Soaking type non-stick pan

A non-stick pan and non-stick coating technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve problems such as large temperature difference, overheating damage of non-stick coating, coating peeling off, etc., to improve toughness Strength, increase bonding strength, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

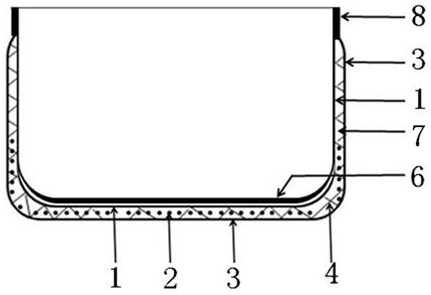

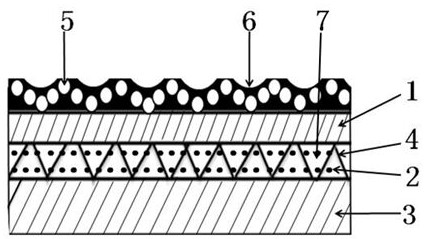

[0043] Such as figure 1 , figure 2 The soaking non-stick pan shown includes an inner pot body 1 , a heat-conducting working fluid 2 , an outer pot body 3 , a porous plate 4 , a wire mesh, and a non-stick coating 6 .

[0044] The manufacturing materials of the inner pot body 1 and the outer pot body 3 are metal plates. The metal plate is pressed into the outer pot body 3 and the inner pot body 1 through a mold, and the specifications of the outer pot body 3 and the inner pot body 1 are correspondingly matched.

[0045] The porous plate 4 is a metal mesh; the thickness of the metal mesh of the porous plate 4 is 3mm, the diameter of the wires of the metal mesh is 1.5mm, and the distance between the metal wires is 3mm.

[0046] The heat-conducting working medium 2 is water, and the volume of water accounts for 15% of the volume of the porous cavity 7 of the porous plate 4 .

[0047] The wire mesh is woven by wires 5, the diameter of the wires 5 of the wire mesh is 0.03 mm, and...

Embodiment 2

[0062] Such as figure 1 , figure 2 The shown uniform non-stick baking pan includes an inner pot body 1 , a heat-conducting working medium 2 , an outer pot body 3 , a porous plate 4 , a wire mesh, and a non-stick coating 6 .

[0063] The combination structure of the soaking non-stick baking pan in Example 2 and the soaking non-stick pan introduced in Example 1 will not be repeated here.

[0064] Such as figure 1 , figure 2 The wire mesh shown is woven from wires 5 .

[0065] The porous plate 4 is metal foam, and the thickness of the metal foam is 3mm.

[0066] The heat-conducting working medium 2 is heat-conducting oil.

[0067] The combined structure of the inner pot body 1, the heat-conducting working medium 2, the outer pot body 3 and the porous plate 4 is fixed as an integrated pot body.

[0068] Step 1, the metal foam of the porous plate 4 is pasted on the outer pot body 3 .

[0069] Step 2, the wire mesh is fixed on the inner pot body 1 .

[0070] Step 3: The in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com