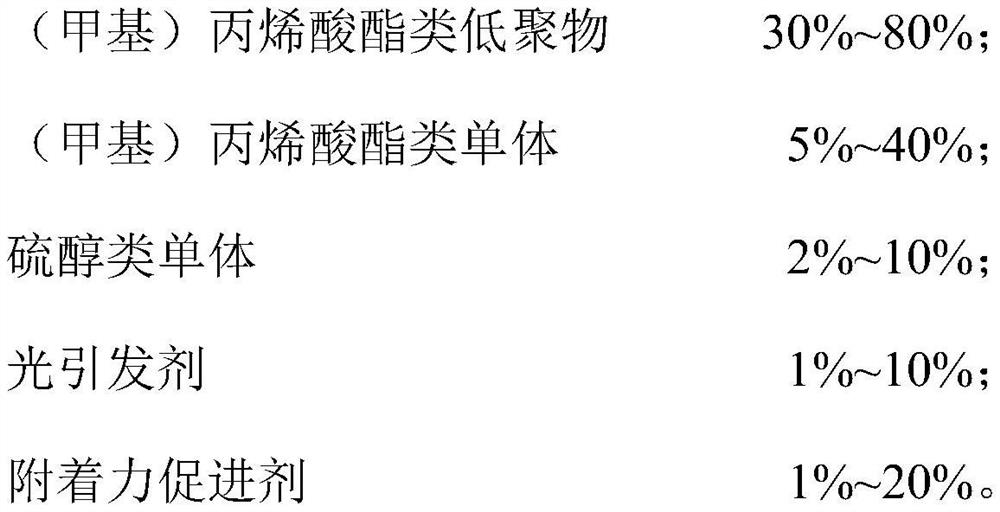

Method used

Image

Examples

Embodiment Construction

[0021] In the following description, for purposes of explanation and to have a comprehensive understanding of the present invention, numerous specific details are set forth, however, it will be obvious to those skilled in the art that the present invention can be practiced without these specific details. . The illustrative example embodiments of the present invention have been set forth for purposes of illustration only, and are not intended to be limiting of the present invention. Therefore, the protection scope of the present invention is not limited by the specific embodiments, but only by the scope of the appended claims.

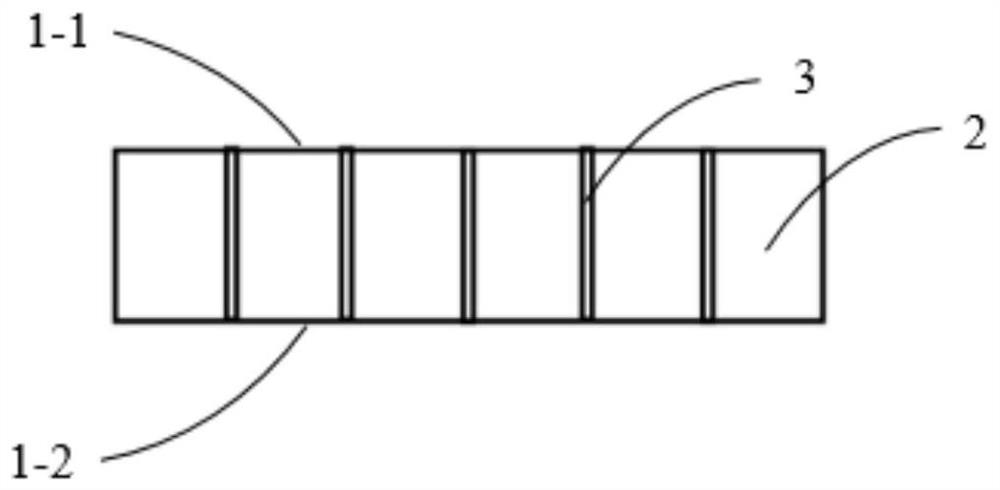

[0022] As stated in the prior art, currently bistable dimming products are mainly used in rigid glass substrates, which cannot be cut arbitrarily, and cannot be produced and transported roll-to-roll. To realize the thin film of bistable dimming products, it is necessary to provide a The flexible support structure, at the same time, this flexible suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com