Antibacterial and deodorant foaming insole containing pearl hemp and preparation method of antibacterial and deodorant foaming insole

A pearl and insole technology, applied in the field of insoles, can solve the problems of long-term sustained release and uneven distribution of active ingredients, and achieve the effects of reducing burr, improving skin-friendly and antibacterial properties, and promoting blood circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

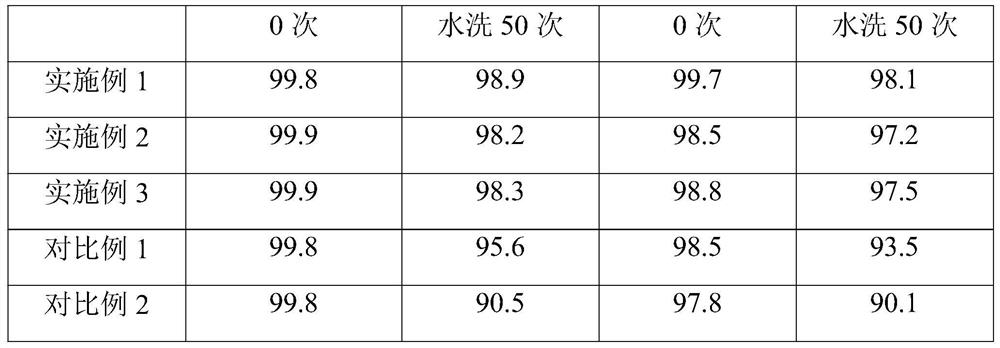

Embodiment 1

[0036] (1) Preparation of foot layer fabric

[0037] After the bamboo vinegar stock solution was filtered with diatomaceous earth, it was distilled under reduced pressure at 50° C. for 5 h to obtain a distillate, which was used to prepare a bamboo vinegar treatment solution. Soak the flax fibers in the bamboo vinegar treatment solution at 45°C for 10 minutes, mix them with pearl fibers in a weight ratio of 4:6 and add them to the mixer after drying, and then spin them into single yarns, twist them into yarns, and yarns Weaving into gray cloth to prepare the pearl and linen mixed fabric for the foot layer.

[0038] (2) Preparation of foam layer

[0039] S1. Pretreatment of attapulgite: roast 50 parts of attapulgite at 200°C for 1 hour, then disperse it in 10% hydrochloric acid, soak it for 2 hours, dry it, put it into an ultrafine mill and grind it to 80-100 Purpose particle, the weight volume ratio of described attapulgite and hydrochloric acid is 1g: 10mL;

[0040] S2. Gri...

Embodiment 2

[0045] (1) Preparation of the foot layer

[0046] After the bamboo vinegar stock solution was filtered with diatomaceous earth, it was distilled under reduced pressure at 80° C. for 3 h to obtain a distillate, which was used to prepare a bamboo vinegar treatment solution. Soak the jute fibers in the bamboo vinegar treatment solution at 70°C for 30 minutes, mix them with pearl fibers in a weight ratio of 5:5 and add them to the mixer after drying, and then spin them into single yarns, twist them into yarns, and yarns Weaving into gray cloth to prepare the pearl and linen mixed fabric for the foot layer.

[0047] (2) Preparation of foam layer

[0048] S1. Pretreatment of attapulgite: roast 60 parts of attapulgite at 400°C for 3 hours, then disperse it in 20% hydrochloric acid, soak it for 5 hours, dry it, put it into an ultrafine mill and grind it into 80-100 Purpose particle, the weight volume ratio of described attapulgite and hydrochloric acid is 1g: 15mL;

[0049] S2. Gri...

Embodiment 3

[0054] (1) Preparation of the foot layer

[0055] After the bamboo vinegar stock solution was filtered with diatomaceous earth, it was distilled under reduced pressure at 65° C. for 3 h to obtain a distillate, which was used to prepare a bamboo vinegar treatment solution. Soak the hemp fiber in the bamboo vinegar treatment solution at 56°C for 25 minutes, mix it with the pearl fiber in a weight ratio of 6:4 and add it to the mixer after drying, and then spin it into single yarn, double twist into yarn, yarn Weaving into gray cloth to prepare the pearl and linen mixed fabric for the foot layer.

[0056] (2) Preparation of foam layer

[0057] S1. Pretreatment of attapulgite: roast 55 parts of attapulgite at 350°C for 1.5h, then disperse it in 15% hydrochloric acid, soak it for 4h, dry it, put it into an ultrafine mill and grind it into 80- 100 mesh particles, the weight volume ratio of the attapulgite and hydrochloric acid is 1g: 12mL;

[0058] S2. Grinding and pulverizing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com