Ceramic membrane, chemical grafting modification method and application

A technology of chemical grafting and grafting modifier, applied in the field of membrane material modification, can solve the problems of dependence, limited chemical grafting modification methods, narrowing of membrane pore size and porosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

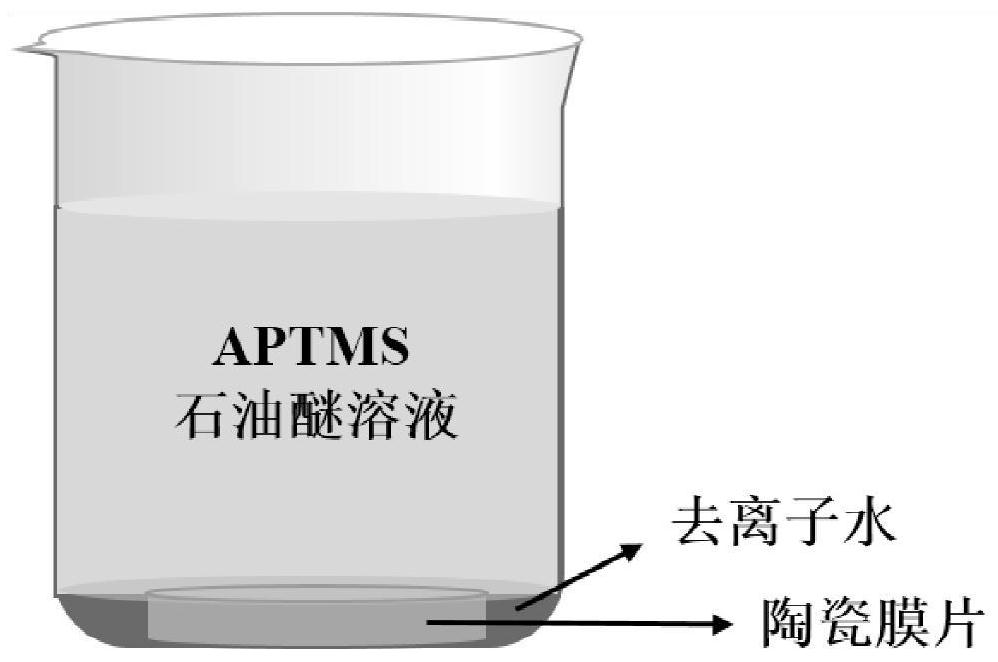

[0047] A sheet-type zirconia ceramic nanofiltration membrane (diameter 3 cm, film thickness 2 mm) with an average pore diameter of 2 nm was cleaned with deionized water, and dried at 110° C. for 6 hours. Dissolve 3-aminopropyltriethoxysilane in petroleum ether to prepare a 10 mmol / L modified solution, and stir evenly at room temperature. Through vacuum filtration, the ceramic membrane pores are filled with water. The wetted ceramic membrane was placed in a beaker, the bottom layer was put into deionized water, and the upper layer was poured into the modified petroleum ether solution. The surface of the ceramic membrane was at the interface of the two phases. Modified at 35°C for 4 hours. After the graft modification was completed, the membrane was taken out, the unreacted modifying reagent was washed away with ethanol, and dried at 110°C to obtain a surface-charged modified ceramic nanofiltration membrane. The structure of 3-aminopropyltriethoxysilane is as follows:

[0048]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com